PCB separator

MAESTRO 4S

Stress-free separation of pre-scored PCBs

MAESTRO 4S separates both small and large PCBs quickly and economically without stress.

Key features:

- Blade distance to be entered on the operation panel is set motor-driven.

- Up to nine programs to be stored

- Separation length to be continuously adjusted via limit switches

- In terms of a preventive blade maintenance, the cutting performance is displayed.

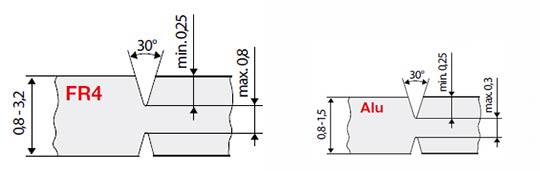

Material: FR4 1.5 mm

Residual thickness approx. 0.6 mm

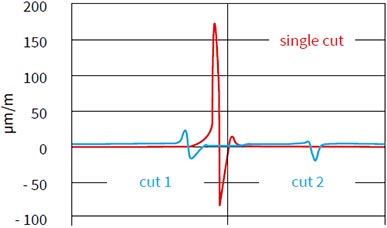

By traversing the milled groove once, tensile and compressive stresses can cause damage to sensitive components located close to the groove. A second traverse and simultaneous readjustment of the blade distance already reduces stresses considerably. The quality of the assembled PCBs improves significantly.

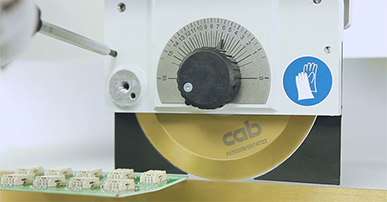

Dial gauge

In order to separate without stress and to achieve a long service life, the circular and linear blades have to be guided along the entire separation. The dial gauge setting and regularly checking the parallelism is assembled to the carriage.

Separating aluminum

To separate aluminum with MAESTRO 4S, special adjustment is needed for the standard circular blade. For information see the operator's manual

Aluminum PCBs are manufactured in various alloys. Sample PCBs added to a request help with adjusting the circular blade and optimizing the cutting geometry.

|

Component height

Outside dimensions increased |

|

|

|

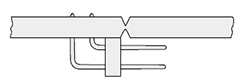

The milled groove may be interrupted by cutouts. |

||

|

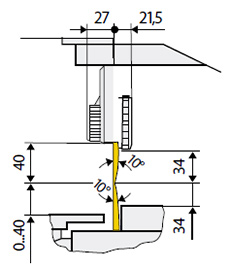

Protruding components need a recessed linear blade. |

|

|

Adjustment of the upper guide

In this video tutorial we show you step by step how to adjust the upper guides and the cutting length on MAESTRO 4S.

| Technical data | 4S/450 | 4S/600 |

|---|---|---|

| Separation method | Component side: Circular blade Solder side: Linear blade |

|

| Operation | path-optimized, motor-driven | |

| Separation speed | 300, 500 mm/s, to be switched | |

| Materials | FR4, aluminum | |

| Component height | Component/solder side up to 34 mm | |

| Separation length | up to 450 mm | up to 600 mm |

| Support table depth | 200 mm | |

| Programming | ||

| Start | Traverse to initial position | |

| Programs | 9 | |

| Separation steps | 1 - 5 | |

| Blade distance | 0.9 mm - 0.05 mm | |

| Key switch button | Unlock program selection | |

| Performance display | up to 99 km | |

| DEL | Step reset | |

| Power switch | ON / OFF | |

| Foot switch | START separation | |

| Safety switch | E-stop | |

| Power supply | 100 - 240 VAC, 50/60 Hz | |

| Emission sound pressure level | LpA < 70 dB (A) | |

| Temperature/humidity: Operation Temperature/humidity: Stock Temperature/humidity: Transport |

+ 10 - 35°C / 10 - 85 % not condensing 0 - 60°C / 20 - 80 % not condensing – 25 - 60°C / 20 - 80 % not condensing |

|

| Width x Height x Depth | 702 x 434 x 425 mm | 852 x 434 x 425 mm |

| Weight | 38 kg | 46 kg |

| Approvals | CE, FCC Class A | |

For more technical data please read the product brochure (PDF)

Conveyor belt

to deposit separated PCBs individually and further transport them aside. The speed adapts to the size of the PCB. Incoming PCBs are detected by a light barrier and the belt stops.

| Technical data | 450 | 600 |

|---|---|---|

| Conveyor belt material | antistatic | |

| Direction of movement | to the right | |

| Belt speed | 5, 6, 7, 8, 9 m/min | |

| Light barrier | to be activated to stop the belt moving | |

| Vertical distance to the linear blade | 5 - 17 mm | |

| PCB depth | up to 200 mm | |

| Belt width | 170 mm | |

| Length | 1,200 mm | 1,350 mm |

| Power supply | 100 - 240 VAC, 50/60 Hz | |

| Temperature / humidity Operation Temperature / humidity Stock Temperature / humidity Transport |

+ 10 - 35°C / 10 - 85 % not condensing 0 - 60°C / 20 - 80 % not condensing – 25 - 60°C / 20 - 80 % not condensing |

|

| Weight | 14 kg | |

| Approvals | CE, FCC Class A | |

Documentation

-

Catalogs

-

Title Format Version Last change Language Products for the Electronic Industry

PCB Separators and PCB MagazinesPDF - 6.31 MB 10/2022 16/04/2025 English

-

-

Operation Manuals

-

Title Format Version Last change Language Operator's Manual MAESTRO 4S

PDF - 1.19 MB 05/2019 29/05/2019 English Cutting of aluminium PCB‘s via a roller blade FR4

Modification Instruction MAESTRO 4SPDF - 264 KB – 03/11/2014 English/Deutsch -

Other languages

-

Title Format Version Last change Language 操作手册 分板机 4S

PDF - 1.83 MB 02/2016 26/11/2020 简体字 操作手冊 分板機 4S

PDF - 2.11 MB 02/2016 26/11/2020 繁體字 Návod k obsluze Separátor MAESTRO 4S cs

PDF - 1.20 MB 05/2019 25/11/2020 Čeština Handleiding PCB-separator MAESTRO 4S nl

PDF - 1.18 MB 05/2019 25/11/2020 Nederlands Manuel d'utilisation Séparateur de cartes MAESTRO 4S fr

PDF - 1.19 MB 05/2019 25/11/2020 Français Bedienungsanleitung Nutzentrenner MAESTRO 4S de

PDF - 1.20 MB 05/2019 26/11/2020 Deutsch Istruzioni per l'uso Depannellizzatore Maestro 4S it

PDF - 1.17 MB 05/2019 25/11/2020 Italiano Instrucciones de servicio Separador de placas PCB MAESTRO 4S es

PDF - 1.19 MB 05/2019 26/11/2020 Español

-

-

-

Service Manuals

-

Title Format Version Last change Language Service Manual MAESTRO 4S

incl. Spare Parts ListPDF - 3.15 MB 12/2019 11/12/2019 English

-

-

Spare Parts

-

Title Format Version Last change Language Service Manual MAESTRO 4S

incl. Spare Parts ListPDF - 3.15 MB 12/2019 11/12/2019 English

-

-

Assembly Instructions Spare Parts

-

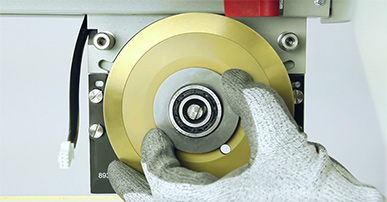

Title Format Version Last change Language 9008620 | MAESTRO 2, MAESTRO 2M, MAESTRO 3, MAESTRO 4M, MAESTRO 4S, MAESTRO 3/70, MAESTRO 4M/70, MAESTRO 6/601.70; Rollmesser oben / Circular upper blade

PDF - 148 KB – 29/05/2024 English/Deutsch 9008622 | MAESTRO 3, MAESTRO 4M, MAESTRO 3/600, MAESTRO 4M/600, MAESTRO 4M clean: Linearmesser / Linear blade

PDF - 203 KB – 29/05/2024 English/Deutsch

-

-

cab Video Tutorials

-

Title Format Version Last change Language Adjustment of the upper guides and cutting length on MAESTRO 4S

cab video tutorial– 12/2015 27/02/2017 English Changing the lower blade on MAESTRO 4S

cab video tutorial– 12/2015 27/02/2017 English Changing the upper blade on MAESTRO 4S

cab video tutorial– 12/2015 27/02/2017 English

-

-

Manuals Accessories

-

Title Format Version Last change Language Operator's Manual Conveyor Belt

PDF - 571 KB 10/2017 12/10/2017 English

-

-

Spare Parts Accessories

-

Title Format Version Last change Language Spare Parts List Conveyor Belt

PDF - 3.12 MB 08/2010 06/10/2014 English

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader