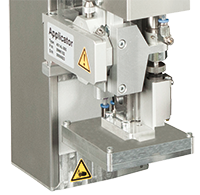

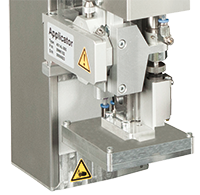

Stroke applicators 4014, 4016

Labels can be applied in real time from all sides to packages

The type of pad defines whether a package has to be at rest or can be in motion at the time a label is applied.

The pad locates in front of the peel-off plate. It picks up a label while it is being printed. The label is transferred to a package with the help of a stroke cylinder. The package is detected by a sensor and the pad returned to its initial position. The length of the stroke cylinder defines the maximum distance of a package to the peel-off plate.

Tamp-on pad

Tamp-on pad

Labels are precisely tamped on plane surfaces. Recessed levels are possible as well.

Universal pad

Universal pad

Labels can be tamped on plane surfaces. Drilled holes are provided in gaps of 5 mm to suck a label. The holes are covered by a sliding foil, but can be opened according to the size of a label using a punching tool. Delivery includes two extra foils.

Tamp-on pad, spring-mounted

Tamp-on pad, spring-mounted

Labels can be applied to surfaces inclined by a maximum of 15°. Heights witin the area of a label may vary by 10 mm at most.

Universal pad, spring-mounted

Universal pad, spring-mounted

Labels can be applied to surfaces inclined by a maximum of 15°. Heights in the area of a label may vary by 10 mm at most. To suck a label, drilled holes are provided in gaps of 5 mm and covered by a sliding foil. Delivery includes two extra foils.

"In terms of technical expertise we felt at home with cab from the beginning."

Klaus-Dieter Schrader, Head of Systems Engineering at the central warehouse of ROSSMANN

Hermes+ Systems with Applicator 4016 provide the marking of potentially hazardous goods at the ROSSMANN central warehouse

Blow-on pad

Blow-on pad

It benefits when labels have to be applied to sensitive surfaces or packages in motion. Labels are blown on by a blast of air. Stroke cylinder adjustment enables bridging distances of 5 to 10 mm to the surface of a package.

Roll-on pad

Roll-on pad

Labels are rolled on plane surfaces while these packages are in motion.

Corner-wrap pad

Corner-wrap pad

Labels are applied to a package on two sides adjacent to one another. One half of a label is applied to the top of a package. Then the other half of the label is rolled on.

Designed for fully-automated print and apply processes in production lines.

Hermes+ systems label hazardous goods at ROSSMANN‘s central warehouse

The device is designed to use on a cab printer of the HERMES Q and Hermes+ series.

| Technical data | Tamp-on pad | Universal pad | Tamp-on pad, spring-mounted |

Universal pad, spring-mounted |

|---|---|---|---|---|

| 4014, 4016 L/R 11 F | 4014 L/R 1100 | 4014, 4016 L/R 3100 | 4014 L/R 3100 | |

| Label widths operating a HERMES Q4/Q4.3 mm Label widths operating aHERMES Q6.3 mm |

20 - 114 | 75 / 90 | 80 - 114 | 116 / 116 |

| 50 - 174 | - | 80 - 174 | - | |

| Label heights operating a HERMES Q4/Q4.3 mm Label heights operating a; HERMES Q6.3 mm |

20 - 210 | 60 / 90 | 80 - 210 | 102 / 152 |

| 25 - 210 | - | 80 - 210 | - | |

| State of a package at the moment at rest a label is applied |

|

|||

| Label applications from the top from below from the side |

|

|||

|

||||

|

||||

| Package heights variable |  |

|||

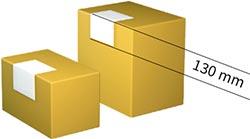

| Distance of a package to the bottom of the unit using a cylinder stroke of 200 up to mm cylinder stroke of 300 up to mm cylinder stroke of 400 up to mm |

135 |

135 |

130 |

130 |

| 235 | 235 | 230 | 230 | |

| 335 | 335 | 330 | 330 | |

| Depth of a pad immersing F1) up to mm | 120 | - | - | - |

| Weight of applicator using a cylinder stroke of 200packaging excluded kg cylinder stroke of 300packaging excluded kg cylinder stroke of 400packaging excluded kg |

4014 5 |

4016 5 |

||

| 5 | 5.5 | |||

| 7 | 7.5 | |||

| Consumption of power W max. | 15 | |||

| Compressed air bar | 4.5 | |||

| Cycle rate2) labels/min approx. | 25 | |||

- On the cover HERMES Q2/Q4/Q4.3 cut-out dimension F standard 60 mm, optional 100 mm, on r equest up to 120 mm

On the cover HERMES Q6.3 cut -out dimension F standard 25 mm, on request up to 120 mm - calculated using a stroke of 100 mm below the unit, labels 100 mm high, a print speed of 100 mm/s

| Technical data | Blow-on pad | Roll-on pad | Corner-wrap pad |

|---|---|---|---|

| 4014 L/R 2100 | 4014. 4016 L/R 4100 | 4014 L/R 5100 | |

| Label widths operating a HERMES Q4/Q4.3 mm Label widths operating a HERMES Q6.3 mm |

20 - 114 | 25 - 114 | 20 - 114 |

| provided on request | 50 - 174 | - | |

| Label heights operating a HERMES Q4/Q4.3 mm Label heights operating a HERMES Q6.3 mm |

20 - 100 | 80 - 250 | 60 - 210 |

| provided on request | 80 - 250 | - | |

| State of a package at the moment at rest a label is applied in motion |

|

- |  |

|

|

- | |

| Label applications from the top from below from the side |

|

|

|

|

|

- | |

|

|

- | |

| Product heights uniform variable |

|

- | - |

| - |  |

|

|

| Distance of a package to the bottom of the unit using a cylinder stroke of 200 up to mm cylinder stroke of 300 up to mm cylinder stroke of 400 up to mm |

140 |

160 |

100 |

| 240 | 260 | 200 | |

| 340 | 360 | 300 | |

| Weight of applicator packaging excluded kg | See above | ||

| Consumption of power W max. | 15 | ||

| Compressed air bar | 4.5 | ||

| Cycle rate1) labels/min approx. | 25 | 20 | 20 |

Video: Hermes+ Applicator 4014 (roll-on pad)

Powered by YouTube. See all cab videos: cab Channel auf YouTube.

Other formats

- Hermes+ Applicator 4014 (roll-on pad) (MPEG-4; 6,6 MB)

Video: Hermes+ with stroke applicator 4014 and blow pad

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- Hermes+ with stroke applicator 4014 and blow pad (MPEG-4, 80,6 MB)

- Hermes+ with stroke applicator 4014 and blow pad (WMV, 50,8 MB)

Case study: Hermes+ systems label hazardous goods at ROSSMANN‘s central warehouse

Powered by YouTube. See all cab videos: cab Channel auf YouTube.

Video: Hermes+ with stroke applicator 4014 and blow pad

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- Hermes+ with stroke applicator 4014 and blow pad (MPEG-4, 80,6 MB)

- Hermes+ with stroke applicator 4014 and blow pad (WMV, 50,8 MB)

Video: Hermes+ with stroke applicator 4016 and universal pad

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- Hermes+ with stroke applicator 4016 and universal pad (MPEG-4, 2,3 MB)

- Hermes+ with stroke applicator 4016 and universal pad (WMV, 7,2 MB)

cab Video Tutorial: Assembly of the applicator 4016 in combination with the printer Hermes+ 6

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- cab Video Tutorial: Assembly of the Applicator 4016 in Combination with the Printer Hermes+ 6 (WMV, 90,7 MB)

- cab Video Tutorial: Assembly of the Applicator 4016 in Combination with the Printer Hermes+ 6 (MPEG-4, 16,7 MB)

Download players:

- For WMV: Windows Media Player

- For MPEG-4: VLC Player

Documentation

-

Catalogs

-

Title Format Version Last change Language HERMES Q

PDF - 6.09 MB 09/2024 12/12/2024 English

-

-

Assembly Instructions

-

Title Format Version Last change Language Assembly Instructions Stroke Applicator 4014/4016

PDF - 813 KB 08/2019 10/08/2022 English -

Other languages

-

Title Format Version Last change Language Bedieningshandleiding Applicator 4014/4016 nl

PDF - 682 KB 02/2019 10/08/2022 Nederlands Käyttöopas Aplikaattori 4014/4016 fi

PDF - 634 KB 02/2019 10/08/2022 Suomi Instrukcja obsługi Aplikator 4014/4016 pl

PDF - 713 KB 02/2019 10/08/2022 Polski Istruzioni per l'uso Applicatore 4014/4016 it

PDF - 679 KB 02/2019 10/08/2022 Italiano Manual de instrucciones Aplicador de presión 4014/4016 es

PDF - 687 KB 02/2019 10/08/2022 Español Montageanleitung Hub-Applikator 4014/4016

PDF - 827 KB 08/2019 10/08/2022 Deutsch Notice d'assemblage applicateur 4014/4016

PDF - 1.40 MB 08/2019 10/08/2022 Français

-

-

-

Service Manuals

-

Title Format Version Last change Language Service Manual Stroke Applicator 4014/4016 - from SN 9742

PDF - 6.72 MB 10/2022 20/10/2022 English Service Manual Stroke Applicator 4014/4016 - up to SN 9741

incl. Spare Parts ListPDF - 6.66 MB 06/2017 09/12/2020 English -

Other languages

-

Title Format Version Last change Language Manuel de service Applicateur 4014/4016 - à partir du numéro de série 0009742

PDF - 7.20 MB 10/2022 20/10/2022 Français Manuel de service Applicateur 4014/4016 - jusqu'au numéro de série 0009741

incluant les pièces détachéesPDF - 6.71 MB 06/2017 09/12/2020 Français Serviceanleitung Hub-Applikator 4014/4016 - ab SN 9742

PDF - 6.76 MB 10/2022 20/10/2022 Deutsch Serviceanleitung Hub-Applikator 4014/4016 - bis SN 9741

inkl. ErsatzteillistePDF - 6.71 MB 06/2017 09/12/2020 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List Stroke Applicator 4014/4016 - from SN 9742

PDF - 1.03 MB 01/2023 03/02/2023 English Service Manual Stroke Applicator 4014/4016 - up to SN 9741

incl. Spare Parts ListPDF - 6.66 MB 06/2017 09/12/2020 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste Hub-Applikator 4014/4016 - ab SN 9742

PDF - 1.03 MB 01/2023 03/02/2023 Deutsch Manuel de service Applicateur 4014/4016 - jusqu'au numéro de série 0009741

incluant les pièces détachéesPDF - 6.71 MB 06/2017 09/12/2020 Français Serviceanleitung Hub-Applikator 4014/4016 - bis SN 9741

inkl. ErsatzteillistePDF - 6.71 MB 06/2017 09/12/2020 Deutsch

-

-

-

Assembly Instructions Spare Parts

-

Title Format Version Last change Language Montageanleitung Neubekleben Stempel / Assembly Instruction Re-gluing Stamp

PDF - 822 KB 08/2024 23/08/2024 English/Deutsch

-

-

Case study

-

Title Format Version Last change Language DataMatrix code printed on canister caps; Traceable crop protection with the help of Hermes+ at Barclay Chemicals, Ireland

PDF - 1.78 MB 01/2019 29/01/2019 English Hermes+ systems label hazardous goods at ROSSMANN‘s central warehouse

37,000 labeling operations a dayPDF - 1.34 MB 12/2015 09/05/2019 English

-

-

Safety data sheets

-

Title Format Version Last change Language Safety Data Sheet Special Cleaner for Glass and Plastic GR1N

PDF - 65 KB 08/2017 23/10/2024 English Safety Data Sheet Special Rubber Cleaner WR1

PDF - 76 KB 12/2017 23/10/2024 English -

Other languages

-

Title Format Version Last change Language Sicherheitsdatenblatt Spezial Glasreiniger und Kunststoffreiniger GR1N

PDF - 156 KB 06/2017 25/08/2022 Deutsch Sicherheitsdatenblatt Spezial-Gummiwalzen-Reiniger WR1

PDF - 173 KB 06/2017 25/08/2022 Deutsch

-

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

We offer Hermes Q 3D CAD models with different applicators in stp file format.

Well-trained cab service engineers worldwide support in the maintenance and repair of the devices.