Tube labeling systems

AXON 1

Fast and reliable allocation of samples in labs with vertical tube/vial position

Labeling systems for tubes and vials

Unique labeling enables samples be assigned quick and reliably in labs. In practice, self-adhesive labels are applied individually to tubes or vials. 1D or 2D encoding enables samples be processed fully automated in transport and filing.

AXON has been designed for direct thermal and thermal transfer label printing. 300 dpi or 600 dpi print resolutions favor sharp-edge and high-contrast print images. The smallest codes and fonts can be verified reliably.

A labeling cycle takes less than two seconds. Tubes and vials with or without a closure cap can be inserted by hand or automated by a handling system.

Symbols on the control panel support AXON be operated intuitively. Replacing a label roll or a ribbon is no big deal. In cases of cleaning or wear, print rollers and transport rollers are easy to remove using a tool attached.

RS232, USB, Ethernet and WLAN ensure data be transferred. AXON integrates to Laboratory Information Management Systems (LIMS). If no PC is plugged, variable data can be entered on a control panel, with the help of a keyboard or a scanner. 110 VAC to 240 VAC input voltage at 50 / 60 Hz, 36 VDC to 60 VDC are options

Comparison of the tube labeling systems

AXON 1

| AXON 1 | AXON 2 | |

|---|---|---|

| Modules of a SQUIX 2P label printer and modules of the tube applicator are united in one chassis. | Printer | Standard SQUIX 4MP label printer providing an AXON 2 applicator |

| no more than 56 mm | Label widths | no more than 110 mm |

| vertical | Tube / vial orientation | horizontal |

| Once tubes or vials have been inserted to the retainer, they can be filled and sealed. | Particularity | Identified tubes and vials can be ejected automatically, for example to a tray. |

| 7 - 26 mm, a maximum of 38 mm may be possible upon request | Tube / vial diameters | 7 - 22 mm |

| 20 - 130 mm | Tube / vial lengths | 25 - 120 mm |

| Codes be verified | Option | - |

The control panel of our printers can be operated in over 30 languages

1 Ribbon retainer

Materials are easy to remove with the help of a three-part tightening axle.

2 Antistatic brush

Electrostatic charge dissipates after printing, in particular if plastic materials are in use.

3 Transport roller

Labels are applied to tubes or vials. Height setting according to the length of a tube or vial

4 Control panel

Intuitive operation using self-explanatory symbols Rotation in steps of 90° by software command

5 Internal liner rewind unit

Materials are easy to remove with the help of a three-part tightening axle.

6 Print roller

Synthetic rubber favors highly accurate print images.

7 Peel-off plate, extended

It promotes labels be applied reliably to tubes or vials.

8 Pinch roller

Tubes or vials are pressed against the transport roller as labels are applied.

36 VDC - 60 VDC input voltage

Instead of standard power supply, a 36 VDC to 60 VDC module can be installed. A mating plug is provided on delivery.

.jpg)

- AXON 1.2 processing labels 5 mm to 56 mm wide

9 Solid cast aluminum chassis

Base of all components

10 Base plate

Height setting enables labels be located accurately to target positions on tubes or vials.

- AXON 1.1 processing labels 5 mm to 25.4 mm wide. Small tubes or vials can be inserted more easily.

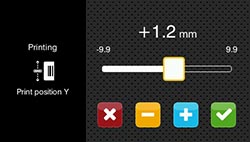

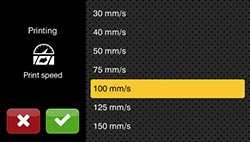

Control panel

Intuitive operation. Settings are easy to configure using self-explanatory symbols.

1 LED: Power ON

2 Status bar: Receive data, record datastream, warning on a ribbon ending, SD memory card / USB stick plugged, WLAN, Ethernet, USB slave, Time

3 Printer status: Ready, pause, number of labels printed on a print job,

label in peel-off position, awaiting external start signal

4 USB slot to plug a service key or a memory stick, to store data in the internal IFFS printer memory

5 Operation

Print and apply labels step by step

Print and apply labels step by step

Jump to menu

Jump to menu

Reprint the last label

Reprint the last label

Interrupt and continue a print job

Interrupt and continue a print job

Stop and delete all print jobs

Stop and delete all print jobs

Label feed

Label feed

Setup options

Print positions Y

Print parameters

Print speeds

AXON 1 tube labeling system

Landscape or portrait display depending on the orientation of assembly

Rotation in steps of 90° by software command

SQUIX label printer representing AXON 2

Video tutorials

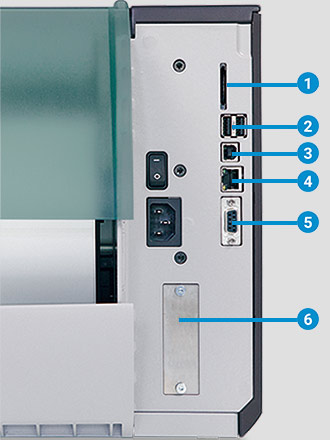

Interfaces

1 Slot to plug a SD memory card

2 2 USB hosts to plug a service key, a USB stick, a keyboard, a barcode scanner, an USB WLAN stick or an external control panel

3 USB 2.0 Hi-speed to plug a PC

4 Ethernet 10/100 Mbit/s

5 RS232C 1,200 to 230,400 Baud / 8 Bit

Options

6 Digital I/O interface; SUB-D socket connector, 25 pins

compliant with IEC/EN 61131-2, Type 1+3

Inputs and outputs are galvanically isolated and protect from reverse polarity. Outputs are short-circuit proof.

PNP inputs

Start printing / applying a label

Print initial label

Reprint

Delete print job

Label removed

Stop printing / applying a label

Label feed

Pause

Reset

PNP, NPN outputs

Device ready

Print data available

Initial position / upper end limit

Paper feed ON

Label in peel-off position

Labeling position / lower end limit

Warning on a ribbon ending

Ribbon / Label roll ending

Collective error

AXON 1 tube labeling system

SQUIX label printer representing AXON 2

The control panel of our printers can be operated in over 30 languages

typical

typical  standard

standard  option

option

| Tube labeling system | AXON 1.1 | AXON 1.2 | ||

|---|---|---|---|---|

| Print head | ||||

| Print method Thermal transfer |  |

|

|

|

| Print method Direct thermal |  |

- |  |

- |

| Print resolution dpi | 300 | 600 | 300 | 600 |

| Print speed mm/s | 100 | 100 | 100 | 100 |

| Print width mm max. | 25.4 | 25.4 | 56.9 | 54.1 |

| Print length mm max. | 12,000 | 3,000 | 12,000 | 3,000 |

| Material | ||||

| Tubes / Vials Orientation at the time of a label be applied | vertical | |||

| Tubes/Vials Diameter mm | 7 - 26, 16 - 38 if options are provided | |||

| Tubes/Vials Diametermm upon request max. | 38 | |||

| Tubes/Vials Length, closure cap included mm | 20 - 130 | |||

| Tubes/Vials Conicity (change in diameter) % max. | 0.8 | |||

| Labels1) Material | Paper, plastics such as PET, PP | |||

| Labels Width mm | 5 - 25.4 | 5 - 56 | ||

| Labels Height mm at least | 12 | |||

| Labels Thickness mm at least | 0.05 | |||

| Labels Roll diameter mm max. | 205 | |||

| Labels Core diameter mm | 76 | |||

| Labels Winding | outside | |||

| Liner Width mm | 16 - 30 | 24 - 60 | ||

| Liner Thickness2) mm | 0.045 - 0.05 | |||

| Ribbon Coating | outside or inside | |||

| Ribbon Roll diameter mm max. | 80 | |||

| Ribbon Core diameter mm | 25 | |||

| Ribbon Length m max. | 600 | |||

| Ribbon Width mm | 25 - 38.1 | 25 - 60 | ||

| Printer dimensions and weights | ||||

| Width x Height x Depth mm | 270 x 195 x 560 | |||

| Weight kg approx. | 12 | |||

| Label sensors / Position indicators | ||||

| Transmissive sensor to detect | labels or punch marks and materials ending, print marks on transparent materials | |||

| Reflective sensor bottom or top reflex to detect | labels and materials ending, print marks on non-transparent materials | |||

| Sensor distance to the contact edge left-aligned mm | 8 | 5 - 12 | ||

| Interfaces | ||||

| RS232-C 1,200 to 230,400 Baud / 8 Bit |  |

|||

| USB 2.0 Hi-speed to plug a PC |  |

|||

| Ethernet 10/100 Mbit/s | LPD, RawIP-Printing, SOAP-Webservice, OPC UA, WebDAV, DHCP, HTTP/HTTPS, FTP/FTPS, TIME, NTP, Zeroconf, SNMP, SMTP, VNC | |||

| 2 USB hosts on the control panel, 2 USB hosts on the back of a unit |

Service key, USB stick, USB WLAN stick, USB WLAN stick with a rod antenna, keyboard, barcode scanner, external control panel | |||

| Digital 24 VDC I/O interface |  |

|||

| Operational data | ||||

| Voltage 100 - 240 VAC, 50 / 60 Hz, PFC |  |

|||

| Voltage 36 - 60 VDC |  |

|||

| Power input | <10 W in standby / 80 W are typical / max. 200 W | |||

| Temperature / Humidity: In operation | +5 - 40 °C / 10 - 85 %, not condensing | |||

| Temperature / Humidity: On stock | 0 - 60 °C / 20 - 85 %, not condensing | |||

| Temperature / Humidity: In transport | –25 - 60 °C / 20 - 85 %, not condensing | |||

| Approvals | CE (in-vitro), UKCA, FCC Class A, ICES-3, cULus, CB further approvals upon request |

|||

| Control panel | ||||

| LCD color touchscreen diagonal “ | 4,3 | |||

| LCD color touchscreen Resolution - Width x Height px | 272 x 480 | |||

- Limitations may apply when using small labels, thin materials or strong adhesive. Critical applications need testing.

- Peeling labels off a liner requires liner materials not thicker than the labels.

Free and Open Source software are part of cab products. For information see www.cab.de/opensource

The control panel of our printers can be operated in over 30 languages

Cast aluminum cover

It prevents from contamination.

A large inspection window is provided.

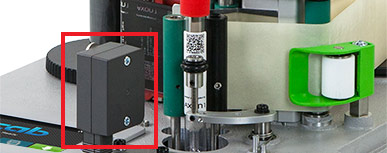

CC200-AXON code verifier

One 1D code* on a label can be checked on readability (GOODBAD) by a camera. One code per label can be verified in terms of readability. Results are compared with the print data (VERIFY).

*2D-Codes in preparation

K Type peel-off plate

customer-specific

If closure caps interfere with a peel-off plate, adaption is required.

Digital 24 VDC I/O interface

Digital 24 VDC I/O interface

SUB-D socket connector, 25 pins

Video: AXON 1 with robot - Labeling of tubes in medical industries

Powered by YouTube. See all cab videos: cab channel on YouTube.

cab shows in this study the universal labeling of different label formats and flexible labeling positions with a robot. Alternatively, the label printers are equipped with both the same label format and ensure continuous operation at media end.

Other format:

- AXON 1 with robot - Labeling of tubes in medical industries (MPEG-4; 162.2 MB)

Video: Tube labeling system AXON 1

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other format:

- Video: Tube labeling system AXON 1 (MPEG-4; 8 MB)

Documentation

-

Catalogs

-

Title Format Version Last change Language AXON 1 and AXON 2

PDF - 2.53 MB 07/2025 14/07/2025 English Overview Product Marking

PDF - 6.61 MB 07/2025 11/07/2025 English

-

-

Checklists

-

Title Format Version Last change Language Check list tube labeling systems AXON

PDF - 225 KB 04/2024 22/04/2024 English -

Other languages

-

Title Format Version Last change Language Checkliste Etikettiersystem AXON

PDF - 221 KB 04/2024 22/04/2024 Deutsch

-

-

-

Operation Manuals

-

Title Format Version Last change Language Instructions AXON 1

PDF - 2.50 MB 04/2024 13/06/2024 English -

Other languages

-

Title Format Version Last change Language Betriebsanleitung AXON 1

PDF - 2.53 MB 04/2024 13/06/2024 Deutsch Instructions d'utilisation AXON 1

PDF - 2.46 MB 04/2024 13/06/2024 Français

-

-

-

Interface Descriptions

-

Information on the interface type can be found on the original cab packaging, in the printer status report after installation or as a label next to the SUB-D connection.

Title Format Version Last change Language Interface Description I/O 24V25-2 and I/O 24V25-3

PDF - 278 KB 05/2025 16/05/2025 English Interface Description I/O 24V25-4

PDF - 278 KB 05/2025 16/05/2025 English -

Other languages

-

Title Format Version Last change Language Description de l'interface I/O 24V25-4

PDF - 301 KB 05/2025 16/05/2025 Français Description des interfaces I/O 24V25-2 et I/O 24V25-3

PDF - 302 KB 05/2025 16/05/2025 Français Schnittstellenbeschreibung I/O 24V25-2 und I/O 24V25-3

PDF - 265 KB 05/2025 16/05/2025 Deutsch Schnittstellenbeschreibung I/O 24V25-4

PDF - 268 KB 05/2025 16/05/2025 Deutsch

-

-

-

Programming

-

Title Format Version Last change Language Brief introduction to cab printer programming

PDF - 7.47 MB 04/2022 15/01/2025 English cab Download Converter (download.exe)

Converts image, font and database files into the JScript download data format.

Install MS Visual C++ 2010 Redistributable if not available on your system.ZIP - 9 KB 2.3 25/10/2024 – cabPROTECT - Data security in label printing

PDF - 472 KB 06/2024 20/06/2024 English Connecting cab printing systems to SAP®

CompendiumPDF - 4.45 MB 01/2025 11/02/2025 English Networked labeling with OPC UA

cab and the Smart FactoryPDF - 1.12 MB 03/2019 15/01/2025 English Programming Manual abc Basic Compiler

for cab printersPDF - 755 KB 11/2024 29/11/2024 English Programming Manual JScript

for SQUIX, MACH 4S, EOS2, EOS5, XC Q, XD Q, HERMES Q, PX Q, AXON1, AXON 2, A+, HERMES+, A-Series, EOS1/4, MACH4, XD, XCPDF - 4.30 MB 05/2025 23/05/2025 English ZPL Emulation with cab printers

PDF - 2.28 MB 05/2025 23/05/2025 English -

Other languages

-

Title Format Version Last change Language Anbindung von cab Drucksystemen an SAP®

KompendiumPDF - 4.55 MB 01/2025 11/02/2025 Deutsch cabPROTECT - Datensicherheit beim Etikettendruck

PDF - 475 KB 06/2024 20/06/2024 Deutsch Kurze Einführung in die cab Druckerprogrammierung

PDF - 7.50 MB 04/2022 12/04/2022 Deutsch Marquage en réseau avec OPC UA

cab et l'usine intelligentePDF - 745 KB 01/2022 23/10/2024 Français Vernetzt kennzeichnen mit OPC UA

cab und die intelligente FabrikPDF - 1.13 MB 03/2019 28/01/2021 Deutsch

-

-

-

Service Manuals

-

Title Format Version Last change Language Service Manual AXON 1

PDF - 4.69 MB 05/2025 20/05/2025 English -

Other languages

-

Title Format Version Last change Language Serviceanleitung AXON 1

PDF - 4.72 MB 05/2025 20/05/2025 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List AXON 1

PDF - 1.33 MB 07/2025 03/07/2025 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste AXON 1

PDF - 1.33 MB 07/2025 03/07/2025 Deutsch

-

-

-

Assembly Instructions Spare Parts

-

Title Format Version Last change Language 9004105 | Druckkopfwechsel / Printhead Replacement: SQUIX, HERMES Q, MACH 4S, EOS2, EOS5, PX Q, AXON1, XC Q, XD Q

PDF - 5.70 MB 06/2024 18/06/2024 English/Deutsch

-

-

Manuals Accessories

-

Title Format Version Last change Language External Operation Panel - Instructions

PDF - 274 KB 04/2023 12/04/2023 English Label File Selection Box - Input Output Box - Instructions

PDF - 329 KB 04/2023 12/04/2023 English -

Other languages

-

Title Format Version Last change Language Externes Bedienfeld - Betriebsanleitung

PDF - 280 KB 04/2023 12/04/2023 Deutsch Panneau de commande externe - Instructions d'utilisation

PDF - 277 KB 04/2023 12/04/2023 Français

-

-

-

EU Declarations of Conformity - Accessories

-

Title Format Version Last change Language External Operation Panel - EU Declaration of Conformity

PDF - 30 KB 07/2019 02/02/2023 English Label File Selection Box - I/O Box - EU Declaration of Conformity

PDF - 30 KB 07/2019 02/02/2023 English -

Other languages

-

Title Format Version Last change Language Etikettenauswahlbox - Ein-/Ausgabebox - Konformitätserklärung

PDF - 30 KB 07/2019 02/12/2020 Deutsch Externes Bedienfeld - Konformitätserklärung

PDF - 30 KB 07/2019 02/12/2020 Deutsch Labelbox - I/O Box - Déclaration UE de conformité

PDF - 30 KB 07/2019 02/12/2020 Français Panneau de commande externe - Déclaration UE de conformité

PDF - 30 KB 07/2019 02/12/2020 Français

-

-

-

Case study

-

Title Format Version Last change Language HTI, specialist in lab and manufacture automation: Opening, filling and labeling micro-screw tubes

PDF - 650 KB 11/2022 16/11/2022 English

-

-

Safety data sheets

-

Title Format Version Last change Language Safety Data Sheet Special Cleaner for Glass and Plastic GR1N

PDF - 65 KB 08/2017 23/10/2024 English -

Other languages

-

Title Format Version Last change Language Sicherheitsdatenblatt Spezial Glasreiniger und Kunststoffreiniger GR1N

PDF - 156 KB 06/2017 25/08/2022 Deutsch Sicherheitsdatenblatt Spezial-Gummiwalzen-Reiniger WR1

PDF - 173 KB 06/2017 25/08/2022 Deutsch

-

-

3D CAD models

The files are provided in STEP format, which requires CAD software. Follow this link to download a free STP Viewer: VariCAD Viewer (External website).

Select the desired model and click on the link. A short registration follows. cab will handle your personal information as described in our Privacy statement. This information will not be accessible to any third party for marketing purposes. You will receive an email with an activation link and you can download the models.

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Here you can download firmware, drivers and software. Documentation on label software, printers programming and administration as well as integration of cab printers into SAP systems:

Label software

Software & Drivers

-

Firmware

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Firmware X4

Firmware SQUIX | EOS2 | EOS5 | MACH 4S | XD Q | XC Q | HERMES Q | PX Q | AXONZIP - 53.66 MB 5.46.4 05/06/2025 – Release Notes Firmware X4

TXT - 123 KB

TXT - 123 KB

5.00 - 5.46.4 05/06/2025 –

-

-

Firmware periphery

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Firmware AXON 1

ZIP - 56 KB 1.1.0 28/01/2025 – Firmware I/O 24V25-2, I/O 24V25-3, I/O 5V15-2 and I/O 5V15-3

ZIP - 23 KB 3.2.0 08/04/2025 –

-

-

Drivers

-

Title Format Version Last change Language cab Linux Armv7 - 32 Bit Driver

CUPS Linux Armv7 32bit Driver RPi 2/3/4 (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab Linux Armv8(aarch64) - 64 Bit Driver

CUPS Linux Armv8 64 Bit Driver RPi 3/4 (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab Linux x86 - 32 Bit Driver

CUPS Linux Intel 32bit Driver (min. CUPS 1.2)GZ - 2.81 MB 1.46 23/10/2024 – cab Linux x86 - 64 Bit Driver

CUPS Linux Intel/AMD 64bit Driver (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab MAC OS Driver

Apple® Mac OS 10.15 - 15.4ZIP - 2.97 MB 1.46 01/04/2025 – cab MAC OS X Driver

Apple® Mac OS X 10.6 - 10.14ZIP - 5.82 MB 1.46 23/10/2024 – cab Windows Driver NEW

Windows 10, Windows 11, Windows Server 2016, Windows Server 2019, Windows Server 2022 - 64Bit, requires Visual C++ 2022ZIP - 24.01 MB 1.4.1.0 24/03/2025 – cab Windows Driver NEW Release Notes

PDF - 120 KB 1.2.1.20 - 1.4.1.0 24/03/2025 –

-

-

Software

-

Title Format Version Last change Language cab Download Converter (download.exe)

Converts image, font and database files into the JScript download data format.

Install MS Visual C++ 2010 Redistributable if not available on your system.ZIP - 9 KB 2.3 25/10/2024 – cablabel S3 Demo (Free)

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 51.42 MB 1.4.0.10 11/07/2025 – cablabel S3 Lite (Free)

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 69.78 MB 1.4.0.10 11/07/2025 – cablabel S3 Print

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 75.95 MB 1.4.0.10 11/07/2025 – cablabel S3 Pro

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 86.77 MB 1.4.0.10 11/07/2025 – Database Connector

Windows 32 & 64 bitZIP - 10.93 MB 4.3.0.1 25/10/2024 – LogService

for Database ConnectorZIP - 4.15 MB 1.7.1.0 25/10/2024 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader