Label printer

XD Q

for printing on both sides of a material

Highlights

- Print resolution 300 dpi if printing as wide as 105.7 mm

Print resolution 600 dpi if printing no more than 54.1 mm wide using a DR4-M60 print roller

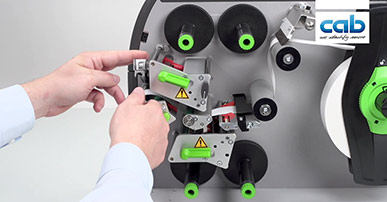

Print heads designed for 300 dpi and such for 600 dpi are not interchangeable on the unit. - Heating can be assigned separately to each print head.

- If printing only on the top of a material using print head 2, print head 1 is automatically lifted and the ribbon is stopped by an electromechanical brake.

- Guiding materials in centered position results in precise print images in particular with slim continuous materials are in use. The width of a material is set with the help of a spindle.

- Automated ribbon saving is provided on print head 1 when printing on the bottom of a material. The print head is lifted and the ribbon is stopped during material feed.

- Continuous print images when cutting or perforating labels at no backfeed.

- Optimized printing, so that multiple print jobs can be printed seamless and without loss of labels.

- CSQ cutters and PSQ perforation cutters

- A separator is part of the chassis. It separates continuous material reliably from a ribbon and improves the accuracy of feeding.

Type of transport roller:

Steel is a standard if printing on textile materials.

Rubber is an option with shrink tubes.

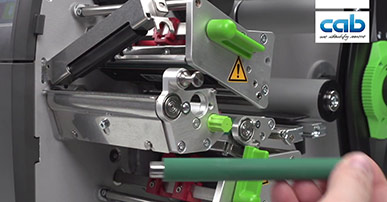

A transport roller can be pivoted for material changeover. - Find documentation on the Internet. DVDs are no longer part of delivery.

Textile tapes

Cardboard labels

Identification strips

Cable marking

Shrink tubes continuous or ready for use

Labels

Printing only on the top of a material using print head 2

Types of printers

1.1 XD Q providing a tear-off plate

All materials wound on a roll or a reel can be printed,

so can fanfold ones.

| Label printer | XD Q4/300 | XD Q4.2/600 |

|---|---|---|

| Print resolution dpi | 300 | 600 |

| Print speed mm/s max. | 150 | 100 |

| Print width mm max. | 105.7 | 54.1 |

| Width of a material mm max. | 114 | 114 |

1.2 XD Q providing an UHF RFID module with read / write antennas

1.2 XD Q providing an UHF RFID module with read / write antennas

The module is installed into the chassis, the antenna directly on the print head. RFID tags are read and written just before the labels are printed. In the event of errors, labels are indicated invalid.

provided upon request

Video: Label printer XD Q - ST400 M stacker providing a cutter

for printing on both sides of a material, cutting and stacking labels

SOTI Connect software enables label printers be configured and managed centrally.

The control panel of our printers can be operated in over 30 languages

typical

typical  standard

standard  option

option

| Label printer | XD Q4/300 | XD Q4.2/600 |

|---|---|---|

| Guidance of materials | centered | centered |

| Print method Thermal transfer |  |

|

| Print resolution dpi | 300 | 600 |

| Print speed mm/s max. | 150 | 100 |

| Print width mm max. | 105.7 | 54.1 |

| Print length mm max. | 3,000 | 1,500 |

| Automated ribbon saving |  |

|

| Materials1) | ||

| Paper, cardboard, synthetics PET, PE, PP, PI, PVC, PU, acrylate, Tyvec |  |

|

| Shrink tube ready for use |  |

|

| Shrink tube continuous, pressed |  |

|

| Textile tape |  |

|

| Finishing Roll, fanfold |  |

|

| Finishing Roll diameter mm max. | 300 | |

| Finishing Core diameter mm | 38.1 - 76 | |

| Finishing Winding | outside or inside | |

| Label Width mm | 10 - 110 | |

| Label Height mm at least | 20 | |

| Label Thickness mm max. | 0.1 | |

| Liner Width mm | 14 - 114 | |

| Liner Thickness mm | 0.03 - 0.16 | |

| Continuous Width mm | 4 - 114 | |

| Continuous Thickness mm | 0.03 - 0.5 | |

| Continuous Weight (cardboard) g/m2 max. | 300 | |

| Shrink tube Width ready for use mm max. | 114 | |

| Shrink tube Width continuous, pressed mm | 4 - 85 | |

| Shrink tube Thickness mm max. | 1.1 | |

| Ribbon2) Color layer | outside or inside | |

| Ribbon Roll diameter mm max. | 80 | |

| Ribbon Core diameter mm | 25.4 | |

| Ribbon Length m max. | 450 | |

| Ribbon Width mm max. | 114 | |

| Printer dimensions, weight | ||

| Width x height x depth mm | 248 x 395 x 594 | |

| Weight kg | 21 | |

| Label sensors, position indicators | ||

| Transmissive sensor detecting | labels, punch marks, materials ending, print marks on translucent materials | |

| Reflective sensor from below or top detecting | labels, materials ending, print marks on non-translucent materials | |

| Sensor distance centre to locating edge centered mm | 0 - 55 | |

| Material passage mm max. | 2 | |

| Electronics | ||

| Processor, 32 bit clock rateMHz | 800 | |

| RAMMB | 256 | |

| IFFSMB | 50 | |

| Port for plugging a SD memory card (SDHC, SDXC)GB max. | 512 | |

| Battery for indicating time and date, real-time clock |  |

|

| Data kept in memory (e.g. serial numbers) when power turns off |  |

|

| Interfaces | ||

| RS232-C 1,200 to 230,400 baud / 8 bit |  |

|

| USB 2.0 Hi-Speed device to plug a PC |  |

|

| Ethernet 10/100 Mbit/s IPv4 and IPv6 |

LPD, RawIP printing, SOAP web service, OPC UA, WebDAV, DHCP, HTTP/HTTPS, FTP/FTPS, TIME, NTP, Zeroconf, SNMP, SMTP, VNC | |

| 2 USB hosts on the control panel, 2 USB hosts on the back of a unit |

Service key, USB stick, USB WLAN stick, USB WLAN stick with a rod antenna, keyboard, barcode scanner, external control panel | |

| USB host, 24 VDC, to plug peripherals |  |

|

| Digital I/O interface providing 8 inputs and 8 outputs |  |

|

| Operating data | ||

| Voltage | 100 - 240 VAC, 50/60 Hz, PFC | |

| Consumption of power | < 15 W in standby / 100 W in typical operation / max. 200 W | |

| Temperature / humidity Operation | +5 - 40°C / 10 - 85 %, not condensing | |

| Temperature / humidity Stock | 0 - 60°C / 20 - 85 %, not condensing | |

| Temperature / humidity Transport | –25 - 60°C / 20 - 85 %, not condensing | |

| Approvals | CE, UKCA, FCC Class A, ICES-3, cULus, CB, CCC, BIS, BSMI, KC-Mark, Mexico Reg. | |

| Control panel | ||

| Color LCD touchscreen Diagonal" | 4.3 | |

| Color LCD touchscreen Resolution Width x Height px | 272 x 480 | |

For more technical data please read the product brochure (PDF)

- Specifications are standards. Operations including small, slim, thick or stiff materials need testing, so do strongly adhesive labels.

- A ribbon should be at least as wide as the liner material.

SOTI Connect software enables label printers be configured and managed centrally.

The control panel of our printers can be operated in over 30 languages

Accessories / optional equipment

Accessorial products are plugged or screwed to a printer by a customer.

Options are parts or units to perform special functions. They are assembled to a printer in addition to or instead of standards. If order implies options be assembled ex factory, corresponding item numbers are added by .250.

Options delivered separately are added by .001.

Adapter 40/100

for picking up label rolls with a core diameter of 100 mm

One adapter is sufficient if processing materials no more than 50 mm wide.

Digital I/O interface

Labeling is triggered via a PLC, a sensor or a hand switch. Status reports and errors are displayed simultaneously.

Slim print rollers

They allow for accurate print results with small materials and ribbons.

Synthetic rubber material for highly a ccurate print images

Type

DR4-M30

DR4-M60

DR4-M80

materials as wide as

30 mm

60 mm

80 mm

Silicone material

preferred for textile operations and for extralong lifecycles

DRS4-M35

DRS4-M50

35 mm

50 mm

Standard print rollers

Type: materials as wide as 120 mm

DR4: Synthetic rubber

DRS4: Silicone

Transport rollers for separators

Type materials as wide as 120 mm

TR4: 120 mm (synthetic rubber) preferred for shrink tube operations

TR4-M60: 60 mm preferred for textile operations

Documentation

-

Catalogs

-

Title Format Version Last change Language Label printer XD Q

PDF - 2.96 MB 03/2025 25/03/2025 English Labeling cables

PDF - 1.38 MB 06/2024 12/12/2024 English Overview Product Marking

PDF - 6.61 MB 07/2025 11/07/2025 English UHF RFID label printers

PX Q | HERMES Q | XD Q | SQUIXPDF - 860 KB 03/2025 18/03/2025 English

-

-

Operation Manuals

-

Title Format Version Last change Language Instructions XD Q

PDF - 4.01 MB 05/2025 22/05/2025 English -

Other languages

-

Title Format Version Last change Language Betriebsanleitung XD Q

PDF - 4.51 MB 05/2025 22/05/2025 Deutsch Bruksanvisning XD Q

PDF - 4.48 MB 05/2025 22/05/2025 Norsk Bruksanvisning XD Q

PDF - 4.48 MB 05/2025 22/05/2025 Svensk Driftsvejledning XD Q

PDF - 4.48 MB 05/2025 22/05/2025 Dansk Gebruiksaanwijzing XD Q

PDF - 4.48 MB 05/2025 22/05/2025 Nederlands Instrucciones XD Q

PDF - 4.51 MB 05/2025 22/05/2025 Español Instructions d'utilisation XD Q

PDF - 4.03 MB 05/2025 22/05/2025 Français Instrucțiuni de utilizare XD Q

PDF - 4.53 MB 05/2025 22/05/2025 Română Instrukcja obsługi XD Q

PDF - 4.53 MB 05/2025 22/05/2025 Polski İşletim Kılavuzu XD Q

PDF - 4.53 MB 05/2025 22/05/2025 Türkçe Istruzioni per l'uso XD Q

PDF - 4.50 MB 05/2025 22/05/2025 Italiano Kasutusjuhend XD Q

PDF - 4.48 MB 05/2025 22/05/2025 Eesti Käyttöohje XD Q

PDF - 4.48 MB 05/2025 22/05/2025 Suomi Lietošanas pamācība XD Q

PDF - 4.53 MB 05/2025 22/05/2025 Latviešu Manual de instruções XD Q

PDF - 4.52 MB 05/2025 22/05/2025 Português Naudojimo instrukcija XD Q

PDF - 4.53 MB 05/2025 22/05/2025 Lietuvių Návod k obsluze XD Q

PDF - 4.53 MB 05/2025 22/05/2025 Čeština Návod na obsluhu XD Q

PDF - 4.53 MB 05/2025 22/05/2025 Slovenský Navodila za uporabo XD Q

PDF - 4.51 MB 05/2025 22/05/2025 Slovenščina Upute za uporabu XD Q

PDF - 4.52 MB 05/2025 22/05/2025 Hrvatski Uputstvo za upotrebu XD Q

PDF - 4.52 MB 05/2025 22/05/2025 Srpski Üzemeltetési útmutató XD Q

PDF - 4.52 MB 05/2025 22/05/2025 Magyar Οδηγίες λειτουργίας XD Q

PDF - 4.56 MB 05/2025 22/05/2025 ελληνικά Инструкция за експлоатация XD Q

PDF - 4.56 MB 05/2025 22/05/2025 Български Руководство по эксплуатации XD Q

PDF - 4.58 MB 05/2025 22/05/2025 Pусский Упатство за употреба XD Q

PDF - 4.56 MB 05/2025 22/05/2025 Македонски คู่มือการใช้งาน XD Q

PDF - 4.59 MB 05/2025 22/05/2025 ภาษาไทย 使用說明書 XD Q

PDF - 5.25 MB 05/2025 22/05/2025 繁體字 使用说明书 XD Q

PDF - 5.05 MB 05/2025 22/05/2025 简体字 取扱説明書 XD Q

PDF - 5.06 MB 05/2025 22/05/2025 日本語 사용 설명서 XD Q

PDF - 4.79 MB 05/2025 22/05/2025 한국어

-

-

-

EU Declaration of Conformity

-

Title Format Version Last change Language EU Declaration of Conformity XD Q

PDF - 72 KB 09/2022 13/09/2022 English EU Declaration of Conformity XD Q

PDF - 72 KB 09/2022 07/02/2023 English -

Other languages

-

Title Format Version Last change Language AB-Uyumluluk Bildirimi XD Q

PDF - 72 KB 09/2022 24/04/2023 Türkçe Declaração UE de conformidade XD Q

PDF - 73 KB 09/2022 24/04/2023 Português Declaraţie de conformitate UE XD Q

PDF - 71 KB 09/2022 24/04/2023 Română Deklaracja zgodności UE XD Q

PDF - 72 KB 09/2022 24/04/2023 Polski ELi vastavusdeklaratsioon XD Q

PDF - 69 KB 09/2022 24/04/2023 Eesti ES atbilstības deklarācija XD Q

PDF - 72 KB 09/2022 24/04/2023 Latviešu ES atitikties deklaracija XD Q

PDF - 72 KB 09/2022 24/04/2023 Lietuvių EU izjava o sukladnosti XD Q

PDF - 70 KB 09/2022 24/04/2023 Hrvatski EU prohlášení o shodě XD Q

PDF - 72 KB 09/2022 24/04/2023 Čeština EÚ vyhlásenie o zhode XD Q

PDF - 72 KB 09/2022 24/04/2023 Slovenský EU-conformiteitsverklaring XD Q

PDF - 72 KB 09/2022 24/04/2023 Nederlands EU-försäkran om överensstämmelse XD Q

PDF - 70 KB 09/2022 24/04/2023 Svensk EU-Konformitätserklärung XD Q

PDF - 73 KB 09/2022 13/09/2022 Deutsch EU-megfelelőségi nyilatkozat XD Q

PDF - 72 KB 09/2022 24/04/2023 Magyar EU-overensstemmelseserklæring XD Q

PDF - 72 KB 09/2022 24/04/2023 Dansk EU-samsvarserklæring XD Q

PDF - 72 KB 09/2022 24/04/2023 Norsk EU-vaatimustenmukaisuusvakuutus XD Q

PDF - 70 KB 09/2022 24/04/2023 Suomi Izjava EU o skladnosti XD Q

PDF - 70 KB 09/2022 24/04/2023 Slovenščina Δήλωση συμμόρφωσης ΕΕ XD Q

PDF - 90 KB 09/2022 24/04/2023 ελληνικά Декларација за сообразност на ЕУ XD Q

PDF - 122 KB 09/2022 24/04/2023 Македонски Декларация соответствия требованиям ЕС XD Q

PDF - 79 KB 09/2022 24/04/2023 Pусский ЕU-Izjava o usaglašenosti XD Q

PDF - 143 KB 09/2022 24/04/2023 Srpski ЕС декларация за съответствие XD Q

PDF - 77 KB 09/2022 24/04/2023 Български

-

-

-

UKCA Declaration of Conformity

-

Title Format Version Last change Language UKCA Declaration of Conformity XD Q

PDF - 71 KB 04/23 24/04/2023 English

-

-

Interface Descriptions

-

Information on the interface type can be found on the original cab packaging, in the printer status report after installation or as a label next to the SUB-D connection.

Title Format Version Last change Language Interface Description I/O 24V25-4

PDF - 278 KB 05/2025 16/05/2025 English Interface Description I/O 24V25-1

PDF - 334 KB 05/2020 06/02/2024 English Interface Description I/O 24V25-2 and I/O 24V25-3

PDF - 278 KB 05/2025 16/05/2025 English -

Other languages

-

Title Format Version Last change Language Description de l'interface I/O 24V25-4

PDF - 301 KB 05/2025 16/05/2025 Français Description des interfaces I/O 24V25-2 et I/O 24V25-3

PDF - 302 KB 05/2025 16/05/2025 Français Schnittstellenbeschreibung I/O 24V25-1

PDF - 324 KB 05/2020 01/03/2023 Deutsch Schnittstellenbeschreibung I/O 24V25-2 und I/O 24V25-3

PDF - 265 KB 05/2025 16/05/2025 Deutsch Schnittstellenbeschreibung I/O 24V25-4

PDF - 268 KB 05/2025 16/05/2025 Deutsch

-

-

-

Configuration Manuals

-

Title Format Version Last change Language Configuration manual cab Label Printers

from SN 14089PDF - 2.57 MB 08/2024 19/08/2024 English -

Other languages

-

Title Format Version Last change Language Konfigurationsanleitung cab-Etikettendrucker

ab SN 14089PDF - 2.60 MB 08/2024 19/08/2024 Deutsch Manuel de configuration imprimantes d'étiquettes cab

à partir du numéro de série 0014089PDF - 2.66 MB 08/2024 19/08/2024 Français

-

-

-

Programming

-

Title Format Version Last change Language Brief introduction to cab printer programming

PDF - 7.47 MB 04/2022 15/01/2025 English cab Download Converter (download.exe)

Converts image, font and database files into the JScript download data format.

Install MS Visual C++ 2010 Redistributable if not available on your system.ZIP - 9 KB 2.3 25/10/2024 – cabPROTECT - Data security in label printing

PDF - 472 KB 06/2024 20/06/2024 English Connecting cab printing systems to SAP®

CompendiumPDF - 4.45 MB 01/2025 11/02/2025 English Networked labeling with OPC UA

cab and the Smart FactoryPDF - 1.12 MB 03/2019 15/01/2025 English PLC Programmer's Guide HERMES Q, SQUIX, XD Q, PX Q

with label layouts and programming examplesZIP - 16.17 MB 06/2020 15/01/2025 English Programming Manual abc Basic Compiler

for cab printersPDF - 755 KB 11/2024 29/11/2024 English Programming Manual JScript

for SQUIX, MACH 4S, EOS2, EOS5, XC Q, XD Q, HERMES Q, PX Q, AXON1, AXON 2, A+, HERMES+, A-Series, EOS1/4, MACH4, XD, XCPDF - 4.30 MB 05/2025 23/05/2025 English ZPL Emulation with cab printers

PDF - 2.28 MB 05/2025 23/05/2025 English -

Other languages

-

Title Format Version Last change Language Anbindung von cab Drucksystemen an SAP®

KompendiumPDF - 4.55 MB 01/2025 11/02/2025 Deutsch cabPROTECT - Datensicherheit beim Etikettendruck

PDF - 475 KB 06/2024 20/06/2024 Deutsch Kurze Einführung in die cab Druckerprogrammierung

PDF - 7.50 MB 04/2022 12/04/2022 Deutsch Marquage en réseau avec OPC UA

cab et l'usine intelligentePDF - 745 KB 01/2022 23/10/2024 Français SPS Programmieranleitung HERMES Q, SQUIX, XD Q, PX Q

mit Etikettenlayouts und BeispielprogrammenZIP - 16.22 MB 06/2020 18/04/2024 Deutsch Vernetzt kennzeichnen mit OPC UA

cab und die intelligente FabrikPDF - 1.13 MB 03/2019 28/01/2021 Deutsch

-

-

-

Service Manuals

-

Title Format Version Last change Language Service Manual XD Q

PDF - 3.76 MB 05/2025 20/05/2025 English -

Other languages

-

Title Format Version Last change Language Serviceanleitung XD Q

PDF - 3.75 MB 05/2025 20/05/2025 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List XD Q

PDF - 1.58 MB 02/2025 12/02/2025 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste XD Q

PDF - 1.58 MB 02/2025 12/02/2025 Deutsch

-

-

-

Assembly Instructions Spare Parts

-

Title Format Version Last change Language 9004105 | Druckkopfwechsel / Printhead Replacement: SQUIX, HERMES Q, MACH 4S, EOS2, EOS5, PX Q, AXON1, XC Q, XD Q

PDF - 5.70 MB 06/2024 18/06/2024 English/Deutsch

-

-

cab Video Tutorials

-

Title Format Version Last change Language Video tutorial: How to clean the print roller of XD Q?

– – 27/06/2025 – Video tutorial: How to clean the printhead of XD Q?

– – 27/06/2025 – Video tutorial: How to load labels in the XD Q?

– – 27/06/2025 – Video tutorial: How to load ribbon in the XD Q?

– – 27/06/2025 –

-

-

Feed Path Schemes

-

Title Format Version Last change Language Feed path scheme XD Q with antistatic brush

for inside and outside wound ribbon in dual dashed linesPDF - 230 KB 08/2024 09/08/2024 – Feed path scheme XD Q without antistatic brush

for inside and outside wound ribbon in dual dashed linesPDF - 226 KB 08/2024 09/08/2024 –

-

-

Manuals Accessories

-

Title Format Version Last change Language Cutter CSQ401 / CSQ402 - Instructions

PDF - 1.63 MB 04/2023 12/04/2023 English Cutter CU200 / CU400 / CU600 / CU800 - Instructions

PDF - 880 KB 04/2023 06/04/2023 English External Operation Panel - Instructions

PDF - 274 KB 04/2023 12/04/2023 English Label File Selection Box - Input Output Box - Instructions

PDF - 329 KB 04/2023 12/04/2023 English Perforation Cutter PCU400 - Instructions

PDF - 881 KB 04/2023 06/04/2023 English Perforation Cutter PSQ403 - Instructions

PDF - 1.65 MB 04/2023 12/04/2023 English Stacker with Cutter ST400 - Instructions

PDF - 1.13 MB 04/2023 12/04/2023 English -

Other languages

-

-

Spare Parts Accessories

-

Title Format Version Last change Language Cutter CSQ 401 / CSQ 402 - Spare Parts List

PDF - 241 KB 01/2025 30/01/2025 English Cutter CU200 / CU400 / CU600 / CU800 - Spare Parts List

PDF - 228 KB 09/2022 06/02/2023 English Perforation Cutter PCU400 - Spare Parts List

PDF - 281 KB 10/2018 06/02/2023 English Perforation Cutter PSQ 403 - Spare Parts List

PDF - 283 KB 01/2025 30/01/2025 English Stacker with Cutter ST400 - Spare Parts List

PDF - 502 KB 10/2018 06/02/2023 English -

Other languages

-

Title Format Version Last change Language Perforationsmesser PCU400 - Ersatzteilliste

PDF - 300 KB 10/2018 03/12/2020 Deutsch Perforationsmesser PSQ 403 - Ersatzteilliste

PDF - 286 KB 01/2025 30/01/2025 Deutsch Schneidemesser CSQ 401 / CSQ 402 - Ersatzteilliste

PDF - 244 KB 01/2025 30/01/2025 Deutsch Schneidemesser CU200 / CU400 / CU600 / CU800 - Ersatzteilliste

PDF - 231 KB 09/2022 13/09/2022 Deutsch Stapler mit Schneidemesser ST400 - Ersatzteilliste

PDF - 505 KB 10/2018 03/12/2020 Deutsch

-

-

-

Safety data sheets

-

Title Format Version Last change Language Safety Data Sheet Special Cleaner for Glass and Plastic GR1N

PDF - 65 KB 08/2017 23/10/2024 English Safety Data Sheet Special Rubber Cleaner WR1

PDF - 76 KB 12/2017 23/10/2024 English -

Other languages

-

Title Format Version Last change Language Sicherheitsdatenblatt Spezial Glasreiniger und Kunststoffreiniger GR1N

PDF - 156 KB 06/2017 25/08/2022 Deutsch Sicherheitsdatenblatt Spezial-Gummiwalzen-Reiniger WR1

PDF - 173 KB 06/2017 25/08/2022 Deutsch

-

-

3D CAD models

The files are provided in STEP format, which requires CAD software. Follow this link to download a free STP Viewer: VariCAD Viewer (External website).

Select the desired model and click on the link. A short registration follows. cab will handle your personal information as described in our Privacy statement. This information will not be accessible to any third party for marketing purposes. You will receive an email with an activation link and you can download the models.

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Software & Drivers

-

Firmware

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Firmware X4

Firmware SQUIX | EOS2 | EOS5 | MACH 4S | XD Q | XC Q | HERMES Q | PX Q | AXONZIP - 53.66 MB 5.46.4 05/06/2025 – Release Notes Firmware X4

TXT - 123 KB

TXT - 123 KB

5.00 - 5.46.4 05/06/2025 –

-

-

Firmware periphery

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Firmware CSQ 401, CSQ 402, PSQ 403, PSQ404

ZIP - 59 KB 3.12.0 08/04/2025 – Firmware I/O 24V25-2, I/O 24V25-3, I/O 5V15-2 and I/O 5V15-3

ZIP - 23 KB 3.2.0 08/04/2025 –

-

-

Drivers

-

Title Format Version Last change Language cab Linux Armv7 - 32 Bit Driver

CUPS Linux Armv7 32bit Driver RPi 2/3/4 (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab Linux Armv8(aarch64) - 64 Bit Driver

CUPS Linux Armv8 64 Bit Driver RPi 3/4 (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab Linux x86 - 32 Bit Driver

CUPS Linux Intel 32bit Driver (min. CUPS 1.2)GZ - 2.81 MB 1.46 23/10/2024 – cab Linux x86 - 64 Bit Driver

CUPS Linux Intel/AMD 64bit Driver (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab MAC OS Driver

Apple® Mac OS 10.15 - 15.4ZIP - 2.97 MB 1.46 01/04/2025 – cab MAC OS X Driver

Apple® Mac OS X 10.6 - 10.14ZIP - 5.82 MB 1.46 23/10/2024 – cab Windows Driver NEW

Windows 10, Windows 11, Windows Server 2016, Windows Server 2019, Windows Server 2022 - 64Bit, requires Visual C++ 2022ZIP - 24.01 MB 1.4.1.0 24/03/2025 – cab Windows Driver NEW Release Notes

PDF - 120 KB 1.2.1.20 - 1.4.1.0 24/03/2025 –

-

-

Software

-

Title Format Version Last change Language cab Download Converter (download.exe)

Converts image, font and database files into the JScript download data format.

Install MS Visual C++ 2010 Redistributable if not available on your system.ZIP - 9 KB 2.3 25/10/2024 – cablabel S3 Demo (Free)

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 51.42 MB 1.4.0.10 11/07/2025 – cablabel S3 Lite (Free)

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 69.78 MB 1.4.0.10 11/07/2025 – cablabel S3 Print

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 75.95 MB 1.4.0.10 11/07/2025 – cablabel S3 Pro

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 86.77 MB 1.4.0.10 11/07/2025 – Database Connector

Windows 32 & 64 bitZIP - 10.93 MB 4.3.0.1 25/10/2024 – LogService

for Database ConnectorZIP - 4.15 MB 1.7.1.0 25/10/2024 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

The table and the protective cover are adapted to the size of a label. Please request individually.

The table and the protective cover are adapted to the size of a label. Please request individually.