Laser marking system

XENO 1

Compact desktop system, offering little footprint and a large work area

Never has laser marking been so easy! Unpack the device, install the software, connect and get started.

XENO 1 is a compact desktop system, offering little footprint and a large work area.

XENO 1 perfectly fits with marking on metals or plastics.

XENO 1 completes the range of cab laser marking systems in the lower price segment. Processing the system complies with high industrial standards.

The marking plane is easily and quickly adjustable in height up to 200 mm with the motor-driven moveable Z-axis and the focus finder. In case of different height levels at the workpiece, the scan head can be automatically adjusted to the right focus distance by the integrated numeric Z-axis.

The marking can be simulated with the pilot laser. Interior LED lighting allows observation of the workpiece when the operation door is closed. The workpiece holder is mounted on the groove plate. A rotary axis is available for cylindrical objects. The focus finder makes it easy to adjust the marking plane.

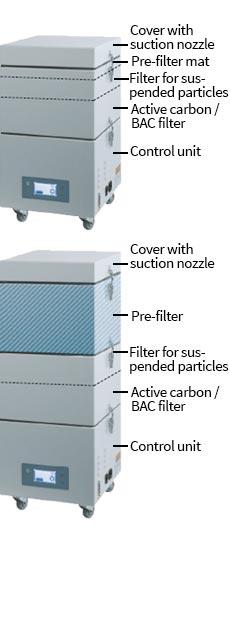

The automatic operation door opens or closes within seconds. Material can be inserted manually or by a handling system from three sides. The extraction and filter system extracts pollutant particles, dusts or gaseous pollutants. It is provided as an accessory.

With the comprehensive cabLase marking software layouts are graphically designed, markings controlled and processes monitored. The legal environmental regulations RoHS and REACH are observed.

Video: XENO 1 compact all-in-one laser marking system

Never has laser marking been so easy! Sales director Mario Hiss highlights the benefits of XENO 1.

Sample applications

Engraving

Engraving

Evaporation with high energy density removes the material. An indentation with a sharp outline occurs.

Annealing

Annealing

is mainly applied with highly alloyed stainless steel as well as with titanium.

Ablating

Ablating

The laser ablates the top layer to uncover the underneath material. Examples include anodized layers or paint coatings.

Coloring

Coloring

is applied with plastics. The way the color changes depends from the chemical composition of the material as well as from ingredients and fillers.

Foaming

Foaming

The laser melts into the surface of the material.

Opening, filling and labeling micro-screw tubes.

XENO 1 is a fully equipped laser marking system offering high operating comfort for marking single components and series.

1 Integrated Ytterbium fiber laser 20 or 30 W

2 Motor-driven operation door

3 Motor-driven scan head adjustable in height, with a pilot laser to preview the marking

4 Focus finder to set up the marking lane

5 LED lit work area

6 Rotary axis with a 3-jaw chuck to mark cylindrical objects

7 Digital I/O enables control and monitoring, providing 8 freely programmable inputs and outputs

8 Plug to connect the rotary axisOperation panel with function keys, status displays

9 Operation panel with function keys, status displays

10 Groove plate to clamp the workpiece carriers

11 Z-axis, slideable along the groove plate

12 Suction hose

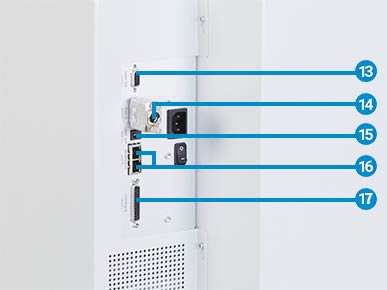

Interfaces

13 External start signal

14 E-stop to integrate into external safety circuits

15 External 24 V for additional operations

16 2 x Ethernet 10/100 Mbit/s

As delivered, the device is configured with an IP address or in DHCP mode.

17 Port to connect the extraction and filter device

| 7.1 | 7.2 | 7.3 | 7.4 | |

| Laser marking system | XENO 1 | |||

|---|---|---|---|---|

| Laser source | Ytterbium fiber laser, pulsed | |||

| cw output power max. W | 20 | 30 | ||

| Puls energy mJ | 1 | |||

| Wave length nm | 1,064 | |||

| Beam quality M2 | <1.8 | |||

| Pulse width ns | <120 | |||

| Pulse frequency kHz | 20 - 60 | 30 - 60 | ||

| Pilot laser / focus finder | ||||

| Wave length nm | 650 | |||

| cw output power mW | <0.4 | |||

| Plano-spherical lenses | 160.2 | 254.2 | 160.2 | 254.2 |

| Working distance mm | 210 ± 8 | 310 ± 8 | 210 ± 8 | 310 ± 8 |

| Marking field mm | 112 x 112 | 180 x 180 | 112 x 112 | 180 x 180 |

| Work area Height mm | 200 | 100 | 200 | 100 |

| Groove plate W x H x D x pitch mm | 500 x 20 x 375 x 25 | |||

| Z axis stroke motor-driven mm | 210 | |||

| Position accuracy mm | ±0.1 | |||

| Repetitive accuracy mm | ±0.1 | |||

| Traversing speed mm/s | 20 | |||

| Interior lighting | LED | |||

| Operating door | motor-driven opening / closeing | |||

| Workpiece weight max. kg | 30 | |||

| Dimemsions and weight | ||||

| Device W x H x D mm | 580 x 660 x 700 | |||

| Device Weight approx. kg | 65 | |||

| Laser protection window W x H mm | 100 x 200 | |||

| Extraction | ||||

| Nozzle flexible hose NW mm | 38 | |||

| Connector extraction NW mm | 50 | |||

| Operating data | ||||

| Power supply | 100-240 VAC, 50/60 Hz | |||

| Power consumption | Standby <35 W / typical 150 W / max. 200 W | |||

| Approvals | CE, FCC class A | |||

| Laser safety class EN60825-1 | Class 1 | |||

| Operation panel | ||||

| LED indicators | Power, Ready, Emission, Error, Marking | |||

| Buttons illuminated | Control ON/OFF Focus finder ON/OFF Extraction ON/OFF LED ON/OFF Start Z axis UP/DOWN Rotary axis LEFT/RIGHT Operation door OPEN/CLOSE |

|||

| Switch | E-stop | |||

| Key switch | automatic / manual | |||

| Monitoring | ||||

| Safety circuits | closed | |||

| Collective error | Marking laser Extraction device |

|||

| Interfaces | ||||

| Work area | Rotary axis Digital I/O |

|||

| Back of device | 2 x Ethernet TCP/IP 24 V for digital I/O Extraction and filter device AF5 External start, external e-stop |

|||

Video: XENO 1 compact all-in-one laser marking system

Never has laser marking been so easy! Sales director Mario Hiss highlights the benefits of XENO 1.

Documentation

-

Catalogs

-

Title Format Version Last change Language Laser marking systems

PDF - 3.48 MB 02/2023 11/04/2023 English

-

-

Case study

-

Title Format Version Last change Language HTI, specialist in lab and manufacture automation: Opening, filling and labeling micro-screw tubes

PDF - 650 KB 11/2022 16/11/2022 English

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Software & Drivers

-

Software

-

Title Format Version Last change Language cabLaseEditor (TCP/IP)

ZIP - 159.79 MB 5.3.2.9 i01 01/02/2022 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader