Label dispenser

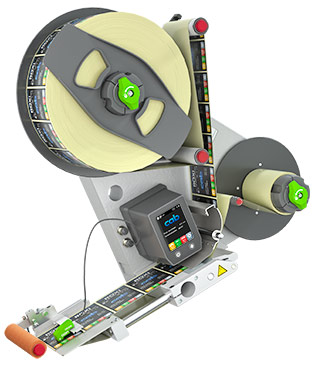

ROXI

for industrial use

Professional at best price

Precise insert labeling

Solid construction, perfect in every way

Advanced electronics and software

Small price − great performance

A future-proof investment

Compact and slim design

Easy to install into production lines

Any assembly

Vertical, horizontal, inclined, dispensing labels to the left or right

High quality and reliability

Tried and tested functional modules assembled Made in Germany

Durable and easy to maintain

Designed for continuous industrial use, Free firmware updates via Ethernet or USB interface

Dynamic speed control

Label web is fed automatically by a masterencoder (rotary or linear) in accordance with the speed of items on a conveyor.

Safety guaranteed

Certified by independently authorized testing labs

Short setup times

Short setup times

Useful accessories

Columns, stands, connecting cables, and many others help with installation ready for use.

Operation panel

Intuitive and easy to operate. Rotatable in steps of 180°, depending on the installation.

Unit configuration with the help of selfexplanatory symbols on the user interface

Quick menues

Extra-fast setting

1 Stop delay

2 Start delay

3 Label web speed

ON / OFF Pre-dispense

4 Status bar

Speed, label winding,

length of a label, WLAN,

start / stop signal

5 Operational and warning notes

Status and menu parameters

6 Counter and diagnostics

Configurable specified to an application

7 Menu options

Menu options

Label web speed

Label web speed

Synchronous with speed of items

System settings

System settings

Display, language, label web ending, interfaces

Label position on item

Label position on item

Multiple labeling enabled

Start condition

User configuration

User configuration

Any number of formats

Backup and restore by a PC

Label web stopped on a demand module

Label web stopped on a demand module

Missing labels detected

Processing an external stop condition

Charge counter

Charge counter

Automatic stop subsequent to a specified number of items

Print settings

Print settings

Control of an external printer or applicator

Servicetools

Servicetools

Maintenance assistance, video tutorials, input and control of digital I/O for service purposes

Firmware

Embedded Linux operating system

- Support 'out-of-the-box' of Open Source bundles and interfaces, such as FTP, SSL, Avahi/Zeroconf

- Regular updates for hotfixes and official CVE security patches

- Comprehensive release notes for each update

Compatible with IXOR highspeed labeling head

- Same codebase as IXOR

- New IXOR features are automatically included in ROXI.

- Identical firmware file for both units

Maintenance and diagnostics

![]()

- Web Interface

- Event log for tracking activities

- Diagnostics documents in standardized XML text format

Interfaces and user-specific features

| USB stick | Web Interface | FTP software | |

|---|---|---|---|

| Access to entire documentation of a unit |

|

|

|

| Backup and restore |  |

|

|

| Configuration reading and import |

|

|

|

| Firmware update |  |

|

Upgrades

- Protocols such as MQTT as well as features like the masterencoder can be unlocked by key (online purchase).

Remote support

- Diagnostics by service staff, using an existing customer network

- Special software oscilloscope, maximum resolution 1 ms, for unlimited use during production

Integral Ethernet protocols for higher-level machine control systems

- MQTT, ModBus TCP

- OPC UA

- Profinet in preparation, available from Oct. 2025

- Access via PLC and an industrial PC to parameters, I/O signals, error messages

Redundancy

- Any number of pairs of label dispensers can be operated redundantly in an Ethernet network.

- While one dispenser actively applies labels onto items, another unit is on standby. In cases of a malfunction on an active unit (e.g. label web ending), the second one takes over immediately.

- It is ensured all items located between the units are labeled.

VNC LAN / WLAN

VNC LAN / WLANRemote control by a

PC, smartphone, tablet

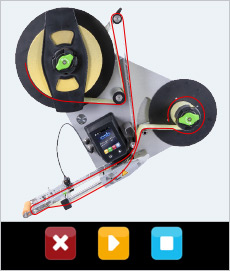

Feed path schemes

Feed path schemesOn display

Interfaces

1 Main switch

2 Cold appliance socket

3 2 USB hosts

for a warning light, an external operation panel, USB / WLAN stick

4 Ethernet

TCP/IP data transmission

5 START

By signal, e.g. a product sensor

6 SYNC

Label web is synchronized by a masterencoder (rotary or linear) to the speed of items on a conveyor.

7 I/O

Compliant to IEC/EN 61131-2, type 1+3

All inputs and outputs protect from reverse polarity.

Outputs are also short-circuit proof.

Digital inputs

Unit ON

Pre-dispense

Start dispensing

Start lock

Error reset

Defined by user

Analog inputs

Speed

Start delay

Stop delay

Digital PNP outputs

Unit ready

Pre-dispense button pressed

Stop label feed

Label feed ON

Label missing on liner

End of label web

Pre-warning to label web ending

Error

Defined by user

8 I/O status indication

8 I/O status indication

Status display of all inputs and outputs

Helpful with initial setup, especially when integrating a label dispenser int o external control systems

Inputs and outputs c an be simulated or forced for testing purposes.

9 PRINT & APPLY

9 PRINT & APPLY

Peripheral interface; Plugging a printer or controlling an applicator with power supply 24VDC, 2A

10 STOP

Plugging a label sensor, optical or inductive detection

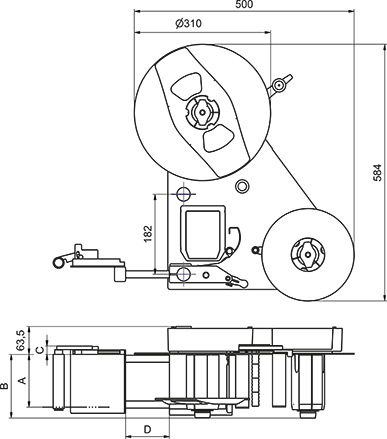

| Label dispenser Type | ROXI 120 | ROXI 180 |

|---|---|---|

| Label web speed m/min max. | 30 | 20 |

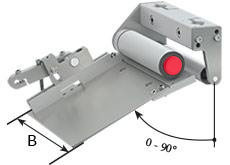

| Installation | vertical / horizontal | |

| Direction to which labels are dispensed | L = to the left, R = to the right | |

| Material1) | ||

| Label on a roll | Paper, synthetics PET, PE, PP, PVC, booklets | |

| Labels Width mm | 10 - 116 | 10 - 176 |

| Labels Lengthmm | 10 - 6,000 | |

| Labels Gap mm at least | 2 | |

| Labels Thickness mm | 0.055 - 1.0 | |

| Liner Width mm | 15 - 120 | 15 - 180 |

| Roll Weightkg max. | 12 | |

| Unwinder Outside diameter mm | 300 | |

| Unwinder Core diameter | 76 | |

| Unwinder Winding | outside or inside | |

| Rewinder Outside diameter mm | 210 | |

| Rewinder Core diametermm | 76 | |

| Label sensor | ||

| Detection of | label margins and materials ending | |

| Distance to locating edge CEONmm | 9 - 62 | 9 - 94 |

| Distance to locating edge GAB 500-1 mm | 7.5 - 17.5 | |

| Distance to locating edge GAB 500-2 mm | 8 | |

| Operating data | ||

| Voltage | 100 - 240 V~, 50 - 60 Hz | |

| Temperature / humidityOperation | 0 - 40 °C / 10 - 85 %, not condensing | |

| Temperature / humidity Stock | 0 - 60°C / 20 - 80 %, not condensing | |

| Temperature / humidity Transport | –25 - 60°C / 20 - 80 %, not condensing | |

| Approvals | CE, FCC Class A, ICES-3 | |

| Approvalsin preparation | cULus, CB | |

| Protection class | IP 40 | |

| Operation panel | ||

| LED | ON / OFF, FEED | |

| LCD graphics display Width x Height mm | 54 x 70 | |

| Control | ||

| Pre-warning to label web ending, broken liner, torque, temperature, voltage | ||

- Limitations can occur when processing small labels, thin materials or materials using a strong adhesive. Such applications require testing.

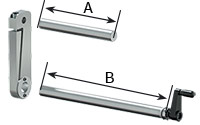

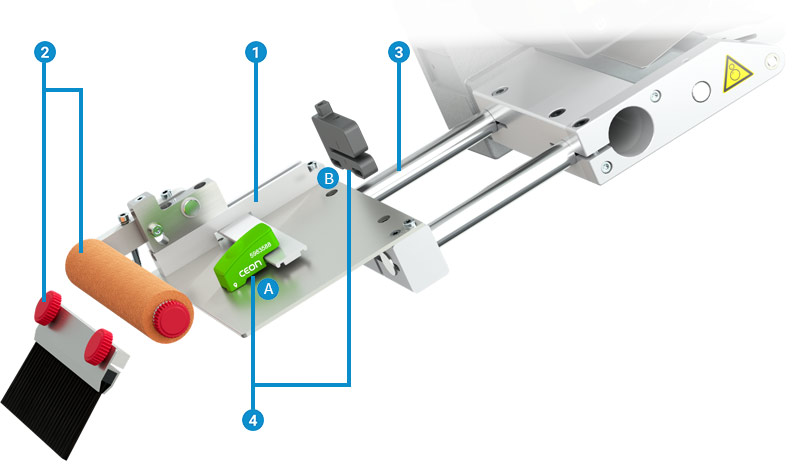

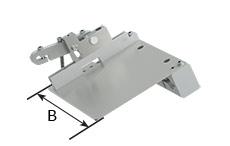

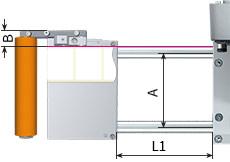

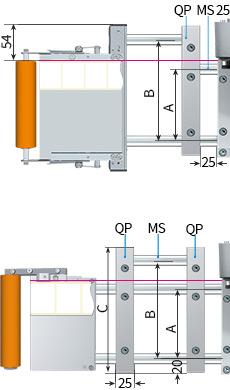

| Label dispenser | Dimension A mm | Dimension B mm | Weight kg |

|---|---|---|---|

| ROXI 120 | 124 | 145 | 12 |

| ROXI 180 | 186 | 205 | 13 |

| Demand module | Dimension C mm |

|---|---|

| SP | 19 |

| SPE | 24 |

| SPFA | 19 |

| Mounting rod | Dimension D mm |

|---|---|

| MS 25 | 25 |

| MS 100 | 100 |

| MS 200 | 200 |

| MS 300 | 300 |

| MS 400 | 400 |

Scopes of delivery, designs and technical data correspond to the date of this publication. They are subject to change. Catalogue data do not represent any warranty or guarantee.

For more technical data please read the product brochure (PDF)

Documentation

-

Catalogs

-

Title Format Version Last change Language ROXI

PDF - 2.78 MB 05/2025 15/05/2025 English

-

-

Assembly Instructions

-

Title Format Version Last change Language Assembly Instructions ROXI

PDF - 6.27 MB 04/2025 24/04/2025 English -

Other languages

-

Title Format Version Last change Language Montageanleitung ROXI

PDF - 6.35 MB 04/2025 24/04/2025 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List ROXI left

PDF - 936 KB 04/2025 06/05/2025 English Spare Parts List ROXI right

PDF - 933 KB 04/2025 06/05/2025 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste ROXI links

PDF - 946 KB 04/2025 06/05/2025 Deutsch Ersatzteilliste ROXI rechts

PDF - 945 KB 04/2025 06/05/2025 Deutsch

-

-

3D CAD models

The files are provided in STEP format, which requires CAD software. Follow this link to download a free STP Viewer: VariCAD Viewer (External website).

Select the desired model and click on the link. A short registration follows. cab will handle your personal information as described in our Privacy statement. This information will not be accessible to any third party for marketing purposes. You will receive an email with an activation link and you can download the models.

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Software & Drivers

-

Firmware

-

Title Format Version Last change Language Firmware ROXI

GZ - 58.21 MB 2.02 19/05/2025 – Release Notes Firmware ROXI

TXT - 851 bytes

TXT - 851 bytes

2.02 19/05/2025 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

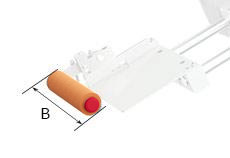

dispenser tongue, a

dispenser tongue, a  guide and an

guide and an  adjustable carriage. They are the same for all all types.

adjustable carriage. They are the same for all all types.

Label dispensers may be installed user-specific into production lines or labeling systems.

Label dispensers may be installed user-specific into production lines or labeling systems.