Print module

PX Q

for industrial use

Printing and labeling fully automatically in industrial applications

Printing and labeling fully automatically in industrial applications

Full functionality, high reliability, comfortable operation and low downtime related to maintenance! The PX Q print and peel-off module has been designed specifically for printing and labeling fully automatically in industrial applications. It can be integrated in any orientation of assembly to solve even complex marking tasks.

A torsion-resistant cast aluminum construction is basis to assemble all the components of the print mechanics. Food-safe coating and stainless steel casings add to the perfect shape with special features. Screwing is compatible to the devices of competitors.

The universal one

Industrial device for accurate imprint.

| 1.1 Print module | PX Q4.3 | PX Q4 | ||

|---|---|---|---|---|

| Printable resolution dpi | 203 | 300 | 300 | 600 |

| Print speed up to mm/s | 250 | 250 | 300 | 150 |

| Print width up to mm | 104 | 108.4 | 105.7 | 105.7 |

The wide one

Suitable for Odette and UCC labels

| 1.2 Print module | PX Q6.3 | |

|---|---|---|

| Printable resolution dpi | 203 | 300 |

| Print speed up to mm/s | 250 | 250 |

| Print width up to mm | 168 | 162.6 |

PX Q print module 'L'

to the left

PX Q print module 'R'

to the right

Directions of label transfer

All the print modules are provided as left-hand and right-hand versions. As for printable resolutions, PX Q users can choose from 300 and 600 dpi, the PX Q4.3 and PX Q6.3. offer 203 and 300 dpi.

SOTI Connect software enables label printers be configured and managed centrally.

The control panel of our printers can be operated in over 30 languages

1 Operation panel

1 Operation panel

Operating the device is intuitive and simple with the help of self-explanatory symbols to configure settings

2 Ribbon holder

Three-part tightening axles enable the ribbon to be replaced quickly and easily.

3 Rugged metal chassis

made of cast aluminum; basis to assemble all units

4 Plungers

One plunger is fixed on the inner side. A second one is moved that far to the label margin, until a good print image evokes.

5 Print head

All print heads are freely interchangeable at equal width. Easy replacement

6 Automatic ribbon saving (option)

The print head is lifted during label feed and the ribbon is stopped.

7 Print roller removal

It can be easily removed or inserted in the cases of cleaning or wear.

8 Simple replacement of materials

Label materials are inserted until lateral stop. The print head and wipe-down rollers are locked by levers.

9 Label sensor

A gap sensor or a reflective sensor position the imprint precisely on the label and detect the end of the material.

10 Material backfeed

After a label has been peeled off, the next one can be retracted to behind the print line. By this, the whole label can be printed and adhesive leaking is avoided during a longer pause. In case sensitive materials are processed and to prevent the ribbon from wrinkling, the print head can be lifted.

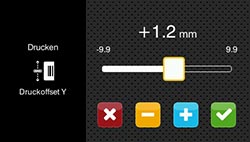

Imprint accuracy

The smaller a label, the higher are the requirements on the imprint accuracy. With the help of the adjustable slip correction, print offset can be reduced by ±0.2 mm.

Operation panel

Operating the device is intuitive and simple with the help of self-explanatory symbols to configure settings.

1 LED signal: Power ON

2 Status bar: data reception, record data stream, ribbon pre-warning, SD memory card / USB memory stick plugged in, WLAN, Ethernet, USB slave, time

3 Printer status: Ready, Pause, number of labels printed in a print job, label in peel-off position, awaiting external start signal

4 USB slot to connect the Service Key or a memory stick, in order to transfer data to the IFFS memory

5 Operation

Print label

Print label

Jump to menu

Jump to menu

Reprint last label

Reprint last label

Interrupt and continue print job

Interrupt and continue print job

Stop and delete all print jobs

Stop and delete all print jobs

Label feed

Label feed

Setup options

Print position Y

Print parameters

Print speeds

Depending from the orientation of assembly, display is either in landscape or portrait mode.

Printer rotated by 90°

Video tutorials

External operation panel

If the operation panel of a printer cannot be accessed, an additional external one can be plugged.

Same functionality as on the printer

Landscape or portrait mode

Operability as desired on the external operation panel or on the printer

Printer connectivity: USB 2.0 Hi-Speed device

1 LED: Power ON

2 USB slot to plug a service key or a memory stick, to transfer data to the IFFS memory

3 Connecting USB cable for power supply cab provides specified cables. Lengths are 1.8 m to 16 m.

SOTI Connect software enables label printers be configured and managed centrally.

The control panel of our printers can be operated in over 30 languages

typical

typical  standard

standard  option

option

| Print module | PX Q4.3 | PX Q4 | PX Q6.3 | |||

|---|---|---|---|---|---|---|

| Printing method Thermal transfer |  |

|

|

|

|

|

| Printing method Thermal direct |  |

|

- | - |  |

|

| Printable resolution dpi | 203 | 300 | 300 | 600 | 203 | 300 |

| Print speed up to mm/s | 300 | 300 | 300 | 150 | 250 | 250 |

| Print width up to mm | 104 | 108.4 | 105.7 | 105.7 | 168 | 162.6 |

| Print length up to mm | 13,500 | 6,000 | 6,000 | 1,500 | 9,000 | 4,000 |

| Direction of label transfer | L to the left or R to the right | |||||

| Print distance to locating edge for L and R mm | 1 | 1 | 1 | 1 | 1 | 1 |

| Print distance to locating edge with automatic saving L and R mm | 3.2/2.6 | 1/0.4 | 2/2 | 2/2 | 1.2/1.2 | 3.9/3.9 |

| Material | ||||||

| Labels | Paper, plastics such as PET, PE, PP, PI, PVC, PU, acrylate, Tyvec | |||||

| Labels1) Width mm | 10 - 116 | 10 - 116 | 50 - 174 | |||

| Labels1) Height without backfeed from mm | 6 | 6 | 12 | |||

| Labels1) Height with backfeed from mm | 12 | 12 | 25 | |||

| Labels1) Thickness up to mm | 0.60 | 0.60 | 0.60 | |||

| Liner material Width mm | 16 - 120 | 16 - 120 | 50 - 178 | |||

| Liner material Thicknessmm | 0.03 - 0.16 | |||||

| Ribbon2) Ink side | outside or inside | |||||

| Ribbon2) Roll diameter up to mm | 90 | |||||

| Ribbon2) Core diameter mm | 25.4 | |||||

| Ribbon2) Variable length up to m | 600 | |||||

| Ribbon2) Width mm | 25 - 114 | 25 - 114 | 50 - 170 | |||

| Ribbon2) Automatic saving |  |

|

|

|||

| Print module dimensions and weights | ||||||

| Width x Height x Depth mm | 245 x 300 x 333 | 245 x 300 x 393 | ||||

| Weight kg | 11.5 | 12 | ||||

| Label sensor with position indication | ||||||

| Gap sensor for | labels, punch marks or print marks and end of material | |||||

| Reflective sensor reflex from below for | print marks on non-transparent liner materials and end of material | |||||

| Distance of sensor to locating edge mm | 4 - 60 | 4 - 60 | 4 - 60 | |||

| Material passage mm | 2 | |||||

| Electronics | ||||||

| Processor 32 bit clock rate MHz | 800 | |||||

| Main memory (RAM) MB | 256 | |||||

| Data memory (IFFS) MB | 50 | |||||

| Slot to connect a SD memory card (SDHC, SDXC) |  |

|||||

| Battery for time and date, real-time clock |  |

|||||

| Data memory when power is switched off (e.g. serial numbering) |  |

|||||

| Interfaces | ||||||

| RS232C 1,200 to 230,400 baud/8 bit |  |

|||||

| USB 2.0 Hi-speed device to connect a PC |  |

|||||

| Ethernet 10/100 Mbit/s | LPD, RawIP printing, SOAP webservice, OPC UA, WebDAV, DHCP, HTTP/HTTPS, FTP/FTPS, TIME, NTP, Zeroconf, SNMP, SMTP, VNC | |||||

| 2 x USB host on the control panel, 2 x USB host on the back of a unit |

Service Key, USB stick, USB WLAN stick, USB WLAN stick with a rod antenna, keyboard, barcode scanner, external control panel | |||||

| Digital I/O interface 24 VDC with 8 inputs and 9 outputs |  |

|||||

| Digital I/O interface 5 VDC with 5 inputs and 6 outputs |  |

|||||

| 2-Port Ethernet Switch 10/100 Mbit/s |  |

|||||

| Operating data | ||||||

| Power supply | 100-240 VAC, 50/60 Hz, PFC | |||||

| Power consumption | Standby < 10 W / typical 100 W / max. 200 W | |||||

| Temperature / humidity Operation | +5 - 40°C / 10 - 85 %, not condensing | |||||

| Temperature / humidity Stock | 0 - 60°C / 20 - 85 %, not condensing | |||||

| Temperature / humidity Transport | –25 - 60°C / 20 - 85 %, not condensing | |||||

| Approvals | CE, UKCA, FCC Class A, ICES-3, cULus, CB, RCM | |||||

- Limitations may apply to small labels, thin materials or strong adhesives. Critical applications need to be tested.

- The ribbon should at least correspond with the width of the liner material.

For more technical data please read the product brochure (PDF)

SOTI Connect software enables label printers be configured and managed centrally.

The control panel of our printers can be operated in over 30 languages

Accessorial products are plugged or screwed to a printer by the customer.

| 1.1 | 1.2 | 1.3 | ||

| Pos | Designation | PX Q4.3 | PX Q4 | PX Q6.3 |

|---|---|---|---|---|

| 2.1 | SD memory card |  |

|

|

| 2.2 | USB memory stick |  |

|

|

| 2.3 | USB WLAN stick |  |

|

|

| 2.4 | USB WLAN stick including a rod antenna |  |

|

|

| 2.6 | I/O interface connector SUB-D, 25 pins |  |

|

|

| 2.7 | I/O interface connector SUB-D, 15 pins |  |

|

|

| 2.8 | External operation panel |  |

|

|

| Connecting USB cable |  |

|

|

|

| 2.9 | Label selection - I/O box |  |

|

|

| 2.10 | Connecting RS232 C cable |  |

|

|

| 2.11 | Interface cover unit |  |

|

|

Device functionality and compliance with CE standards are only guaranteed using accessories provided or recommended by cab.

Options

are parts or units to perform special functions. They are assembled to a printer in addition to or instead of standards. If order implies options be assembled ex factory, the part numbers of such printers and options are added by .250. Options delivered separately are added by .001.

| 1.1 | 1.2 | 1.3 | ||||

| Pos | Designation | PX Q4.3 | PX Q4 | PX Q6.3 | .250 | .001 |

|---|---|---|---|---|---|---|

| 3.1 | Automatic ribbon saving |  |

|

|

|

- |

| 3.2 | Print roller DRS |  |

|

|

|

|

| 3.3 | Digital I/O interface 24 VDC |  |

|

|

|

|

| 3.4 | Digital I/O interface 5 VDC |  |

|

|

|

|

| 3.5 | 2 port Ethernet Switch 10/100 Mbit/s |  |

|

|

|

|

| 3.6 | Interface for plugging an external label sensor |  |

|

|

|

|

Automatic ribbon saving

Use is recommended in cases of at least 60 mm unprinted area on a label. While labels are fed, the print head is lifted and the ribbon stopped, resulting in less material consumption.

Print roller DRS

providing a silicone coating. Product life is extra long, taken a higher print offset into account on a label.

providing a silicone coating. Product life is extra long, taken a higher print offset into account on a label.Digital I/O interface 24 VDC

25 pin SUB-D socket connector

Digital I/O interface 5 VDC

15 pin SUB-D socket connector

2 port Ethernet Switch 10/100 Mbit/s

to connect another terminal device in a joint network. Signals are looped through

to connect another terminal device in a joint network. Signals are looped throughInterface for plugging an external label sensor

M12 plug, 5 pins, a-coded

M12 plug, 5 pins, a-codedPlug-compatible with CEON and other sensors based on

PNP and 24 V

Documentation

-

Catalogs

-

Title Format Version Last change Language PX Q

PDF - 3.27 MB 05/2025 26/05/2025 English Overview Product Marking

PDF - 6.61 MB 05/2025 15/05/2025 English UHF RFID label printers

PX Q | HERMES Q | XD Q | SQUIXPDF - 860 KB 03/2025 18/03/2025 English

-

-

Assembly Instructions

-

Title Format Version Last change Language Assembly Instructions PX Q

PDF - 1.78 MB 05/2025 28/05/2025 English -

Other languages

-

Title Format Version Last change Language Instrukcja montażu PX Q

PDF - 2.20 MB 05/2025 28/05/2025 Polski Istruzioni di montaggio PX Q

PDF - 2.17 MB 05/2025 28/05/2025 Italiano Montageanleitung PX Q

PDF - 1.78 MB 05/2025 28/05/2025 Deutsch Montagehandleiding PX Q

PDF - 2.15 MB 05/2025 28/05/2025 Nederlands Montavimo instrukcija PX Q

PDF - 2.17 MB 05/2025 28/05/2025 Lietuvių Monteringsanvisning PX Q

PDF - 2.18 MB 05/2025 28/05/2025 Svensk Monteringsanvisning PX Q

PDF - 2.13 MB 05/2025 28/05/2025 Norsk Monteringsvejledning PX Q

PDF - 2.13 MB 05/2025 28/05/2025 Dansk Návod k montáži PX Q

PDF - 2.20 MB 05/2025 28/05/2025 Čeština Návod na montáž PX Q

PDF - 2.18 MB 05/2025 28/05/2025 Slovenský Notice d'assemblage PX Q

PDF - 2.18 MB 05/2025 28/05/2025 Français Szerelési útmutató PX Q

PDF - 2.18 MB 05/2025 28/05/2025 Magyar Upute za montažu PX Q

PDF - 2.21 MB 05/2025 28/05/2025 Hrvatski Οδηγίες συναρμολόγησης PX Q

PDF - 2.22 MB 05/2025 28/05/2025 ελληνικά Керівництво з монтажу

PDF - 2.24 MB 05/2025 28/05/2025 Українська

-

-

-

Interface Descriptions

-

Information on the interface type can be found on the original cab packaging, in the printer status report after installation or as a label next to the SUB-D connection.

Title Format Version Last change Language Interface Description I/O 24V25-2 and I/O 24V25-3

PDF - 278 KB 05/2025 16/05/2025 English Interface Description I/O 5V15-2 and I/O 5V15-3

PDF - 202 KB 05/2020 06/02/2024 English Interface Description I/O 24V25-4

PDF - 278 KB 05/2025 16/05/2025 English -

Other languages

-

Title Format Version Last change Language Description de l'interface I/O 24V25-4

PDF - 301 KB 05/2025 16/05/2025 Français Description des interfaces I/O 24V25-2 et I/O 24V25-3

PDF - 302 KB 05/2025 16/05/2025 Français Description des interfaces I/O 5V15-2 et I/O 5V15-3

PDF - 583 KB 05/2020 01/03/2023 Français Schnittstellenbeschreibung I/O 24V25-2 und I/O 24V25-3

PDF - 265 KB 05/2025 16/05/2025 Deutsch Schnittstellenbeschreibung I/O 24V25-4

PDF - 268 KB 05/2025 16/05/2025 Deutsch Schnittstellenbeschreibung I/O 5V15-2 und I/O 5V15-3

PDF - 197 KB 05/2020 01/03/2023 Deutsch

-

-

-

Configuration Manuals

-

Title Format Version Last change Language Configuration manual cab Label Printers

from SN 14089PDF - 2.57 MB 08/2024 19/08/2024 English -

Other languages

-

Title Format Version Last change Language Konfigurationsanleitung cab-Etikettendrucker

ab SN 14089PDF - 2.60 MB 08/2024 19/08/2024 Deutsch Manuel de configuration imprimantes d'étiquettes cab

à partir du numéro de série 0014089PDF - 2.66 MB 08/2024 19/08/2024 Français

-

-

-

Programming

-

Title Format Version Last change Language Brief introduction to cab printer programming

PDF - 7.47 MB 04/2022 15/01/2025 English cab Download Converter (download.exe)

Converts image, font and database files into the JScript download data format.

Install MS Visual C++ 2010 Redistributable if not available on your system.ZIP - 9 KB 2.3 25/10/2024 – cab Remote Control

Remote control of cab systems for label printing / Fernsteuerung von cab Drucksystemen - HERMES Q, SQUIX, PX QZIP - 3.50 MB 2021/07 15/01/2025 English/Deutsch cabPROTECT - Data security in label printing

PDF - 472 KB 06/2024 20/06/2024 English Connecting cab printing systems to SAP®

CompendiumPDF - 4.45 MB 01/2025 11/02/2025 English Networked labeling with OPC UA

cab and the Smart FactoryPDF - 1.12 MB 03/2019 15/01/2025 English PLC Programmer's Guide HERMES Q, SQUIX, XD Q, PX Q

with label layouts and programming examplesZIP - 16.17 MB 06/2020 15/01/2025 English Programming Manual abc Basic Compiler

for cab printersPDF - 755 KB 11/2024 29/11/2024 English Programming Manual JScript

for SQUIX, MACH 4S, EOS2, EOS5, XC Q, XD Q, HERMES Q, PX Q, AXON1, AXON 2, A+, HERMES+, A-Series, EOS1/4, MACH4, XD, XCPDF - 4.30 MB 05/2025 23/05/2025 English ZPL Emulation with cab printers

PDF - 2.28 MB 05/2025 23/05/2025 English -

Other languages

-

Title Format Version Last change Language Anbindung von cab Drucksystemen an SAP®

KompendiumPDF - 4.55 MB 01/2025 11/02/2025 Deutsch Kurze Einführung in die cab Druckerprogrammierung

PDF - 7.50 MB 04/2022 12/04/2022 Deutsch Marquage en réseau avec OPC UA

cab et l'usine intelligentePDF - 745 KB 01/2022 23/10/2024 Français SPS Programmieranleitung HERMES Q, SQUIX, XD Q, PX Q

mit Etikettenlayouts und BeispielprogrammenZIP - 16.22 MB 06/2020 18/04/2024 Deutsch Vernetzt kennzeichnen mit OPC UA

cab und die intelligente FabrikPDF - 1.13 MB 03/2019 28/01/2021 Deutsch

-

-

-

Service Manuals

-

Title Format Version Last change Language Service Manual PX Q

PDF - 2.95 MB 05/2025 21/05/2025 English -

Other languages

-

Title Format Version Last change Language Serviceanleitung PX Q

PDF - 2.96 MB 05/2025 21/05/2025 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List PX Q

PDF - 1.13 MB 05/2025 20/05/2025 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste PX Q

PDF - 1.14 MB 05/2025 20/05/2025 Deutsch

-

-

-

Assembly Instructions Spare Parts

-

Title Format Version Last change Language 9004105 | Druckkopfwechsel / Printhead Replacement: SQUIX, HERMES Q, MACH 4S, EOS2, EOS5, PX Q, AXON1, XC Q, XD Q

PDF - 5.70 MB 06/2024 18/06/2024 English/Deutsch

-

-

Manuals Accessories

-

Title Format Version Last change Language External Operation Panel - Instructions

PDF - 274 KB 04/2023 12/04/2023 English Label File Selection Box - Input Output Box - Instructions

PDF - 329 KB 04/2023 12/04/2023 English -

Other languages

-

Title Format Version Last change Language Etikettenauswahlbox - Ein-/Ausgabebox - Betriebsanleitung

PDF - 317 KB 04/2023 12/04/2023 Deutsch Externes Bedienfeld - Betriebsanleitung

PDF - 280 KB 04/2023 12/04/2023 Deutsch Labelbox - I/O Box - Instructions d'utilisation

PDF - 330 KB 04/2023 12/04/2023 Français Panneau de commande externe - Instructions d'utilisation

PDF - 277 KB 04/2023 12/04/2023 Français

-

-

-

EU Declarations of Conformity - Accessories

-

Title Format Version Last change Language External Operation Panel - EU Declaration of Conformity

PDF - 30 KB 07/2019 02/02/2023 English -

Other languages

-

Title Format Version Last change Language Etikettenauswahlbox - Ein-/Ausgabebox - Konformitätserklärung

PDF - 30 KB 07/2019 02/12/2020 Deutsch Externes Bedienfeld - Konformitätserklärung

PDF - 30 KB 07/2019 02/12/2020 Deutsch Labelbox - I/O Box - Déclaration UE de conformité

PDF - 30 KB 07/2019 02/12/2020 Français Panneau de commande externe - Déclaration UE de conformité

PDF - 30 KB 07/2019 02/12/2020 Français

-

-

-

Case study

-

Title Format Version Last change Language Covid-19 rapid test: A combination of machines providing, labeling and packing

PDF - 771 KB 08/2020 25/08/2022 English

-

-

Safety data sheets

-

Title Format Version Last change Language Safety Data Sheet Special Cleaner for Glass and Plastic GR1N

PDF - 65 KB 08/2017 23/10/2024 English -

Other languages

-

Title Format Version Last change Language Sicherheitsdatenblatt Spezial Glasreiniger und Kunststoffreiniger GR1N

PDF - 156 KB 06/2017 25/08/2022 Deutsch Sicherheitsdatenblatt Spezial-Gummiwalzen-Reiniger WR1

PDF - 173 KB 06/2017 25/08/2022 Deutsch

-

-

3D CAD models

The files are provided in STEP format, which requires CAD software. Follow this link to download a free STP Viewer: VariCAD Viewer (External website).

Select the desired model and click on the link. A short registration follows. cab will handle your personal information as described in our Privacy statement. This information will not be accessible to any third party for marketing purposes. You will receive an email with an activation link and you can download the models.

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Here you can download firmware, drivers and software. Documentation on label software, printers programming and administration as well as integration of cab printers into SAP systems:

Label software

Software & Drivers

-

Firmware

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Firmware X4

Firmware SQUIX | EOS2 | EOS5 | MACH 4S | XD Q | XC Q | HERMES Q | PX Q | AXONZIP - 53.66 MB 5.46.4 05/06/2025 – Release Notes Firmware X4

TXT - 123 KB

TXT - 123 KB

5.00 - 5.46.4 05/06/2025 –

-

-

Firmware periphery

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Firmware I/O 24V25-2, I/O 24V25-3, I/O 5V15-2 and I/O 5V15-3

ZIP - 23 KB 3.2.0 08/04/2025 –

-

-

Drivers

-

Title Format Version Last change Language cab Linux Armv7 - 32 Bit Driver

CUPS Linux Armv7 32bit Driver RPi 2/3/4 (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab Linux Armv8(aarch64) - 64 Bit Driver

CUPS Linux Armv8 64 Bit Driver RPi 3/4 (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab Linux x86 - 32 Bit Driver

CUPS Linux Intel 32bit Driver (min. CUPS 1.2)GZ - 2.81 MB 1.46 23/10/2024 – cab Linux x86 - 64 Bit Driver

CUPS Linux Intel/AMD 64bit Driver (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab MAC OS Driver

Apple® Mac OS 10.15 - 15.4ZIP - 2.97 MB 1.46 01/04/2025 – cab MAC OS X Driver

Apple® Mac OS X 10.6 - 10.14ZIP - 5.82 MB 1.46 23/10/2024 – cab Windows Driver ARCHIV

Vista, Windows 7, Windows 8, Windows 8.1, Windows 10, Windows Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019 - 32/64 Bit CERTIFIEDZIP - 9.37 MB 5.3.03 21/02/2024 – cab Windows Driver NEW

Windows 10, Windows 11, Windows Server 2016, Windows Server 2019, Windows Server 2022 - 64Bit, requires Visual C++ 2022ZIP - 24.01 MB 1.4.1.0 24/03/2025 – cab Windows Driver NEW Release Notes

PDF - 120 KB 1.2.1.20 - 1.4.1.0 24/03/2025 –

-

-

Software

-

Title Format Version Last change Language cab Download Converter (download.exe)

Converts image, font and database files into the JScript download data format.

Install MS Visual C++ 2010 Redistributable if not available on your system.ZIP - 9 KB 2.3 25/10/2024 – cablabel S3 Demo (Free)

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 51.42 MB 1.4.0.9 30/06/2025 – cablabel S3 Lite (Free)

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 68.19 MB 1.4.0.9 26/11/2024 – cablabel S3 Print

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 57.82 MB 1.4.0.9 30/06/2025 – cablabel S3 Pro

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 68.64 MB 1.4.0.9 30/06/2025 – Database Connector

Windows 32 & 64 bitZIP - 10.93 MB 4.3.0.1 25/10/2024 – LogService

for Database ConnectorZIP - 4.15 MB 1.7.1.0 25/10/2024 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Ready to interact with machines and components of different manufacturers in industrial plants.