Vacuum belt applicators 5326/5426

For real-time labeling on packaging or products in motion

vergrößern

vergrößern5326C

vergrößern

vergrößern5426C

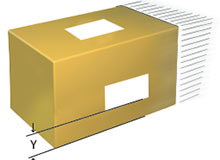

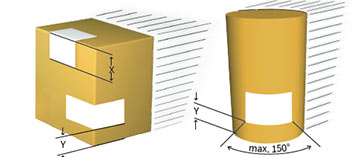

Labels may be applied on the product from all sides on a flat surface, on a cylinder resp. by corner wrap labeling.

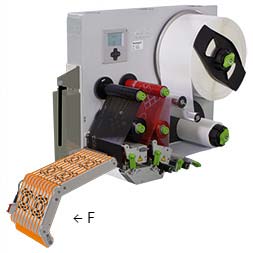

The vacuum belt applicator is positioned in front of the peel-off plate. The printed label is moved to the labeling position via vacuum belt and applied on the packaging via external signal. Printing and labeling may be done simultaneously.

Especially for two-color printing and applying in real-time.

| Technical data | Vacuum belt applicator | |

|---|---|---|

| 5326C | 5426C | |

| Labeling | on plane surfaces | on cylindric surfaces and corner-wrap |

| Dispensing direction | Left | Left |

| Label width mm | 46-174 | 46-174 |

| Label height mm | 80-356 | 80-356 |

| Product during labeling in motion |  |

|

| Labeling on the product from top |  |

|

| Labeling on the product from below |  |

- |

| Labeling on the product from the side |  |

|

| Product height | Steady | Steady |

| Product speed max. m/s | 0.5 | 0.3 |

| Distance between one product and the next min. m | 1.0 | 0.6 |

| Weight of applicator packaging excluded kg | not specified | 9 |

| Consumption of power W max. | 90 | 90 |

| Stability at application level F=mm | - | 10 N x factor 3 |

| Corner wrap labeling X max. mm | - | 180 |

| Labeling on a cylinder diameter min. mm | - | Depending on the label length |

| Vacuum belt speed1) mm/s | 100-500 | 100-300 |

| Cycle time2) max. labels/min. | 15 | 15 |

| Label distance to conveyor belt when labeling from the side Y min. mm |

20 | 20 |

Documentation

-

Catalogs

-

Title Format Version Last change Language Hermes C

PDF - 3.03 MB 01/2025 31/01/2025 English

-

-

Assembly Instructions

-

Title Format Version Last change Language Assembly Instructions Vacuum-Belt Applicator 5326C

PDF - 953 KB 12/2019 02/03/2021 English Assembly Instructions Vacuum-Belt Applicator 5426C

PDF - 1.77 MB 12/2019 02/03/2021 English -

Other languages

-

Title Format Version Last change Language Instrucciones de montaje Aplicador con cinta de aspiración 5326C

PDF - 1.07 MB 12/2019 21/04/2023 Español Montageanleitung Saugband-Applikator 5326C

PDF - 957 KB 12/2019 02/03/2021 Deutsch Montageanleitung Saugband-Applikator 5426C

PDF - 1.75 MB 12/2019 02/03/2021 Deutsch Notice d'assemblage Applicateur 5326C

PDF - 996 KB 12/2019 02/03/2021 Français

-

-

-

Service Manuals

-

Title Format Version Last change Language Service Manual Vacuum-Belt Applicator 5326C

PDF - 1.88 MB 08/2022 22/09/2022 English Service Manual Vacuum-Belt Applicator 5426C

PDF - 2.08 MB 09/2022 22/09/2022 English -

Other languages

-

Title Format Version Last change Language Serviceanleitung Saugband-Applikator 5326C

PDF - 1.87 MB 08/2022 22/09/2022 Deutsch Serviceanleitung Saugband-Applikator 5426C

PDF - 2.45 MB 09/2022 22/09/2022 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List Vacuum-Belt Applicator 5324C / 5326C

PDF - 756 KB 09/2022 22/09/2022 English Spare Parts List Vacuum-Belt Applicator 5426C

PDF - 1.19 MB 09/2022 22/09/2022 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste Saugband-Applikator 5324C / 5326C

PDF - 758 KB 09/2022 22/09/2022 Deutsch Ersatzteilliste Saugband-Applikator 5426C

PDF - 1.19 MB 09/2022 22/09/2022 Deutsch

-

-

-

Safety data sheets

-

Title Format Version Last change Language Safety Data Sheet Special Cleaner for Glass and Plastic GR1N

PDF - 65 KB 08/2017 23/10/2024 English Safety Data Sheet Special Rubber Cleaner WR1

PDF - 76 KB 12/2017 23/10/2024 English -

Other languages

-

Title Format Version Last change Language Sicherheitsdatenblatt Spezial Glasreiniger und Kunststoffreiniger GR1N

PDF - 156 KB 06/2017 25/08/2022 Deutsch Sicherheitsdatenblatt Spezial-Gummiwalzen-Reiniger WR1

PDF - 173 KB 06/2017 25/08/2022 Deutsch

-

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Well-trained cab service engineers worldwide support in the maintenance and repair of the devices.