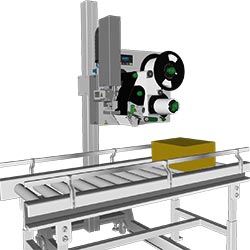

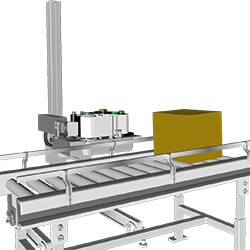

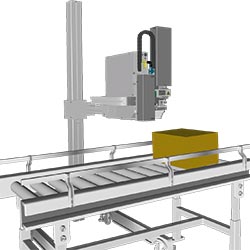

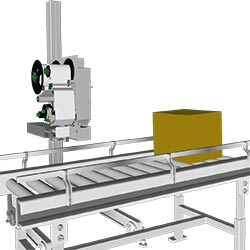

Print and apply systems

HERMES Q

Printing labels and applying them automatically in production lines

The slim one

to print small labels

| 1.1 Label printer | HERMES Q2 | |

|---|---|---|

| Printable resolution dpi | 300 | 600 |

| Print speed up to mm/s | 300 | 150 |

| Print width up to mm | 56.9 | 54.1 |

| Label roll outside diameter mm | 205 / 305 | |

| Label width up to mm | 58 | |

The universal one

An industrial bestseller, providing a wide range of accessories

| 1.2 Label printer | HERMES Q4.3 | HERMES Q4 | ||

|---|---|---|---|---|

| Printable resolution dpi | 200 | 300 | 300 | 600 |

| Print speed up to mm/s | 300 | 300 | 300 | 150 |

| Print width up to mm | 104 | 108.4 | 105.7 | 105.7 |

| Label roll outside diameter mm | 205 / 305 | |||

| Label width up to mm | 114 | |||

The wide one

to print Odette, UCC and GS1 labels in logistics applications

| 1.3 Label printer | HERMES Q6.3 | |

|---|---|---|

| Printable resolution dpi | 200 | 300 |

| Print speed up to mm/s | 250 | 250 |

| Print width up to mm | 168 | 162.6 |

| Label roll outside diameter mm | 205 / 305 | |

| Label width up to mm | 174 | |

Sample applications

Label rolls

All units can provide an unwinder for picking up rolls with maximum diameters either 205 mm or 305 mm.

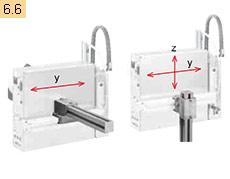

Directions to which dispense labels

All units can be designed for providing labels either to the left or to the right.

left

right

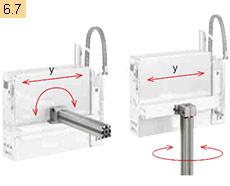

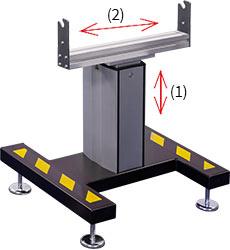

Orientations of assembly

All the units can be rotated vertically by at most 360° or assembled in horizontal orientation.

0º

90º

180º

270º

horizontal

horizontal

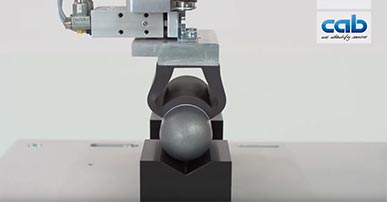

Video: Hermes Q with applicator 4114 and form pad

Labels are applied precisely to cylindric objects, oblique or curved surfaces.

SOTI Connect software enables label printers be configured and managed centrally.

The control panel of our printers can be operated in over 30 languages

HERMES Q in detail

1 Operation panel

1 Operation panel

Self-explanatory symbols are on display. The device can thus be operated intuitively and settings be configured easily.

2 Ribbon holder

On the basis of three-part tightening axles, ribbons can be replaced easily and quickly.

3 Rugged metal chassis

It is made of cast aluminum. All the parts are assembled to it.

4 Applicator

It is assembled to hinge pins. It can be pivoted in case of maintenance or if materials have to be replaced.

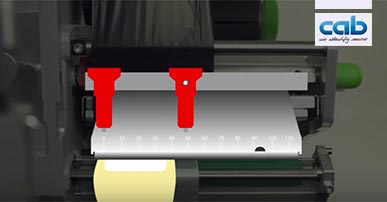

5 Pressing plungers

One is fixed near the chassis wall. The second one is pushed to the label margin, as far as necessary to evoke a good print image.

6 Print head

Units of the same width are interchangeable. Replacement requires only few steps.

7 Print roller

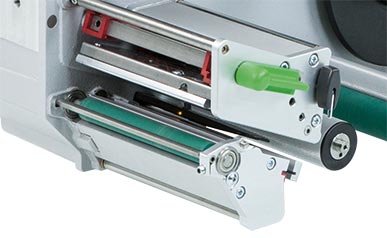

It can be removed/inserted quickly in cases of cleaning or wear.

8 Peel-off plate

Pivoting improves labels be applied to packages.

9 Label unwinder

A swing arm and an integral brake enable labels be unwound at constant force.

10 Liner rewinder

Subsequent to all the labels been dispensed, the entire liner tape is rewound. On the basis of a three-part tightening axle, liner tapes can be inserted and removed easily.

11 Pulling system

A liner tape is clamped between a draw roller and a pinch roller. Labels are dispensed using feed synchronous to the print roller.

12 Label sensor

Imprint is precisely set on spot on a label and materials ending detected by a transmissive or a reflective sensor.

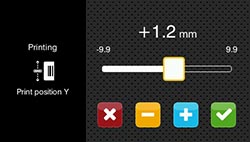

Accurate imprint

The smaller a label, the higher are the demands regarding the accuracy of an imprint. Print offset can be reduced by ±0,2 mm using adjustable slip correction.

Print heads

Units of the same width are interchangeable. They are detected by the CPU automatically and calibrated. The print distance to the locating edge can be adjusted.

Major data such as the operational performance, maximum operating temperature and heat energy are recorded on the print head. Data can be read at the factory.

Print heads provided for HERMES Q2, HERMES Q4 - 300, 600 dpi

- sharp-edge print images

- e.g. when printing small fonts and graphics on typeplates

- e.g. when printing on materials requires high energy needs

Print heads provided for HERMES Q4.3, HERMES Q6.3 - 200, 300 dpi

persistent; when labeling in rough settings and thermal direct method

Print rollers

Two types of materials:

Print rollers DR

providing a synthetic rubber coating

They enable highly accurate imprint and are provided by default.

Print rollers DRS

providing a silicone coating

Product life is extra long, taken a higher print offset into account.

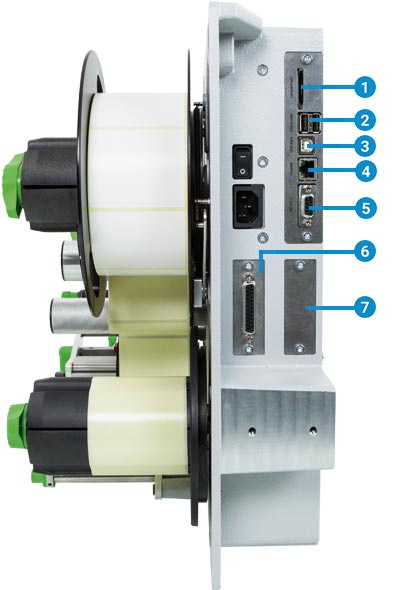

Interfaces

1 to insert a SD memory card

2 2 USB hosts to connect a service key, USB memory stick, keyboard, barcode scanner, USB WLAN stick, warning light, an external operation panel

3 USB 2.0 Hi-Speed to connect a PC

4 Ethernet 10/100 Mbit/s

5 RS232C 1,200 to 230,400 baud / 8 bits

6 Digital I/O interface; socket connector SUB-D, 25 pins compliant with IEC/EN 61131-2, types 1+3

All the inputs and outputs are isolated galvanically and protect from reverse polarity. In addition, outputs are short-circuit proof.

PNP inputs

Start printing or labeling

Print first label

Reprint

Delete print job

Label removed

Stop printing or labeling

Label feed

Label rotated by 90° (to be applied by appl. 4214)

Pause

Reset

PNP, NPN outputs

Device ready

Print data available

Initial / upper end position

Paper feed ON

Label in transfer position

Label application / lower end position

Pre-warning to a ribbon ending

Pre-warning to a label web ending

End of a ribbon and/or a label web

Collective error

Option:

7 2 port Ethernet switch 10/100 Mbit/s

Operation panel

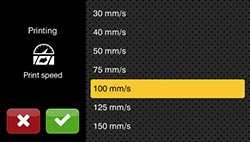

Self-explanatory symbols are on display. The device can thus be operated intuitively and settings be configured easily.

1 LED: Power ON

2 Status bar: data reception, record data stream, pre-warning to a ribbon ending, SD memory card / USB memory stick plugged in, WLAN, Ethernet, USB slave, time

3 Printer status: ready, pause, number of labels printed in a print job, label in transfer position, awaiting external start signal

4 USB slot to connect a service key or a memory stick, to transfer data to the IFFS memory

5 Operation

Printing and applying labels in individual steps

Printing and applying labels in individual steps

Jump to menu

Jump to menu

Reprint the latest label

Reprint the latest label

Interrupt and continue a print job

Interrupt and continue a print job

Stop and delete all print jobs

Stop and delete all print jobs

Label feed

Label feed

Setup options

Print offset Y

Print parameters

Print speeds

Landscape or portrait display, depending from the orientation of assembly

Printer rotated by 90°

Video tutorials

External operation panel

If the operation panel of a printer cannot be accessed, an additional external one can be plugged.

Same functionality as on the printer

Landscape or portrait mode

Operability as desired on the external operation panel or on the printer

Printer connectivity: USB 2.0 Hi-Speed device

1 LED: Power ON

2 USB slot to plug a service key or a memory stick, to transfer data to the IFFS memory

3 Connecting USB cable for power supply cab provides specified cables. Lengths are 1.8 m to 16 m.

SOTI Connect software enables label printers be configured and managed centrally.

The control panel of our printers can be operated in over 30 languages

Technical data

typical

typical  standard

standard  option

option

| Label printer type | HERMES Q2 | HERMES Q4.3 | HERMES Q4 | HERMES Q6.3 | ||||

|---|---|---|---|---|---|---|---|---|

| Printing method Thermal transfer |  |

|

|

|

|

|

|

|

| Printing method Thermal direct | - | - |  |

|

- | - |  |

|

| Printable resolution dpi | 300 | 600 | 200 | 300 | 300 | 600 | 200 | 300 |

| Print speed up to mm/s | 300 | 150 | 300 | 300 | 300 | 150 | 250 | 250 |

| Print width up to mm | 56.9 | 54.1 | 104 | 108.4 | 105.7 | 105.7 | 168 | 162.6 |

| Print length up to mm | 12,000 | 3,000 | 13,500 | 6,000 | 6,000 | 1,500 | 9,000 | 4,000 |

| Direction to which dispense labels | L = to the left / R = to the right | |||||||

| Print distance to locating edge mm | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Print distance to locating edge with automatic saving L/R mm | - | - | 2.2/1.6 | 0/-0.7 | 1/1 | 1/1 | 0.2/0.2 | 2.9/2.9 |

| UHF RFID | ||||||||

| UHF RFID module | - | - |  |

|

|

|

|

|

| Materials | ||||||||

| Labels | Paper, PET, PE, PP, PI, PVC, PU, acrylate, Tyvec | |||||||

| Labels on a roll |  |

|

|

|

||||

| Labels on a reel |  |

- | - | - | ||||

| Labels1) Width mm | 4 - 58 | 10 - 114 | 10 - 114 | 46 - 174 | ||||

| Labels Height from mm | 3 | 4 | 4 | 6 | ||||

| Labels Thickness up to mm | 0.60 | 0.60 | 0.60 | 0.60 | ||||

| Liner tape Width if operating a roll mm | 24 - 62 | 24 - 118 | 24 - 118 | 50 - 178 | ||||

| Liner tape Width if operating a reel or a roll2) mm | 10 - 24 | - | 10 - 24 | - | ||||

| Liner tape Thickness mm | 0.03 - 0.08 | 0.03 - 0.08 | 0.03 - 0.08 | 0.03 - 0.08 | ||||

| Roll unwinder Outside roll diameter up to mm | 205 / 305 | 205 / 305 | 205 / 305 | 205 / 305 | ||||

| Roll unwinder Outside reel diameter up to mm | 205 | - | - | - | ||||

| Roll unwinder Core diameter mm | 76 | |||||||

| Roll unwinder Winding | outside or inside | |||||||

| Roll rewinder Outside diameter up to mm | 155 / 205 | |||||||

| Roll rewinder Core diameter mm | 76 | |||||||

| Ribbon3) Ink side | outside or inside | |||||||

| Ribbon Roll diameter up to mm | 90 | |||||||

| Ribbon Core diameter mm | 25.4 | |||||||

| Ribbon Length up to m | 600 | |||||||

| Ribbon Width mm | 25 - 67 | 25 - 114 | 25 - 114 | 50 - 170 | ||||

| Ribbon Automatic ribbon saving | - |  |

|

|

||||

| Printer dimensions and weights | ||||||||

| Width mm | 207 | 260 | 260 | 320 | ||||

| Height roll diameter 205 / 305 mm | 400 / 430 | |||||||

| Depth roll diameter 205 / 305 mm | 400 / 500 | |||||||

| Weight roll diameter 205 / 305 approx. kg | 15 / 16 | 16 / 17 | 16 / 17 | 20 | ||||

| Label sensor indicating positions | ||||||||

| Transmissive sensor detecting | labels, punch marks or print marks, as well as materials ending | |||||||

| Reflective sensor bottom reflex detecting | print marks on non-transparent liners, as well as materials ending | |||||||

| Sensor distance to the locating edge standard mm | 2 - 12 | 2 - 60 | 2 - 60 | 2 - 60 | ||||

| Sensor distance to the locating edge modified mm | 2 - 26 | |||||||

| Material passage mm | 2 | |||||||

| Electronics | ||||||||

| 32-bit processor MHz | 800 | |||||||

| RAM MB | 256 | |||||||

| IFFS memory MB | 50 | |||||||

| Slot to insert a memory card (SDHC, SDXC) |  |

|||||||

| Battery to display date and real time |  |

|||||||

| Data (e.g. serial numbering) preserved if power turns off |  |

|||||||

| Interfaces | ||||||||

| RS232C 1,200 to 230,400 baud / 8 bit |  |

|||||||

| USB 2.0 Hi-Speed to connect a PC |  |

|||||||

| Ethernet 10/100 Mbit/s | LPD, RawIP-Printing, SOAP-Webservice, OPC UA, WebDAV, DHCP, HTTP/HTTPS, FTP/FTPS, TIME, NTP, Zeroconf, SNMP, SMTP, VNC | |||||||

| 2 USB hosts on the control panel, 2 USB hosts on the back of a unit |

Service key, USB stick, USB WLAN stick, USB WLAN stick including a rod antenna, keyboard, barcode scanner, warning light, external control panel | |||||||

| USB host 24 VDC, to connect a peripheral device |  |

|||||||

| Digital I/O interface, 10 inputs / 11 outputs |  |

|||||||

| Interface for plugging an external label sensor |  |

|||||||

| 2 port Ethernet switch 10/100 Mbit/s |  |

|||||||

| Operating data | ||||||||

| Voltage | 100-240 VAC, 50/60 Hz, PFC | |||||||

| Power consumption | standby < 10 W / typical 100 W / max. 200 W | |||||||

| Temperature / humidity: Operation | + 5 - 40°C / 10 - 85% not condensing | |||||||

| Temperature / humidity: Stock | 0 - 60°C / 20 - 85% not condensing | |||||||

| Temperature / humidity: Transport | – 25 - 60°C / 20 - 85% not condensing | |||||||

| Approvals | CE, UKCA, FCC Class A, ICES-3, cULus, CB, CCC, BSMI, KC-Mark, Mexico Reg., RCM | |||||||

For more technical data please read the product brochure (PDF)

- Limitations can occur when processing small labels, thin materials or materials using a strong adhesive. Critical applications need testing.

- Spacers attached to the label unwinder and the unit rewinding the liner tape help feeding the ribbon centered above the labels.

- The ribbon must correspond at least to the width of the liner tape.

SOTI Connect software enables label printers be configured and managed centrally.

The control panel of our printers can be operated in over 30 languages

| 1.1 | 1.2 | 1.3 | |||||

| Pos | Designation | roll Ø 205 | roll Ø 305 | HERMES Q2 | HERMES Q4.3 | HERMES Q4 | HERMES Q6.3 |

|---|---|---|---|---|---|---|---|

| 2.1 | SD memory card 8 GB |  |

|

|

|

|

|

| 2.2 | USB memory stick 8 GB |  |

|

|

|

|

|

| 2.3 | USB WLAN stick |  |

|

|

|

|

|

| 2.4 | USB WLAN stick including a rod antenna |  |

|

|

|

|

|

| 2.5 | USB Bluetooth adapter |  |

|

|

|

|

|

| 2.6 | Product sensor, 3 pin |  |

|

- |  |

|

|

| 2.7 | Product sensor, 25 pin |  |

|

|

|

|

|

| 2.8 | I/O interface connector SUB-D, 25 pin |  |

|

|

|

|

|

| 2.9 | Warning light |  |

|

|

|

|

|

| 2.10 | External operation panel |  |

|

|

|

|

|

| Connection cable USB |  |

|

|

|

|

|

|

| 2.11 | Label selection - I/O box |  |

|

|

|

|

|

| 2.12 | Hand switch TR2 |  |

|

|

|

|

|

| 2.13 | Foot switch |  |

|

|

|

|

|

| 2.14 | Connecting RS232 C cable |  |

|

|

|

|

|

| 2.15 | Scanner CC200 |  |

|

|

|

|

|

Suitable applicators you will find: HERMES Q applicators

Accessories are plugged or screwed to a printer by the customer.

Options

are parts or units to perform special functions. They are assembled to a printer in addition to or instead of standards. If order implies options be assembled ex factory, the part numbers of such printers and options are added by .250. Options delivered separately are added by .001.

| Pos | Designation | roll Ø 205 | roll Ø 305 | HERMES Q2 | HERMES Q4.3 | HERMES Q4 | HERMES Q6.3 | .250 | .001 | .486 | .488 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 3.1 | Automatic ribbon saving |  |

|

- |  |

|

|

|

- | - | - |

| 3.2 | UHF RFID module RS |  |

|

- |  |

|

|

|

- |  |

- |

| UHF RFID module HS |  |

|

- |  |

|

|

|

- | - |  |

|

| 3.3 | Label unwinder K40 |  |

|

|

|

|

|

|

|

- | - |

| 3.4/3.5 | Adapter 40/50 and 76/100 |  |

|

|

|

|

|

|

|

- | - |

| 3.6 | Spacers |  |

- |  |

|

|

- |  |

|

- | - |

| 3.7 | Margin stop 10 |  |

- |  |

|

|

|

|

|

- | - |

| 3.8 | Cover |  |

- |  |

|

|

|

|

|

- | - |

| 3.9 | Print head pressure system, reduced force |  |

|

|

|

|

|

|

|

- | - |

| 3.10 | Extended peel-off plate (+10 mm) |  |

|

|

|

|

|

|

|

- | - |

| 3.11 | Print roller DRS |  |

|

|

|

|

|

|

|

- | - |

| 3.12 | Antistatic brush |  |

|

|

|

|

- |  |

|

- | - |

| 3.13 | Draw roller ZS |  |

|

|

|

|

|

|

|

- | - |

| 3.14 | Interface for plugging an external label sensor |  |

|

|

|

|

|

|

|

- | - |

| 3.15 | 2 port Ethernet switch 10/100 Mbit/s |  |

|

|

|

|

|

|

|

- | - |

| 3.16 | Label sensor, modified |  |

|

|

- | - | - |  |

|

- | - |

Automatic ribbon saving

assembly ex factory only

Use is recommended in cases of at least 60 mm unprinted area on a label. While labels are fed, the print head is lifted and the ribbon stopped, resulting in less material consumption.

UHF RFID module

assembly to a printer ex factory excludes automatic ribbon saving

Read/write antennas are assembled directly to a print head or a feeding unit. Using a 4214 applicator enables defective labels be ejected.

More information on cab UHF RFID label printers

Label unwinder K40

to process label rolls having a core diameter of 40 mm

Adapter 40/50

to pick up label rolls having a core diameter of 50 mm and minimum widths of 20 mm. One adapter is sufficient if material width does not exceed 50 mm.

Adapter 76/100

to pick up label rolls having a core diameter of 100 mm and minimum widths of 20 mm. One adapter is sufficient if material width does not exceed 50 mm.

Spacers

to process narrow labels provided on liners ≤ 20 mm wide, wound on a roll or a reel.

Ribbon protruding on both sides prevents from wrinkling. The label guidance is therefore offset by 7 mm from the middle wall with spacers. A modified label sensor is included on delivery.

Reel plate wall thickness 1 - 2 mm

Label sensor, modified

Provided for labels requiring a sensor distant up to 26 mm to the locating edge. This sensor cannot be fixed with a screw.

Margin stop 10

to guide narrow labels provided on a liner 10 - 24 mm wide, wound on a roll (no reels) having a core diameter of 76 mm.

Operate only with a spacer

Cover

to prevent from contamination and contact

to prevent from contamination and contact

Maximum outside diameter for label rolls is 205 mm

Assembly in vertical orientation, rotated by ± 90° or horizontally

Depth of a pad immersing Dim. F

| Dimension F mm | |||

|---|---|---|---|

| Standard | Optional | on request | |

| HERMES Q2 | 60 | 100 | up to 120 |

| HERMES Q4/Q4.3 | 60 | 100 | up to 120 |

| HERMES Q6 | 25 | - | up to 120 |

Print head pressure system, reduced force

Thermal direct printing requires less pressure on a print head. Reduced force results in a decrease of wear. Product life extends.

Thermal direct printing requires less pressure on a print head. Reduced force results in a decrease of wear. Product life extends.

Thermal direct printing only

Extended peel-off plate (+10 mm)

Recommended

Recommended

- if labels are picked up by a robotic arm,

- if readable area is required for scanning,

- when installing an antistatic brush

Print roller DRS

Silicone coating enables an extra long product life, taken a higher print offset into account.

Silicone coating enables an extra long product life, taken a higher print offset into account.

Antistatic brush

Electrostatic charge is reduced when plastic labels are printed and peeled off.

Electrostatic charge is reduced when plastic labels are printed and peeled off.

Operate only with an extended peel-off plate.

Draw roller ZS

Made of steel, to avoid tension on a liner tape:

Made of steel, to avoid tension on a liner tape:

- if label height exceeds 150 mm

- when peeling off without backfeed

- if thick liner materials are processed

- when applying labels using a demand module 5114/16

Interface for plugging an external label sensor

M12 plug, 5 pins, a-coded

M12 plug, 5 pins, a-coded

Plug-compatible with CEON and other sensors based on PNP and 24 V

2-Port Ethernet Switch 10/100 Mbit/s

to connect another terminal device in a joint network. Signals are looped through.

to connect another terminal device in a joint network. Signals are looped through.

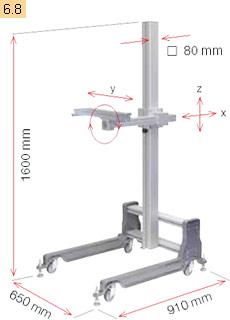

Video: Labeling moving objects with the help of a robot

Powered by YouTube. See all cab videos: cab channel on YouTube.

Using an external robot, we have tested different label formats be applied flexibly to moving objects. The two HERMES Q label printers can also be equipped with a uniform label format, resulting in "zero downtime".

Other format:

- Labeling moving objects with the help of a robot (MPEG-4; 156 MB)

Video: Labeling non-moving objects with the help of a robot

Powered by YouTube. See all cab videos: cab channel on YouTube.

cab shows in this study the universal labeling of different label formats and flexible labeling positions with a robot. Alternatively, the label printers are equipped with both the same label format and ensure continuous operation at media end.

Other format:

- Labeling non-moving objects with the help of a robot (MPEG-4; 162.2 MB)

Video: Hermes Q with applicator 4114 and silicone form pad

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- Hermes Q with applicator 4114 and silicone form pad (MPEG-4, 52,9 MB)

cab Video Tutorials

Download players:

- For WMV: Windows Media Player

- For MPEG-4: VLC Player

Documentation

-

Catalogs

-

Title Format Version Last change Language HERMES Q with HQ applicators

PDF - 6.39 MB 04/2025 17/04/2025 English Labeling cables

PDF - 1.38 MB 06/2024 12/12/2024 English UHF RFID label printers

PX Q | HERMES Q | XD Q | SQUIXPDF - 860 KB 03/2025 18/03/2025 English Overview Product Marking

PDF - 6.61 MB 05/2025 15/05/2025 English

-

-

Assembly Instructions

-

Title Format Version Last change Language Assembly Instructions HERMES Q

PDF - 2.93 MB 07/2024 12/07/2024 English -

Other languages

-

Title Format Version Last change Language HERMES Q 标签打印机安装说明书

PDF - 3.71 MB 07/2024 12/07/2024 简体字 HERMES Q 標簽打印機安裝說明書

PDF - 3.76 MB 07/2024 12/07/2024 繁體字 Návod k montáži HERMES Q

PDF - 2.97 MB 07/2024 12/07/2024 Čeština Monteringsvejledning HERMES Q

PDF - 2.92 MB 07/2024 12/07/2024 Dansk Montagehandleiding HERMES Q

PDF - 2.92 MB 07/2024 12/07/2024 Nederlands Asennusohje HERMES Q

PDF - 2.88 MB 07/2024 12/07/2024 Suomi Szerelési útmutató HERMES Q

PDF - 2.96 MB 07/2024 12/07/2024 Magyar Instrukcja montażu HERMES Q

PDF - 2.97 MB 07/2024 12/07/2024 Polski Instruções de montagem HERMES Q

PDF - 2.95 MB 07/2024 12/07/2024 Português Instrucțiuni de montaj HERMES Q

PDF - 2.96 MB 07/2024 12/07/2024 Română Руководство по монтажу HERMES Q

PDF - 2.99 MB 07/2024 12/07/2024 Pусский Navodila za montažo HERMES Q

PDF - 2.95 MB 07/2024 12/07/2024 Slovenščina Instrucciones de montaje de la impresora de etiquetas HERMES Q

PDF - 2.90 MB 10/2019 30/11/2020 Español Monteringsanvisning HERMES Q

PDF - 2.92 MB 07/2024 12/07/2024 Svensk HERMES Q - 조립 설명서

PDF - 3.21 MB 07/2024 12/07/2024 한국어 Instrucciones de montaje HERMES Q

PDF - 2.94 MB 07/2024 12/07/2024 Español Istruzioni di montaggio HERMES Q

PDF - 2.94 MB 07/2024 12/07/2024 Italiano Montageanleitung HERMES Q

PDF - 2.93 MB 07/2024 12/07/2024 Deutsch Notice d'assemblage HERMES Q

PDF - 2.94 MB 07/2024 12/07/2024 Français

-

-

-

Interface Descriptions

-

Information on the interface type can be found on the original cab packaging, in the printer status report after installation or as a label next to the SUB-D connection.

Title Format Version Last change Language Interface Description I/O 24V25-2 and I/O 24V25-3

PDF - 278 KB 05/2025 16/05/2025 English Interface Description I/O 24V25-4

PDF - 278 KB 05/2025 16/05/2025 English -

Other languages

-

Title Format Version Last change Language Description de l'interface I/O 24V25-4

PDF - 301 KB 05/2025 16/05/2025 Français Description des interfaces I/O 24V25-2 et I/O 24V25-3

PDF - 302 KB 05/2025 16/05/2025 Français Schnittstellenbeschreibung I/O 24V25-2 und I/O 24V25-3

PDF - 265 KB 05/2025 16/05/2025 Deutsch Schnittstellenbeschreibung I/O 24V25-4

PDF - 268 KB 05/2025 16/05/2025 Deutsch

-

-

-

Configuration Manuals

-

Title Format Version Last change Language Configuration manual cab Label Printers

from SN 14089PDF - 2.57 MB 08/2024 19/08/2024 English -

Other languages

-

Title Format Version Last change Language Konfigurationsanleitung cab-Etikettendrucker

ab SN 14089PDF - 2.60 MB 08/2024 19/08/2024 Deutsch Manuel de configuration imprimantes d'étiquettes cab

à partir du numéro de série 0014089PDF - 2.66 MB 08/2024 19/08/2024 Français

-

-

-

Programming

-

Title Format Version Last change Language cab Remote Control

Remote control of cab systems for label printing / Fernsteuerung von cab Drucksystemen - HERMES Q, SQUIX, PX QZIP - 3.50 MB 2021/07 15/01/2025 English/Deutsch PLC Programmer's Guide HERMES Q, SQUIX, XD Q, PX Q

with label layouts and programming examplesZIP - 16.17 MB 06/2020 15/01/2025 English Brief introduction to cab printer programming

PDF - 7.47 MB 04/2022 15/01/2025 English cab Download Converter (download.exe)

Converts image, font and database files into the JScript download data format.

Install MS Visual C++ 2010 Redistributable if not available on your system.ZIP - 9 KB 2.3 25/10/2024 – cabPROTECT - Data security in label printing

PDF - 472 KB 06/2024 20/06/2024 English Connecting cab printing systems to SAP®

CompendiumPDF - 4.45 MB 01/2025 11/02/2025 English Networked labeling with OPC UA

cab and the Smart FactoryPDF - 1.12 MB 03/2019 15/01/2025 English Programming Manual abc Basic Compiler

for cab printersPDF - 755 KB 11/2024 29/11/2024 English Programming Manual JScript

for SQUIX, MACH 4S, EOS2, EOS5, XC Q, XD Q, HERMES Q, PX Q, AXON1, AXON 2, A+, HERMES+, A-Series, EOS1/4, MACH4, XD, XCPDF - 4.30 MB 05/2025 23/05/2025 English ZPL Emulation with cab printers

PDF - 2.28 MB 05/2025 23/05/2025 English -

Other languages

-

Title Format Version Last change Language Anbindung von cab Drucksystemen an SAP®

KompendiumPDF - 4.55 MB 01/2025 11/02/2025 Deutsch cabPROTECT - Datensicherheit beim Etikettendruck

PDF - 475 KB 06/2024 20/06/2024 Deutsch Kurze Einführung in die cab Druckerprogrammierung

PDF - 7.50 MB 04/2022 12/04/2022 Deutsch Marquage en réseau avec OPC UA

cab et l'usine intelligentePDF - 745 KB 01/2022 23/10/2024 Français SPS Programmieranleitung HERMES Q, SQUIX, XD Q, PX Q

mit Etikettenlayouts und BeispielprogrammenZIP - 16.22 MB 06/2020 18/04/2024 Deutsch Vernetzt kennzeichnen mit OPC UA

cab und die intelligente FabrikPDF - 1.13 MB 03/2019 28/01/2021 Deutsch

-

-

-

Service Manuals

-

Title Format Version Last change Language Service Manual HERMES Q

PDF - 3.03 MB 05/2025 21/05/2025 English -

Other languages

-

Title Format Version Last change Language Serviceanleitung HERMES Q

PDF - 3.02 MB 05/2025 21/05/2025 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List HERMES Q left

PDF - 2.12 MB 10/2024 05/11/2024 English Spare Parts List HERMES Q right

PDF - 2.15 MB 10/2024 20/01/2025 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste HERMES Q links

PDF - 2.13 MB 10/2024 05/11/2024 Deutsch Ersatzteilliste HERMES Q rechts

PDF - 2.16 MB 10/2024 20/01/2025 Deutsch

-

-

-

Assembly Instructions Spare Parts

-

Title Format Version Last change Language 9004105 | Druckkopfwechsel / Printhead Replacement: SQUIX, HERMES Q, MACH 4S, EOS2, EOS5, PX Q, AXON1, XC Q, XD Q

PDF - 5.70 MB 06/2024 18/06/2024 English/Deutsch

-

-

cab Video Tutorials

-

Title Format Version Last change Language How to adjust the light barrier at HERMES Q?

– 01/2020 08/04/2024 – How to adjust the pressure system of HERMES Q?

– 01/2020 08/04/2024 – How to clean print roller at HERMES Q?

– 01/2020 08/04/2024 – How to clean printhead at HERMES Q?

– 01/2020 08/04/2024 – How to load labels in the HERMES Q?

– 01/2020 08/04/2024 – How to load ribbon in HERMES Q?

– 01/2020 08/04/2024 –

-

-

Feed Path Schemes

-

Title Format Version Last change Language Feed Path Scheme HERMES QL-2

Open the file in Adobe Acrobat Reader to interactively adapt the schemas to the specific application.PDF - 65 KB 07/2019 24/05/2023 English Feed Path Scheme HERMES QL-3

Open the file in Adobe Acrobat Reader to interactively adapt the schemas to the specific application.PDF - 64 KB 07/2019 24/05/2023 English Feed Path Scheme HERMES QR-2

Open the file in Adobe Acrobat Reader to interactively adapt the schemas to the specific application.PDF - 56 KB 07/2019 24/05/2023 English Feed Path Scheme HERMES QR-3

Open the file in Adobe Acrobat Reader to interactively adapt the schemas to the specific application.PDF - 54 KB 07/2019 24/05/2023 English -

Other languages

-

Title Format Version Last change Language Einlegeschema HERMES QL-2

Öffnen Sie die Datei im Adobe Acrobat Reader, um interaktiv die Schemas an die konkrete Anwendung anzupassen.PDF - 47 KB 07/2019 24/05/2023 Deutsch Einlegeschema HERMES QL-3

Öffnen Sie die Datei im Adobe Acrobat Reader, um interaktiv die Schemas an die konkrete Anwendung anzupassen.PDF - 46 KB 07/2019 24/05/2023 Deutsch Einlegeschema HERMES QR-2

Öffnen Sie die Datei im Adobe Acrobat Reader, um interaktiv die Schemas an die konkrete Anwendung anzupassen.PDF - 47 KB 07/2019 24/05/2023 Deutsch Einlegeschema HERMES QR-3

Öffnen Sie die Datei im Adobe Acrobat Reader, um interaktiv die Schemas an die konkrete Anwendung anzupassen.PDF - 45 KB 07/2019 24/05/2023 Deutsch Schémas de mise en place des cons. HERMES QL-2

Ouvrez le fichier avec Adobe Reader afin de sélectionner le type de consommables pour obtenir le schéma de mise en place correspondantPDF - 56 KB 07/2019 24/05/2023 Français Schémas de mise en place des cons. HERMES QL-3

Ouvrez le fichier avec Adobe Reader afin de sélectionner le type de consommables pour obtenir le schéma de mise en place correspondantPDF - 55 KB 07/2019 24/05/2023 Français Schémas de mise en place des cons. HERMES QR-2

Ouvrez le fichier avec Adobe Reader afin de sélectionner le type de consommables pour obtenir le schéma de mise en place correspondantPDF - 56 KB 07/2019 24/05/2023 Français Schémas de mise en place des cons. HERMES QR-3

Ouvrez le fichier avec Adobe Reader afin de sélectionner le type de consommables pour obtenir le schéma de mise en place correspondantPDF - 54 KB 07/2019 24/05/2023 Français

-

-

-

Manuals Accessories

-

Title Format Version Last change Language Bracket - Assembly Instructions

PDF - 105 KB 08/2019 08/12/2020 English PCB External Label Sensor - Assembly Instructions

PDF - 457 KB 02/2023 14/07/2023 English Spacers - Assembly Instructions

PDF - 449 KB 06/2021 08/02/2023 English Compressed Air Regulation Unit - Assembly Instructions

PDF - 230 KB 11/2024 12/11/2024 English Compressed Air Regulation Unit with Shut-off Valve - Assembly Instructions

PDF - 323 KB 08/2019 08/02/2023 English Label File Selection Box - Input Output Box - Instructions

PDF - 329 KB 04/2023 12/04/2023 English External Operation Panel - Instructions

PDF - 274 KB 04/2023 12/04/2023 English Product Sensor I/O - Mounting Instructions

PDF - 120 KB 08/2019 08/12/2020 English 2-Port Ethernet Switch - Assembly Instructions

PDF - 162 KB 09/2019 08/02/2023 English Warning Light - Assembly Instructions

PDF - 303 KB 06/2020 08/02/2023 English Cover - Assembly Instructions

PDF - 166 KB 08/2020 08/02/2023 English -

Other languages

-

-

EU Declarations of Conformity - Accessories

-

Title Format Version Last change Language EU Declaration of Conformity CC200-HQ

PDF - 71 KB 11/2022 17/11/2022 English Label File Selection Box - I/O Box - EU Declaration of Conformity

PDF - 30 KB 07/2019 02/02/2023 English External Operation Panel - EU Declaration of Conformity

PDF - 30 KB 07/2019 02/02/2023 English 2-Port Ethernet Switch - EU Declaration of Conformity

PDF - 30 KB 09/2019 08/12/2020 English Warning Light - EU Declaration of Conformity

PDF - 98 KB 06/2020 08/12/2020 English Present Sensor PS 4/900 HQ 4L EU Declaration of Conformity

PDF - 71 KB 09/2022 30/09/2022 English -

Other languages

-

Title Format Version Last change Language 2-Port Ethernet Switch - Konformitätserklärung

PDF - 30 KB 09/2019 08/12/2020 Deutsch Balise d’alarme lumineuse - Déclaration UE de conformité

PDF - 97 KB 06/2020 08/12/2020 Français Déclaration UE de conformité CC200-HQ

PDF - 71 KB 11/2022 17/11/2022 Français Etikettenauswahlbox - Ein-/Ausgabebox - Konformitätserklärung

PDF - 30 KB 07/2019 02/12/2020 Deutsch EU-Konformitätserklärung CC200-HQ

PDF - 72 KB 11/2022 17/11/2022 Deutsch Externes Bedienfeld - Konformitätserklärung

PDF - 30 KB 07/2019 02/12/2020 Deutsch Labelbox - I/O Box - Déclaration UE de conformité

PDF - 30 KB 07/2019 02/12/2020 Français Meldeleuchte - Konformitätserklärung

PDF - 99 KB 06/2020 08/12/2020 Deutsch Panneau de commande externe - Déclaration UE de conformité

PDF - 30 KB 07/2019 02/12/2020 Français

-

-

-

Case study

-

Title Format Version Last change Language High voltage at Mennekes: Electric vehicle charging cables, explicitly labeled

PDF - 672 KB 07/2023 10/07/2023 English HTI, specialist in lab and manufacture automation: Opening, filling and labeling micro-screw tubes

PDF - 650 KB 11/2022 16/11/2022 English

-

-

Safety data sheets

-

Title Format Version Last change Language Safety Data Sheet Special Cleaner for Glass and Plastic GR1N

PDF - 65 KB 08/2017 23/10/2024 English Safety Data Sheet Special Rubber Cleaner WR1

PDF - 76 KB 12/2017 23/10/2024 English -

Other languages

-

Title Format Version Last change Language Sicherheitsdatenblatt Spezial Glasreiniger und Kunststoffreiniger GR1N

PDF - 156 KB 06/2017 25/08/2022 Deutsch Sicherheitsdatenblatt Spezial-Gummiwalzen-Reiniger WR1

PDF - 173 KB 06/2017 25/08/2022 Deutsch

-

-

3D CAD models

The files are provided in STEP format, which requires CAD software. Follow this link to download a free STP Viewer: VariCAD Viewer (External website).

Select the desired model and click on the link. A short registration follows. cab will handle your personal information as described in our Privacy statement. This information will not be accessible to any third party for marketing purposes. You will receive an email with an activation link and you can download the models.

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Ready to interact with machines and components of different manufacturers in industrial plants.

Interface modeled by cab for robotics operations of tomorrow.

Here you can download firmware, drivers and software. Documentation on label software, printers programming and administration as well as integration of cab printers into SAP systems:

Label software

Software & Drivers

-

Firmware

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Firmware X4

Firmware SQUIX | EOS2 | EOS5 | MACH 4S | XD Q | XC Q | HERMES Q | PX Q | AXONZIP - 53.66 MB 5.46.4 05/06/2025 – Release Notes Firmware X4

TXT - 123 KB

TXT - 123 KB

5.00 - 5.46.4 05/06/2025 –

-

-

Firmware periphery

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Firmware applicators SQ, HQ

ZIP - 49 KB 2.1.0 08/04/2025 – Firmware I/O 24V25-2, I/O 24V25-3, I/O 5V15-2 and I/O 5V15-3

ZIP - 23 KB 3.2.0 08/04/2025 –

-

-

Drivers

-

Title Format Version Last change Language cab Linux Armv7 - 32 Bit Driver

CUPS Linux Armv7 32bit Driver RPi 2/3/4 (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab Linux Armv8(aarch64) - 64 Bit Driver

CUPS Linux Armv8 64 Bit Driver RPi 3/4 (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab Linux x86 - 32 Bit Driver

CUPS Linux Intel 32bit Driver (min. CUPS 1.2)GZ - 2.81 MB 1.46 23/10/2024 – cab Linux x86 - 64 Bit Driver

CUPS Linux Intel/AMD 64bit Driver (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab MAC OS Driver

Apple® Mac OS 10.15 - 15.4ZIP - 2.97 MB 1.46 01/04/2025 – cab MAC OS X Driver

Apple® Mac OS X 10.6 - 10.14ZIP - 5.82 MB 1.46 23/10/2024 – cab Windows Driver ARCHIV

Vista, Windows 7, Windows 8, Windows 8.1, Windows 10, Windows Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019 - 32/64 Bit CERTIFIEDZIP - 9.37 MB 5.3.03 21/02/2024 – cab Windows Driver NEW

Windows 10, Windows 11, Windows Server 2016, Windows Server 2019, Windows Server 2022 - 64Bit, requires Visual C++ 2022ZIP - 24.01 MB 1.4.1.0 24/03/2025 – cab Windows Driver NEW Release Notes

PDF - 120 KB 1.2.1.20 - 1.4.1.0 24/03/2025 –

-

-

Software

-

Title Format Version Last change Language cab Download Converter (download.exe)

Converts image, font and database files into the JScript download data format.

Install MS Visual C++ 2010 Redistributable if not available on your system.ZIP - 9 KB 2.3 25/10/2024 – cablabel S3 Demo (Free)

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 51.42 MB 1.4.0.9 30/06/2025 – cablabel S3 Lite (Free)

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 68.19 MB 1.4.0.9 26/11/2024 – cablabel S3 Print

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 57.82 MB 1.4.0.9 30/06/2025 – cablabel S3 Pro

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 68.64 MB 1.4.0.9 30/06/2025 – Database Connector

Windows 32 & 64 bitZIP - 10.93 MB 4.3.0.1 25/10/2024 – LogService

for Database ConnectorZIP - 4.15 MB 1.7.1.0 25/10/2024 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Ready to interact with machines and components of different manufacturers in industrial plants.

Interface modeled by cab for robotics operations of tomorrow.