Laser safety housing

LSG+100E

Industrial solution that allows the marking of parts in series

The laser safety housing LSG+100E offers an industrial solution for marking component series with a marking laser XENO 4. The rugged metal design besides a large work area provides enough space to integrate both the laser beam source and an industrial PC in a 19“ rack mount.

The laser safety housing LSG+100E offers an industrial solution for marking component series with a marking laser XENO 4. The rugged metal design besides a large work area provides enough space to integrate both the laser beam source and an industrial PC in a 19“ rack mount.

The keyboard and the monitor are ergonomically assembled to a pivot arm. The operation door opens and closes electrically.

Accessories

- 4.3 PC in 4RU 19’’ rack mount

- 4.4 Monitor 23,8"

- 4.5 Standard keyboard, optical mouse

- 4.6 Keyboard with trackball

- 6.7 Extraction and filter device AF5

- 8.1 on request: Rotary table module RTM650

- 8.6 Linear axis X230

- 8.9 Linear axis Z400

- 8.10 Rotary axis D30

- 8.11 3-jaw chuck D30

- 8.15 Axis controller 2S

Setup door

The large setup door allows easily accessing the laser safety housing LSG+100E. At this, jigs may comfortably be mounted on the groove plate in the well-lit work area.

Linear axis Z400

It provides precise and fast focus adjustment. The linear axis is traversed with buttons integrated to the operation panel.

Laser safety housing LSG+100E

vergrößern

vergrößern

Video: THS4.2 Type Plate Handling

The Type Plate Handling THS4.2 offers - based on the approved laser safety housing LSG100 - a professional solution to fully automatically laser mark plates, mainly out of steel or plastics.

XENO 1 is a compact desktop system, offering little footprint and a large work area.

| 3.1 | 3.2 | |||

| Laser safety housing | LSG+100E 230 V | LSG+100E 120 V | ||

|---|---|---|---|---|

| Work area W x H x D mm | 980 x 460 x 980 | |||

| Groove plate T-slot W x D mm | 550x375 | |||

| Pitch mm | 25 | |||

| Z-Axis stroke mm | 440 | |||

| Positioning accuracy mm | 0.02 | |||

| Repetitive accuracy mm | +/- 0.02 | |||

| Traversing speed up to mm/s | 60 | |||

| Interior lighting | Low energy light bulb | |||

| Operating door | electrical opening / closing | |||

| Opening/closing time s | <2 | |||

| For plano-spherical lens type | 100.1 | 160.1 | 254.1 | 420.1 |

| Marking field mm | 69x69 | 112x112 | 180x180 | 290x290 |

| Working distance mm | 141 ± 4 | 202 ± 8 | 302 ± 8 | 541 ± 20 |

| Workpiece height up to mm | 60-490 | 430 | 330 | 90 |

| Workpiece weight max. kg | 50 | |||

| Dimensions and weight | ||||

| W x H x D mm | 1,000 x 2,280 x 1,120 | |||

| Laser protection window W x H mm | 200 x 100 | |||

| Machine stands Ø mm | 80 | |||

| Suction nozzle Ø mm | 50 | |||

| Rack mount for marking laser FL+ and PC | 4RU 19" | |||

| Weight kg | 395 | |||

| Operating data | LSG+100E 230 V | LSG+100E 120 V | ||

| Operating Voltage/frequency VAC/Hz | 220-240/50 | 100-140/60 | ||

| Power | ON/OFF | |||

| Laser safety class EN60825-1 | Class 1 | |||

| Approval | CE | |||

| Control panel | ||||

| LED indicators | Power Emission Marking Ready Error |

|||

| Push buttons illuminated | Control ON/OFF Focus finder ON/OFF Extraction ON/OFF Interior light ON/OFF Start Z-axis UP/DOWN X-axis LEFT/RIGHT Rotary axis LEFT/RIGHT OPEN/CLOSE door Reserve |

|||

| Switch | E-Stop | |||

| Key switch | automatic/manual | |||

| Monitoring | ||||

| Safety circuits | closed | |||

| Collective error | Marking laser Extraction device |

|||

| Interfaces | ||||

| Interlock/E-Stop FL+ | ||||

| Remote FL+ | ||||

| Digitale I/O FL+ | ||||

| Stepper motor Z-axis, X-axis, rotary axis | ||||

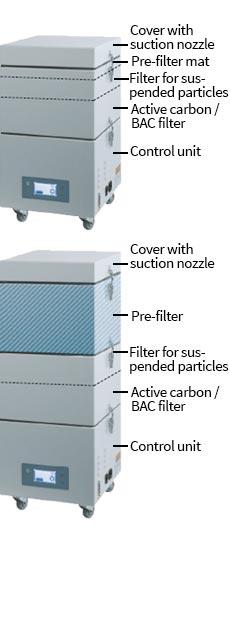

| Extraction and filter device AF5 | ||||

Documentation

-

Catalogs

-

Title Format Version Last change Language Laser marking systems

PDF - 2.97 MB 10/2024 23/10/2024 English Overview Product Marking

PDF - 6.61 MB 05/2025 15/05/2025 English

-

3D CAD models

The files are provided in STEP format, which requires CAD software. Follow this link to download a free STP Viewer: VariCAD Viewer (External website).

Select the desired model and click on the link. A short registration follows. cab will handle your personal information as described in our Privacy statement. This information will not be accessible to any third party for marketing purposes. You will receive an email with an activation link and you can download the models.

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Software & Drivers

-

Software

-

Title Format Version Last change Language cabLaseEditor (TCP/IP)

ZIP - 153.58 MB 5.3.4.6 i01 18/09/2024 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader