Off-cut remover

HEKTOR 2

Separates milled PCBs carefully and quickly

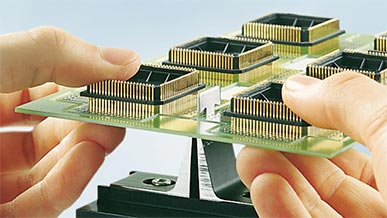

PCBs are separated carefully and quickly, off-cuts are removed precisely and smoothly. A two-part matrix enables the different blades to be assembled resp. exchanged easily.

Off-cuts are punched out with the help of a compressed air cylinder. The operating pressure can be set on the unit.

Safe operation with HEKTOR 2

PCBs are positioned with their milled groove over the blade onto the matrix. The off-cut is fed below the punch blade. A foot switch triggers the punching and the off-cut is collected in the bottom tool.

T blade

T blade

to punch out off-cuts on the right and left margins. Turning the PCB is not necessary

L blade

L blade

used with small distances between the off-cuts

Matrix

included in the scope of delivery

| Technical data | HEKTOR 2 |

|---|---|

| Separation method | Punch blade |

| Operation | manual |

| PCB thickness | up to 2.5 mm |

| Air pressure supply | 1/4" coupling socket |

| Operating pressure, typical | 4 bar |

| Temperature / humidity Operation Temperature / humidity Stock Temperature / humidity Transport |

+ 10 - 35°C / 10 - 85 % not condensing 0 - 60° C / 20 - 80 % not condensing – 25 - 60°C / 20 - 80 % not condensing |

| Width x Height x Depth | 220 x 170 x 255 mm |

| Weight | 2.7 kg |

| Approvals | CE, FCC Class A |

For more technical data please read the product brochure (PDF)

Documentation

-

Catalogs

-

Title Format Version Last change Language Products for the Electronic Industry

PCB Separators and PCB MagazinesPDF - 6.31 MB 10/2022 16/04/2025 English

-

-

Operation Manuals

-

Title Format Version Last change Language Operator's Manual Hektor 2

PDF - 375 KB 05/2019 29/05/2019 English

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List HEKTOR 2

PDF - 215 KB 11/2024 13/01/2025 English

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader