Label marker

LM+

Mark and cut labels in different sizes out of continuous material

The laser label marker allows precise marking of labels of different sizes straight from the roll and cut them out without the need of additional tools.

The laser label marker allows precise marking of labels of different sizes straight from the roll and cut them out without the need of additional tools.

After the marking, labels made of laser markable foil can be separated by a cutter or externally rewound.

vergrößern

vergrößern

Cutter

Accessories

- 4.3 PC in a 4 height units 19’’ rack

- 4.4 Monitor 23.8’’

- 4.5 Standard keyboard, optical mouse

- 4.6 Keyboard with trackball

- 5.3 External rewinder

- 5.4 Hose set

- 5.5 Mobile cart

- 5.6 Console

- 5.7 Monitor column

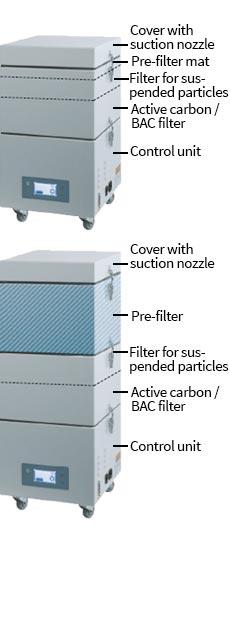

- 6.1 Extraction and filter system AF5

Laser label marker LM+

with a mobile cart, an external rewinder on the console, a column with a monitor attached and an extraction and filter device AF5

Video: LM+ Laser Label Marker

The laser label marker allows to precisely mark and cut labels in different sizes out of continuous material without the need of additional tools.

More videos on LM+: Robot application, pick-up table, peel-off function

XENO 1 is a compact desktop system, offering little footprint and a large work area.

| 4.1 | 4.2 | |

| Laser label marker | LM+160.1 | LM+254.1 |

|---|---|---|

| Work area W x H x D mm | 160 x 5 x 190 | |

| Positioning accuracy mm | 0.2 | |

| Transport speed mm/s | 200 | |

| Interior light | LED | |

| Material | Label or continuous material | |

| Material thickness mm | 0.055-0.3 | |

| Material weight up to g/m2 | 500 | |

| Material width mm | 25-120 | |

| Label height max. mm | 180 | |

| Roll outer diameter max. mm | 300 | |

| Roll core diameter mm | 76 | |

| Roll winding | outside / (inside on request) | |

| Lens Type | 160.2 | 254.2 |

| Marking field mm | 112 x 112 | 120 x 170 |

| Working distance mm | 210 ± 8 | 310 ± 8 |

| Dimensions and weight | ||

| W x H x D mm | 440 x 520 x 802 | |

| Laser protection window WxH mm | 100 x 50 | |

| Machine stands Ø mm | 50 | |

| Suction nozzle Ø mm | 50 | |

| Weight kg | 22 | |

| Operating data | ||

| Operating voltage/frequency | 100-240 VAC ~ 50/60 Hz | |

| Power | ON/OFF | |

| Laser safety class EN60825-1 | Class 1 | |

| Approval | CE | |

| Operation panel | ||

| LED indicators | Continuous material Labels |

|

| Push buttons | Material feed forwards Material feed backwards Cut |

|

| Switches | Automatic / manual E-Stop |

|

| Monitoring | ||

| Safety circuits | closed | |

| Wipe-down roller | locked | |

| Material | In marking position / no material | |

| Interfaces | ||

| Interlock/E-Stop FL+ | ||

| Serial RS232C FL+ Con5 | ||

| External E-Stop | ||

| Cutter | ||

Video: Label marker LM+P with peel-off function

Video: LM+ Laser Label Marker

Powered by YouTube. See all cab videos: cab Channel auf YouTube.

Other formats:

- LM+ Laser Label Marker (MPEG-4, 93 MB)

Video: cab laser label verifier system

Powered by YouTube. See all cab videos: cab Channel auf YouTube.

Other formats:

- cab Laser Label Verifier System (WMV, 20,5 MB)

- cab Laser Label Verifier System (MPEG-4, 5,4 MB)

Download players:

- For WMV: Windows Media Player

- For MPEG-4: VLC Player

Documentation

-

Catalogs

-

Title Format Version Last change Language Laser marking systems

PDF - 2.97 MB 10/2024 23/10/2024 English Overview Product Marking

PDF - 6.61 MB 05/2025 15/05/2025 English

-

-

Case study

-

Title Format Version Last change Language Leica Geosystems: Individual typeplates are marked by laser

PDF - 517 KB 01/2025 08/01/2025 English

-

-

Data sheets

-

Title Format Version Last change Language Consumables approved for LM+ laser marking systems

PDF - 675 KB 02/2023 09/02/2023 English/Deutsch

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Software & Drivers

-

Software

-

Title Format Version Last change Language cabLaseEditor (TCP/IP)

ZIP - 153.58 MB 5.3.4.6 i01 18/09/2024 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader