Label printers

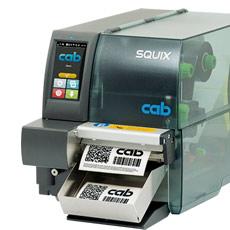

SQUIX

Flexible printers for industrial applications

- Reliable and quick printing

- Accurate print images

- Easy to operate

- Compact design

- Maximum quality standards

They find use in various areas of use. They have been developed with consistent focus on intuitive usability and highly reliable processing.

Print mechanics and chassis are made of high-quality materials and match perfectly in design and function. A wide range of peripherals and software enable user-specific solutions.

The rugged printers stand up to any demand, whether operated stand-alone, with a PC or in a network. Print jobs are performed quickly and labels are provided straight away thanks to a high-speed processor.

Sample applications

PCB

Type plates

Cardboard and pallets

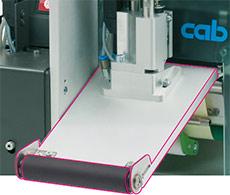

Label printers guiding materials aligned to the left

Optimum printing in matters of different widths and materials

Slim ones

for printing small labels

| Label printer | SQUIX 2 | |

|---|---|---|

| Print resolution dpi | 300 | 600 |

| Print speed mm/s max. | 250 | 150 |

| Print width mm max. | 56.9 | 54.1 |

Universal ones

Best-selling industrial units, providing a wide range of accessories

| Label printer | SQUIX 4.3 | SQUIX 4 | ||

|---|---|---|---|---|

| Print resolution dpi | 203 | 300 | 300 | 600 |

| Print speed mm/s max. | 300 | 300 | 300 | 150 |

| Print width mm max. | 104 | 108.4 | 105.7 | 105.7 |

A cutter can be provided integral to a basic unit.

Wide ones

to print Odette, UCC and GS1 labels in logistics operations

| Label printer | SQUIX 6.3 | |

|---|---|---|

| Print resolution dpi | 203 | 300 |

| Print speed mm/s max. | 250 | 250 |

| Print width mm max. | 168 | 162.6 |

Extra wide ones

for printing pallet and drum labels

| Label printer | SQUIX 8.3 |

|---|---|

| Print resolution dpi | 300 |

| Print speed mm/s max. | 150 |

| Print width mm max. | 216 |

Basic units provide a tear-off plate

Printed labels or continuous materials, wound on a roll or fanfold, can be torn off on a jagged plate.

Cutting a material is another option, so is external rewinding.

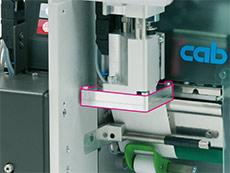

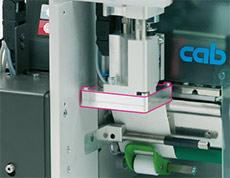

Peel-off units provide an internal rewinder

Dispense adds to the features of a basic unit. Printed labels are peeled off their liner and can be removed by hand or by an applicator.

See also:

SQUIX label printers with centered material guide

Material guide

Material guide

centered

SQUIX 4 M

SQUIX 4 M

especially for very small labels or slim continuous materials

SQUIX 4 MT

SQUIX 4 MT

especially for continuous textil materials

SOTI Connect software enables label printers be configured and managed centrally.

The control panel of our printers can be operated in over 30 languages

Label printers guiding materials aligned to the left

- SQUIX 4 P peel-off printer

providing an internal rewinder

1 Hinged cover

Material stock can be checked and printer processes be followed through a large panoramic window.

2 Plungers

One is fixed next to the chassis inside. The other can be aligned to the outside margin of a label for optimum print images.

3 Metal chassis

It is the base to assemble components. Made of cast aluminum

4 Print roller coating

Synthetic rubber is standard, enabling highly accurate print images. Silicone is an option if aiming for extra long life cycles.

5 Label dispense

Labels are separated on a peel-off plate from their liner. A powered guide roller and a pinch roller enable highly accurate processes when printing and applying labels.

6 Peripheral port

Additional modules can be plugged easily and quickly to a unit and fixed with a screw.

7 Ribbon retainer

Replacing a ribbon is no big deal thanks to three-part clamping axles.

8 Roll retainer

The spring-mounted margin stop provides a screw cap and enables constant tension while materials are fed.

9 Internal rewinder

Labels or liners with or without a cardboard core can be wound on peel-off units. Handling a material is simplified by a three-part clamping axle.

10 Rocker

Spring mounting and guide rollers made of Teflon reduce traction and improve the accuracy of print images.

11 Material guide

It is assembled to the rocker. By turning the rotary knob, the stop can be aligned to the margin of a label.

Print image accuracy

The smaller a label, the higher are the demands. Print offset can be reduced by ±0.2 mm using slip correction.

Control panel

Self-explanatory symbols simplify settings and enable printers be operated intuitive and easily.

1 LED: Power ON

1 LED: Power ON

2 Status bar: receive data, record data stream, prior warning to a ribbon ending, SD memory card / USB stick plugged, WLAN, Ethernet, USB slave, time

3 Printer status: ready, pause, number of labels printed in a print job, label peeled off, awaiting external start signal

4 USB port for plugging a service key or a memory stick, to transfer data to the IFFS memory

5 Operation

Cutter / perforation cutter: cutting a material

Cutter / perforation cutter: cutting a material

External rewinder: label rolls wound outside or inside

Applicator: print and apply labels in individual steps

Tear-off mode / peel-off mode: print a label

Tear-off mode: label backfeed

Tear-off mode: label backfeed

Jump to menu

Jump to menu

Stop and delete all print jobs

Stop and delete all print jobs

Reprint

Reprint

Label feed

Label feed

Suspend and continue a print job

Suspend and continue a print job

vergrößern

vergrößernSetup

vergrößern

vergrößernPrinting parameters

vergrößern

vergrößernPrint position Y

vergrößern

vergrößernPrint speed

vergrößern

vergrößernVideo tutorials

External control panel

If the control panel of a printer cannot be accessed, an additional external one can be plugged.

Same functionality as on the printer

Landscape or portrait mode

Operability as targeted, either on an external panel or on a printer

USB 2.0 Hi-Speed device for plugging a printer

1 LED: Power ON

2 USB port for plugging a service key or a memory stick, to transfer data to the IFFS memory

3 cab provides specified USB cables for power supply. Lengths are 1.8 m to 16 m

Print heads

A print head can be replaced by any other one, provided they are of equal width. They are detected by the CPU and calibrated.

Major data such as operational performances, maximum operational temperatures and heating are kept in memory by the print head. The data can be read at the premise.

Print heads provided for SQUIX 2, SQUIX 4 - 300, 600 dpi

sharp-edged print images

small fonts, graphics on typeplates

printing on materials that imply high energy needs

Print heads provided for SQUIX 4.3, SQUIX 6.3 - 203, 300 dpi

Print heads provided for SQUIX 8.3 - 300 dpi

durable, printing in harsh environments, direct thermal printing

Maintenance

Label sensors

They can be unlocked by touch and pulled out for cleaning.

Print heads

They are easy to replace in few steps. In general, no adjustments are required.

Print rollers

They are quick and easy to loosen for cleaning or removal using a screw.

All-purpose tool

It is provided close at hand on a unit for replacing components and assembling periphery.

SOTI Connect software enables label printers be configured and managed centrally.

The control panel of our printers can be operated in over 30 languages

Label printers guiding materials aligned to the left

Technical data SQUIX: all models in comparision (PDF)

typical

typical  possible

possible  standard

standard  option

option

| 1.1, 1.2 | 1.3, 1.4 | 1.5, 1.6 | 1.7, 1.8 | ||||||

| Type | SQUIX 2 | SQUIX 4.3 | SQUIX 4 | SQUIX 6.3 | SQUIX 8.3 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Print method: Thermal transfer |  |

|

|

|

|

|

|

|

|

| Print method: Direct thermal |  |

- |  |

|

|

- |  |

|

|

| Print resolutiondpi | 300 | 600 | 203 | 300 | 300 | 600 | 203 | 300 | 300 |

| Print speed mm/s max. | 250 | 150 | 300 | 300 | 300 | 150 | 250 | 250 | 150 |

| Print width mm max. | 56.9 | 54.1 | 104 | 108.4 | 105.7 | 105.7 | 168 | 162.6 | 216 |

| Print length mm max. | 12,000 | 3,000 | 13,500 | 6,000 | 6,000 | 1,500 | 9,000 | 4,000 | 3,000 |

| Initial print Distance to locating edge mm | 2 | 2.8 | 1.2 | 2 | 0.5 | 3.2 | 2 | ||

| UHF RFID | |||||||||

| UHF RFID module | - |  |

|

|

|||||

| Material1) | |||||||||

| Paper, cardboard, synthetics PET, PE, PP, PI, PVC, PU, acrylate, Tyvec |  |

|

|

|

|||||

| RFID labels according to separate specification | - |  |

|

|

|||||

| Shrink tube ready for use | - |  |

- | - | |||||

| Shrink tube continuous, pressed |  |

|

- | - | |||||

| Textile tape |  |

|

- | - | |||||

| Finishing Roll, fanfold |  |

|

|

|

|||||

| Finishing Roll diameter mm max. | 205 | ||||||||

| Finishing Core diametermm | 38.1 - 76 | ||||||||

| Finishing Winding | outside or inside | ||||||||

| Label Widthmm | 4 - 63 | 20 - 116 | 46 - 176 | 46 - 220 | |||||

| Label Height no label backfeed2) mm at least | 4 | 4 | 6 | 25 | |||||

| Label Height label backfeed2) mm at least | 4 | 6 | 12 | 25 | |||||

| Label Height label backfeed, peel-offmm at least | 6 | 6 | 12 | 25 | |||||

| Label Thicknessmm | 0.03-0.6 | 0.05 - 0.6 | |||||||

| Liner Widthmm | 24 - 67 | 24 - 120 | 50 - 180 | 50 - 235 | |||||

| Liner Thicknessmm | 0.03 - 0.16 | 0,05 - 0,16 | |||||||

| Continuous Widthmm | 24 - 67 | 24 - 120 | 50 - 180 | 50 - 235 | |||||

| Continuous Thicknessmm | 0.03 - 0.5 | ||||||||

| Continuous Weight (cardboard) g/m2 max. | 300 | ||||||||

| Shrink tube Width ready for use mm max. | - | 120 | - | - | |||||

| Shrink tube Width continuous, pressed mm | 24 - 67 | 24 - 85 | - | - | |||||

| Shrink tube Thickness mm max. | 1.1 | 1.1 | - | - | |||||

| Ribbon3) Color layer | outside or inside | ||||||||

| Ribbon Roll diameter mm max. | 80 | ||||||||

| Ribbon Core diameter mm | 25,4 | ||||||||

| Ribbon Length m max. | 600 | 360 | |||||||

| Ribbon Widthmm | 25 - 67 | 25 - 114 | 50 - 170 | 220 | |||||

| Internal rewinder provided on peel-off units | |||||||||

| Outside diameter mm max. | 142 | ||||||||

| Core diametermm | 40 | ||||||||

| Winding | outside | ||||||||

| Printer dimensions, weights | |||||||||

| Width x Height x Depthmm | 200 x 288 x 460 | 252 x 288 x 460 | 312 x 288 x 460 | 352 x 288 x 460 | |||||

| Weightkg | 9 | 10 | 14 | 15 | |||||

| Label sensors, position indicators | |||||||||

| Transmissive sensor detecting | labels, punch marks, materials ending, print marks on translucent materials | ||||||||

| Reflective sensor from below or top detecting | labels, materials ending, print marks on non-translucent materials | ||||||||

| Sensor distance to locating edge aligned to the left mm | 5 - 26 | 5 - 60 | 5 - 60 | 5 - 60 | |||||

| Material passage mm max. | 2 (5 are an option) | ||||||||

| Interfaces | |||||||||

| RS232-C 1,200 to 230,400 baud / 8 bit |  |

||||||||

| USB 2.0 Hi-Speed device for plugging a PC |  |

||||||||

| Ethernet 10/100 Mbit/s IPv4 and IPv6 |

LPD, RawIP printing, SOAP web service, OPC UA, WebDAV, DHCP, HTTP/HTTPS, FTP/FTPS, TIME, NTP, Zeroconf, SNMP, SMTP, VNC | ||||||||

| 2 USB hosts on the control panel, 2 USB hosts on the back of a unit |

Service key, USB stick, USB WLAN stick, USB WLAN stick with a rod antenna, keyboard, barcode scanner, external control panel (on back only) | ||||||||

| USB host, 24 VDC, for peripheral plugging |  |

||||||||

| Digital I/O interface providing 8 inputs and 8 outputs |  |

||||||||

| Operating data | |||||||||

| Voltage | 100 - 240 VAC ~ 50/60 Hz, PFC | ||||||||

| Power consumption | <10 W in standby / 100 W in typical operation / max. 200 W | ||||||||

| Temperature / humidity: Operation | +5 - 40°C / 10 - 85 %, not condensing | ||||||||

| Temperature / humidity: Stock | 0 - 60°C / 20 - 85 %, not condensing | ||||||||

| Temperature / humidity: Transport | –25 - 60°C / 20 - 85 %, not condensing | ||||||||

| Approvals | CE, UKCA, FCC Class A, ICES-3, cULus, CB, CCC, BIS, BSMI, KC-Mark, Mexico Reg. → BIS, KC-Mark not provided for SQUIX 8.3 |

||||||||

| Control panel | |||||||||

| Color LCD touchscreen Diagonal ″ | 4.3 | ||||||||

| Color LCD touchscreen Resolution Width x Height px | 272 x 480 | ||||||||

SOTI Connect software enables label printers be configured and managed centrally.

The control panel of our printers can be operated in over 30 languages

An overview of which accessories are compatible with which device version and which accessories can be adopted from the A + series you can find in the product brochure.

Video: Label printers SQUIX - designed for industrial application

Powered by YouTube. See all cab videos: cab Channel auf YouTube.

Other formats: Label printer SQUIX - designed for industrial application (MPEG-4; 218 MB)

SQUIX case studies

Play

Play

Formula Student: SQUIX dynamically imprints names on acetate silk

Read case study

Play

Play

20 years united by wine labeling: Vier Jahreszeiten winegrowers and cab

Read case study

SQUIX Accessories

Play

Play

Scanner CC200-SQ to detect linear 1D barcodes, 2D and stacked codes

Play

Play

Cutter CSQ 400 provided for all basic SQUIX 4 devices

Play

Play

External unwinders EU

cab Video Tutorials SQUIX

Play

Play

SQUIX Dispensing version: Rewind labels internally

Play

Play

SQUIX Dispensing version: Remove internally wound labels

Play

Play

SQUIX Dispensing version: Dispensing labels

Play

Play

SQUIX Dispensing version : Changing dispense plate

Play

Play

SQUIX: Install WLAN stick

Documentation

-

Catalogs

-

Title Format Version Last change Language SQUIX

PDF - 6.88 MB 05/2025 14/05/2025 English Overview Product Marking

PDF - 6.61 MB 05/2025 15/05/2025 English UHF RFID label printers

PX Q | HERMES Q | XD Q | SQUIXPDF - 860 KB 03/2025 18/03/2025 English

-

-

Operation Manuals

-

Title Format Version Last change Language Instructions SQUIX

PDF - 4.17 MB 05/2025 27/05/2025 English -

Other languages

-

Title Format Version Last change Language Инструкция за експлоатация SQUIX

PDF - 4.23 MB 05/2025 27/05/2025 Български 操作手冊 條碼打印機 SQUIX

PDF - 4.96 MB 05/2025 27/05/2025 简体字 操作手冊 條碼印表機 SQUIX

PDF - 5.05 MB 05/2025 27/05/2025 繁體字 Upute za uporabu SQUIX

PDF - 4.19 MB 05/2025 27/05/2025 Hrvatski Návod k obsluze SQUIX

PDF - 4.20 MB 05/2025 27/05/2025 Čeština Driftsvejledning SQUIX

PDF - 4.15 MB 05/2025 27/05/2025 Dansk Gebruiksaanwijzing SQUIX

PDF - 4.20 MB 08/2024 26/08/2024 Nederlands Kasutusjuhend SQUIX

PDF - 4.15 MB 05/2025 27/05/2025 Eesti Käyttöohje SQUIX

PDF - 4.12 MB 05/2025 27/05/2025 Suomi Οδηγίες λειτουργίας SQUIX

PDF - 4.23 MB 05/2025 27/05/2025 ελληνικά Üzemeltetési útmutató SQUIX

PDF - 4.20 MB 05/2025 27/05/2025 Magyar 取扱説明書 SQUIX

PDF - 4.73 MB 05/2025 27/05/2025 日本語 사용 설명서 SQUIX

PDF - 4.61 MB 05/2025 27/05/2025 한국어 Lietošanas pamācība SQUIX

PDF - 4.20 MB 05/2025 27/05/2025 Latviešu Naudojimo instrukcija SQUIX

PDF - 4.20 MB 05/2025 27/05/2025 Lietuvių Bruksanvisning SQUIX

PDF - 4.15 MB 05/2025 27/05/2025 Norsk Instrukcja obsługi SQUIX

PDF - 4.21 MB 05/2025 27/05/2025 Polski Manual de instruções SQUIX

PDF - 4.19 MB 05/2025 27/05/2025 Português Instrucţiuni de utilizare SQUIX

PDF - 4.20 MB 05/2025 27/05/2025 Română Руководство по эксплуатации SQUIX

PDF - 4.23 MB 05/2025 27/05/2025 Pусский Návod na obsluhu SQUIX

PDF - 4.20 MB 05/2025 27/05/2025 Slovenský Betriebsanleitung SQUIX

PDF - 4.16 MB 05/2025 27/05/2025 Deutsch Instructions d'utilisation SQUIX

PDF - 4.18 MB 05/2025 27/05/2025 Français Istruzioni per l’uso SQUIX

PDF - 4.18 MB 05/2025 27/05/2025 Italiano Navodila za uporabo SQUIX

PDF - 4.19 MB 05/2025 27/05/2025 Slovenščina Instrucciones SQUIX

PDF - 4.18 MB 05/2025 27/05/2025 Español Bruksanvisning SQUIX

PDF - 4.15 MB 05/2025 27/05/2025 Svensk คู่มือการใช้งาน SQUIX

PDF - 4.27 MB 05/2025 27/05/2025 ภาษาไทย İşletim Kılavuzu SQUIX

PDF - 4.20 MB 05/2025 27/05/2025 Türkçe

-

-

-

EU Declaration of Conformity

-

Title Format Version Last change Language EU Declaration of Conformity SQUIX

PDF - 72 KB 07/2022 02/02/2023 English -

Other languages

-

Title Format Version Last change Language ЕС декларация за съответствие SQUIX

PDF - 77 KB 07/2022 26/07/2022 Български EU izjava o sukladnosti SQUIX

PDF - 70 KB 07/2022 26/07/2022 Hrvatski EU prohlášení o shodě SQUIX

PDF - 71 KB 07/2022 26/07/2022 Čeština EU-overensstemmelseserklæring SQUIX

PDF - 71 KB 07/2022 26/07/2022 Dansk EU-conformiteitsverklaring SQUIX

PDF - 72 KB 07/2022 26/07/2022 Nederlands ELi vastavusdeklaratsioon SQUIX

PDF - 69 KB 07/2022 15/07/2022 Eesti EU-vaatimustenmukaisuusvakuutus SQUIX

PDF - 69 KB 07/2022 26/07/2022 Suomi Déclaration UE de conformité SQUIX

PDF - 71 KB 07/2022 15/07/2022 Français Δήλωση συμμόρφωσης ΕΕ SQUIX

PDF - 90 KB 07/2022 26/07/2022 ελληνικά EU-megfelelőségi nyilatkozat SQUIX

PDF - 72 KB 07/2022 26/07/2022 Magyar ES atbilstības deklarācija SQUIX

PDF - 72 KB 07/2022 15/07/2022 Latviešu ES atitikties deklaracija SQUIX

PDF - 71 KB 07/2022 15/07/2022 Lietuvių EU-samsvarserklæring SQUIX

PDF - 72 KB 07/2022 26/07/2022 Norsk Deklaracja zgodności UE SQUIX

PDF - 72 KB 07/2022 15/07/2022 Polski Declaração UE de conformidade SQUIX

PDF - 72 KB 07/2022 15/07/2022 Português Declarația UE de conformitate SQUIX

PDF - 71 KB 07/2022 15/07/2022 Română Декларация соответствия требованиям ЕС SQUIX

PDF - 79 KB 07/2022 26/07/2022 Pусский EÚ vyhlásenie o zhode SQUIX

PDF - 72 KB 07/2022 26/07/2022 Slovenský Izjava EU o skladnosti SQUIX

PDF - 70 KB 07/2022 26/07/2022 Slovenščina EU-försäkran om överensstämmelse SQUIX

PDF - 70 KB 07/2022 26/07/2022 Svensk AB-Uyumluluk Bildirimi SQUIX

PDF - 72 KB 07/2022 15/07/2022 Türkçe Dichiarazione di conformità UE SQUIX

PDF - 71 KB 07/2022 15/07/2022 Italiano EU-Konformitätserklärung SQUIX

PDF - 73 KB 07/2022 15/07/2022 Deutsch

-

-

-

UKCA Declaration of Conformity

-

Title Format Version Last change Language UKCA Declaration of Conformity

PDF - 71 KB 10/2022 05/10/2022 English

-

-

Interface Descriptions

-

Information on the interface type can be found on the original cab packaging, in the printer status report after installation or as a label next to the SUB-D connection.

Title Format Version Last change Language Interface Description I/O 24V25-1

PDF - 334 KB 05/2020 06/02/2024 English Interface Description I/O 24V25-2 and I/O 24V25-3

PDF - 278 KB 05/2025 16/05/2025 English Interface Description I/O 24V25-4

PDF - 278 KB 05/2025 16/05/2025 English -

Other languages

-

Title Format Version Last change Language Description de l'interface I/O 24V25-4

PDF - 301 KB 05/2025 16/05/2025 Français Description des interfaces I/O 24V25-2 et I/O 24V25-3

PDF - 302 KB 05/2025 16/05/2025 Français Schnittstellenbeschreibung I/O 24V25-1

PDF - 324 KB 05/2020 01/03/2023 Deutsch Schnittstellenbeschreibung I/O 24V25-2 und I/O 24V25-3

PDF - 265 KB 05/2025 16/05/2025 Deutsch Schnittstellenbeschreibung I/O 24V25-4

PDF - 268 KB 05/2025 16/05/2025 Deutsch

-

-

-

Configuration Manuals

-

Title Format Version Last change Language Configuration manual cab Label Printers

from SN 14089PDF - 2.57 MB 08/2024 19/08/2024 English Configuration manual SQUIX

up to SN 14088PDF - 1.64 MB 08/2017 03/12/2020 English -

Other languages

-

Title Format Version Last change Language Konfigurationsanleitung cab-Etikettendrucker

ab SN 14089PDF - 2.60 MB 08/2024 19/08/2024 Deutsch Konfigurationsanleitung SQUIX

bis SN 14088PDF - 1.61 MB 08/2017 03/12/2020 Deutsch Manuel de configuration imprimantes d'étiquettes cab

à partir du numéro de série 0014089PDF - 2.66 MB 08/2024 19/08/2024 Français

-

-

-

Programming

-

Title Format Version Last change Language Programming Manual JScript

for SQUIX, MACH 4S, EOS2, EOS5, XC Q, XD Q, HERMES Q, PX Q, AXON1, AXON 2, A+, HERMES+, A-Series, EOS1/4, MACH4, XD, XCPDF - 4.30 MB 05/2025 23/05/2025 English ZPL Emulation with cab printers

PDF - 2.28 MB 05/2025 23/05/2025 English Brief introduction to cab printer programming

PDF - 7.47 MB 04/2022 15/01/2025 English cab Download Converter (download.exe)

Converts image, font and database files into the JScript download data format.

Install MS Visual C++ 2010 Redistributable if not available on your system.ZIP - 9 KB 2.3 25/10/2024 – cab Remote Control

Remote control of cab systems for label printing / Fernsteuerung von cab Drucksystemen - HERMES Q, SQUIX, PX QZIP - 3.50 MB 2021/07 15/01/2025 English/Deutsch cabPROTECT - Data security in label printing

PDF - 472 KB 06/2024 20/06/2024 English Connecting cab printing systems to SAP®

CompendiumPDF - 4.45 MB 01/2025 11/02/2025 English Networked labeling with OPC UA

cab and the Smart FactoryPDF - 1.12 MB 03/2019 15/01/2025 English PLC Programmer's Guide HERMES Q, SQUIX, XD Q, PX Q

with label layouts and programming examplesZIP - 16.17 MB 06/2020 15/01/2025 English Programming Manual abc Basic Compiler

for cab printersPDF - 755 KB 11/2024 29/11/2024 English -

Other languages

-

Title Format Version Last change Language Anbindung von cab Drucksystemen an SAP®

KompendiumPDF - 4.55 MB 01/2025 11/02/2025 Deutsch cabPROTECT - Datensicherheit beim Etikettendruck

PDF - 475 KB 06/2024 20/06/2024 Deutsch Kurze Einführung in die cab Druckerprogrammierung

PDF - 7.50 MB 04/2022 12/04/2022 Deutsch Marquage en réseau avec OPC UA

cab et l'usine intelligentePDF - 745 KB 01/2022 23/10/2024 Français SPS Programmieranleitung HERMES Q, SQUIX, XD Q, PX Q

mit Etikettenlayouts und BeispielprogrammenZIP - 16.22 MB 06/2020 18/04/2024 Deutsch Vernetzt kennzeichnen mit OPC UA

cab und die intelligente FabrikPDF - 1.13 MB 03/2019 28/01/2021 Deutsch

-

-

-

Service Manuals

-

Title Format Version Last change Language Service Manual SQUIX

PDF - 2.75 MB 05/2025 20/05/2025 English -

Other languages

-

Title Format Version Last change Language Serviceanleitung SQUIX

PDF - 2.77 MB 05/2025 20/05/2025 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List SQUIX 2

PDF - 1.03 MB 01/2024 04/01/2024 English Spare Parts List SQUIX 4 / SQUIX 4.3

PDF - 1.83 MB 05/2025 15/05/2025 English Spare Parts List SQUIX 6.3

PDF - 1.06 MB 01/2024 04/01/2024 English Spare Parts List SQUIX 8.3

PDF - 1.13 MB 05/2025 28/05/2025 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste SQUIX 2

PDF - 1.03 MB 01/2024 04/01/2024 Deutsch Ersatzteilliste SQUIX 4 / SQUIX 4.3

PDF - 1.84 MB 05/2025 15/05/2025 Deutsch Ersatzteilliste SQUIX 6.3

PDF - 1.06 MB 01/2024 04/01/2024 Deutsch Ersatzteilliste SQUIX 8.3

PDF - 1.13 MB 05/2025 28/05/2025 Deutsch

-

-

-

Assembly Instructions Spare Parts

-

Title Format Version Last change Language 9004105 | Druckkopfwechsel / Printhead Replacement: SQUIX, HERMES Q, MACH 4S, EOS2, EOS5, PX Q, AXON1, XC Q, XD Q

PDF - 5.70 MB 06/2024 18/06/2024 English/Deutsch

-

-

cab Video Tutorials

-

Title Format Version Last change Language How to insert labels in SQUIX label printers (base version)?

– – 19/12/2018 – How to insert fanfold labels in SQUIX label printers?

– – 21/11/2023 – How to insert ribbon in SQUIX label printers (base version)?

– – 19/12/2018 – How to clean print head at SQUIX label printers?

– – 19/12/2018 – How to clean print roller at SQUIX label printer?

– – 22/08/2023 – How to change the print roller at SQUIX label printer?

– – 19/12/2018 – How to rewind labels internally with SQUIX peel-off version?

– – 19/12/2018 – How to remove internally wound labels at SQUIX peel-off version?

– – 19/12/2018 – How to insert labels in SQUIX label printers (peel-off version)?

– – 19/12/2018 – How to change the dispense plate at SQUIX label printers?

– – 19/12/2018 – How to install wlan stick at SQUIX label printers?

– – 19/12/2018 –

-

-

Feed Path Schemes

-

Title Format Version Last change Language Feed Path Scheme SQUIX 2

Open the file in Adobe Acrobat Reader to interactively adapt the schemas to the specific application.PDF - 217 KB 11/2018 24/05/2023 English Feed Path Scheme SQUIX 4

Open the file in Adobe Acrobat Reader to interactively adapt the schemas to the specific application.PDF - 486 KB 11/2018 24/05/2023 English Feed Path Scheme SQUIX 6.3

Open the file in Adobe Acrobat Reader to interactively adapt the schemas to the specific application.PDF - 222 KB 11/2018 24/05/2023 English -

Other languages

-

Title Format Version Last change Language Einlegeschema SQUIX 2

Öffnen Sie die Datei im Adobe Acrobat Reader, um interaktiv die Schemas an die konkrete Anwendung anzupassen.PDF - 212 KB 11/2018 24/05/2023 Deutsch Einlegeschema SQUIX 4

Öffnen Sie die Datei im Adobe Acrobat Reader, um interaktiv die Schemas an die konkrete Anwendung anzupassen.PDF - 477 KB 11/2018 24/05/2023 Deutsch Einlegeschema SQUIX 6.3

Öffnen Sie die Datei im Adobe Acrobat Reader, um interaktiv die Schemas an die konkrete Anwendung anzupassen.PDF - 211 KB 11/2018 24/05/2023 Deutsch Schémas de mise en place des consommables SQUIX 2

Ouvrez le fichier avec Adobe Reader afin de sélectionner le type de consommables pour obtenir le schéma de mise en place correspondantPDF - 213 KB 11/2018 24/05/2023 Français Schémas de mise en place des consommables SQUIX 4

Ouvrez le fichier avec Adobe Reader afin de sélectionner le type de consommables pour obtenir le schéma de mise en place correspondantPDF - 496 KB 11/2018 24/05/2023 Français Schémas de mise en place des consommables SQUIX 6.3

Ouvrez le fichier avec Adobe Reader afin de sélectionner le type de consommables pour obtenir le schéma de mise en place correspondantPDF - 222 KB 11/2018 24/05/2023 Français

-

-

-

Manuals Accessories

-

Other languages

-

EU Declarations of Conformity - Accessories

-

Other languages

-

Spare Parts Accessories

-

Title Format Version Last change Language Cutter CU200 / CU400 / CU600 / CU800 - Spare Parts List

PDF - 228 KB 09/2022 06/02/2023 English External Rewinder ER1, ER2, ER3 for SQUIX - Spare Parts List

PDF - 482 KB 11/2024 11/11/2024 English External Rewinder ER4, ER6, ER8 - Spare Parts List

PDF - 688 KB 11/2024 11/11/2024 English Perforation Cutter PSQ 403 - Spare Parts List

PDF - 283 KB 01/2025 30/01/2025 English Cutter CSQ 401 / CSQ 402 - Spare Parts List

PDF - 241 KB 01/2025 30/01/2025 English Perforation Cutter PCU400 - Spare Parts List

PDF - 281 KB 10/2018 06/02/2023 English Stacker with Cutter ST400 - Spare Parts List

PDF - 502 KB 10/2018 06/02/2023 English External Unwinder EU4, EU6, EU8 - Spare Parts List

PDF - 263 KB 03/2024 27/03/2024 English -

Other languages

-

Title Format Version Last change Language Externer Abwickler EU4, EU6, EU8 - Ersatzteilliste

PDF - 264 KB 03/2024 27/03/2024 Deutsch Externer Aufwickler ER1, ER2, ER3 für SQUIX - Ersatzteilliste

PDF - 487 KB 11/2024 11/11/2024 Deutsch Externer Aufwickler ER4, ER6, ER8 - Ersatzteilliste

PDF - 668 KB 11/2024 11/11/2024 Deutsch Perforationsmesser PCU400 - Ersatzteilliste

PDF - 300 KB 10/2018 03/12/2020 Deutsch Perforationsmesser PSQ 403 - Ersatzteilliste

PDF - 286 KB 01/2025 30/01/2025 Deutsch Schneidemesser CSQ 401 / CSQ 402 - Ersatzteilliste

PDF - 244 KB 01/2025 30/01/2025 Deutsch Schneidemesser CU200 / CU400 / CU600 / CU800 - Ersatzteilliste

PDF - 231 KB 09/2022 13/09/2022 Deutsch Stapler mit Schneidemesser ST400 - Ersatzteilliste

PDF - 505 KB 10/2018 03/12/2020 Deutsch

-

-

-

Case study

-

Title Format Version Last change Language 20 years united by wine labeling: Vier Jahreszeiten Winzer eG and cab

PDF - 2.96 MB 11/2018 19/11/2018 English Formula Student Germany: SQUIX dynamically imprints names on acetate silk

PDF - 2.09 MB 10/2017 24/10/2017 English HTI, specialist in lab and manufacture automation: Opening, filling and labeling micro-screw tubes

PDF - 650 KB 11/2022 16/11/2022 English Mittelstand 4.0 roadshow: Label printers and dispensers qualify for future technologies

PDF - 1.57 MB 02/2022 09/02/2022 English -

Other languages

-

Title Format Version Last change Language Mittelstand 4.0-Roadshow: Etikettendrucker und -spender befähigen zu Technologien von morgen

PDF - 1.98 MB 02/2022 09/02/2022 Deutsch

-

-

-

Safety data sheets

-

Title Format Version Last change Language Safety Data Sheet Special Cleaner for Glass and Plastic GR1N

PDF - 65 KB 08/2017 23/10/2024 English Safety Data Sheet Special Rubber Cleaner WR1

PDF - 76 KB 12/2017 23/10/2024 English -

Other languages

-

Title Format Version Last change Language Sicherheitsdatenblatt Spezial Glasreiniger und Kunststoffreiniger GR1N

PDF - 156 KB 06/2017 25/08/2022 Deutsch Sicherheitsdatenblatt Spezial-Gummiwalzen-Reiniger WR1

PDF - 173 KB 06/2017 25/08/2022 Deutsch

-

-

3D CAD models

The files are provided in STEP format, which requires CAD software. Follow this link to download a free STP Viewer: VariCAD Viewer (External website).

Select the desired model and click on the link. A short registration follows. cab will handle your personal information as described in our Privacy statement. This information will not be accessible to any third party for marketing purposes. You will receive an email with an activation link and you can download the models.

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Well-trained cab service engineers worldwide support in the maintenance and repair of the devices.

Here you can download firmware, drivers and software. Documentation on label software, printers programming and administration as well as integration of cab printers into SAP systems:

Label software

Software & Drivers

-

Firmware

-

Title Format Version Last change Language Firmware X4

Firmware SQUIX | EOS2 | EOS5 | MACH 4S | XD Q | XC Q | HERMES Q | PX Q | AXONZIP - 53.66 MB 5.46.4 05/06/2025 – cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Release Notes Firmware X4

TXT - 123 KB

TXT - 123 KB

5.00 - 5.46.4 05/06/2025 –

-

-

Firmware periphery

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Firmware applicators SQ, HQ

ZIP - 49 KB 2.1.0 08/04/2025 – Firmware CSQ 401, CSQ 402, PSQ 403, PSQ404

ZIP - 59 KB 3.12.0 08/04/2025 – Firmware I/O 24V25-2, I/O 24V25-3, I/O 5V15-2 and I/O 5V15-3

ZIP - 23 KB 3.2.0 08/04/2025 –

-

-

Drivers

-

Title Format Version Last change Language cab Linux Armv7 - 32 Bit Driver

CUPS Linux Armv7 32bit Driver RPi 2/3/4 (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab Linux Armv8(aarch64) - 64 Bit Driver

CUPS Linux Armv8 64 Bit Driver RPi 3/4 (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab Linux x86 - 32 Bit Driver

CUPS Linux Intel 32bit Driver (min. CUPS 1.2)GZ - 2.81 MB 1.46 23/10/2024 – cab Linux x86 - 64 Bit Driver

CUPS Linux Intel/AMD 64bit Driver (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab MAC OS Driver

Apple® Mac OS 10.15 - 15.4ZIP - 2.97 MB 1.46 01/04/2025 – cab MAC OS X Driver

Apple® Mac OS X 10.6 - 10.14ZIP - 5.82 MB 1.46 23/10/2024 – cab Windows Driver ARCHIV

Vista, Windows 7, Windows 8, Windows 8.1, Windows 10, Windows Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019 - 32/64 Bit CERTIFIEDZIP - 9.37 MB 5.3.03 21/02/2024 – cab Windows Driver NEW

Windows 10, Windows 11, Windows Server 2016, Windows Server 2019, Windows Server 2022 - 64Bit, requires Visual C++ 2022ZIP - 24.01 MB 1.4.1.0 24/03/2025 – cab Windows Driver NEW Release Notes

PDF - 120 KB 1.2.1.20 - 1.4.1.0 24/03/2025 –

-

-

Software

-

Title Format Version Last change Language cab Download Converter (download.exe)

Converts image, font and database files into the JScript download data format.

Install MS Visual C++ 2010 Redistributable if not available on your system.ZIP - 9 KB 2.3 25/10/2024 – cablabel S3 Demo (Free)

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 51.42 MB 1.4.0.9 30/06/2025 – cablabel S3 Lite (Free)

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 68.19 MB 1.4.0.9 26/11/2024 – cablabel S3 Print

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 57.82 MB 1.4.0.9 30/06/2025 – cablabel S3 Pro

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 68.64 MB 1.4.0.9 30/06/2025 – Database Connector

Windows 32 & 64 bitZIP - 10.93 MB 4.3.0.1 25/10/2024 – LogService

for Database ConnectorZIP - 4.15 MB 1.7.1.0 25/10/2024 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Ready to interact with machines and components of different manufacturers in industrial plants.

Interface modeled by cab for robotics operations of tomorrow.

enable labels be rewound internally on peel-off units. A guide plate therefore replaces the peel-off plate.

enable labels be rewound internally on peel-off units. A guide plate therefore replaces the peel-off plate.

Jig to retain a printer unit

Jig to retain a printer unit