Marking lasers

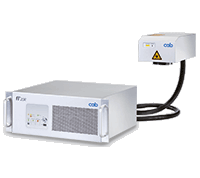

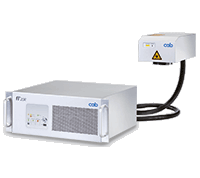

FL+

Precise, fast, economic - cab fibre lasers

The performance and quality of a marking mainly depends from the output power and the laser beam focus. cab FL+ marking lasers are diode-pumped and air-cooled. They have high beam quality and pulse peak power. Laser source output powers are from 20 to 50 Watt.

The performance and quality of a marking mainly depends from the output power and the laser beam focus. cab FL+ marking lasers are diode-pumped and air-cooled. They have high beam quality and pulse peak power. Laser source output powers are from 20 to 50 Watt.

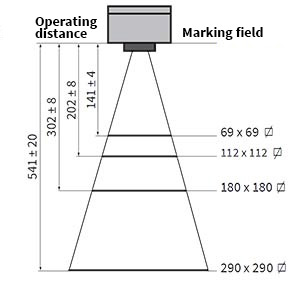

Different plano-spherical lenses allow marking in fields from 69 x 69 to 290 x 290 mm. Marking is possible on plastics and metals as well as on coated surfaces.

FL+ marking lasers consist of two units: The control unit has a laser source already integrated. The scan head is connected to the laser source via a fiber. It may be assembled in all possible position.

cab marking lasers stand for

- innovative technologies,

- focus on smallest spaces,

- high marking speeds,

- flexibility,

- resistancy

The control unit with the laser source are incorporated in a 19’’ rack.

Technical data of plano-spherical lenses F-Theta

Lenses are available for marking fields of various dimensions. The smaller the marking field, the higher the resolution.

| Plano-spherical lens | 100.1 | 160.1 | 254.1 | 420.1 |

|---|---|---|---|---|

| Operating distance FL+ mm | 141±4 | 202 ± 8 | 302 ± 8 | 541 ± 20 |

| Marking field mm | 69 x 69 | 112 x 112 | 180 x 180 | 290 x 290 |

| Spot diameter μm | ~25 | ~35 | ~50 | ~85 |

| ≙ Resolution dpi | 1.000 | 725 | 500 | 300 |

Video: cab Laser-Integration 1 - Robotik

Laser Integration in Production Line with 5 - Axis Robot.

XENO 1 is a compact desktop system, offering little footprint and a large work area.

| Marking laser | FL+20 | FL+30 | FL+50 |

|---|---|---|---|

| Laser source | Ytterbium fiber laser, pulsed, air-cooled | ||

| cw output power max. W | 20 | 30 | 50 |

| Pulse energy mJ | 1 | 1 | 1 |

| Wave length nm | 1064 | ||

| Beam quality M2 | < 1.8 | ||

| Pulse width ns | 80-120 | ||

| Pulse frequency kHz | 2-200 | 2-200 | 2-200 |

| Fiber coupling m | 2.5 | 2.5 | 2.5 |

| Scan head | |||

| Mounting | Horizontal/vertical | ||

| Marking speed mm/s | ~5000 | ||

| Pilot laser | |||

| Wave length nm | 650 | ||

| cw output power max. mW | < 1 | ||

| Electronics | |||

| Processor 32 bit clock rate MHz | 600 | ||

| Main memory (RAM) MB | 256 | ||

| Data memory (Flash) MB | 512 | ||

| Extensions (Flash) | USB memory stick | ||

| Dimensions and weights | Rack 4 RU 19“ | ||

| Control unit W x H x D mm | 420 x 178 x 420 | ||

| Control unit weight kg | 16 | ||

| Scan head W x H x D mm | 170 x 110 x 330 | ||

| Scan head weight kg | 7 | ||

| Control panel | |||

| Key switch | Laser source ON/OFF | ||

| Push button pilot laser | ON/OFF | ||

| Push button shutter open | OPEN/CLOSE | ||

| Indicator emission | Laser source active | ||

| Indicator laser error | Laser source error | ||

| Indicator ready | Laser source ready | ||

| Indicator power | Power supply ON | ||

| Indicator pilot laser | ON | ||

| Indicator shutter open | Safety circuit open | ||

| Connection service | USB mini | ||

| Operating data | FL+20 | FL+30 | FL+50 |

| Operating voltage/frequency | 100-240 VAC ~ 50/60 Hz | ||

| Power | ON/OFF | ||

| Power consumption standby W | 65 | ||

| Power consumption max. W | 175 | 200 | 250 |

| Approvals | CE, FCC class A, ICE S3 | ||

| Laser safety class EN60825-1 | |||

| Laser safety class laser source | Class 4 | ||

| Laser safety class pilot laser | Class 2 | ||

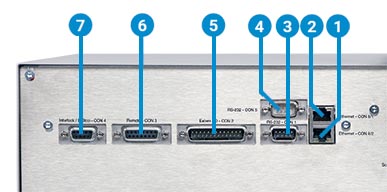

Interfaces

for process flow control

1 Ethernet 10/100 Mbit/s to connect a PC. As delivered, the device has been configured with an IP address or in DHCP mode.

2 Ethernet 10/100 Mbit/s to connect periphery. Bidirectional data transfer to end devices is enabled.

3 + 4 2 x RS232 C to connect periphery. Bidirectional data transfer to end devices is enabled.

5 Digitale I/O for control and monitoring. 8 freely programmable inputs and outputs are provided. Protective circuit according to IEC 61131-2

6 Remote to switch on the laser as well as for monitoring.

7 Interlock/E-Stop to integrate to external safety circuits and to connect an external E-stop.

Video: cab laser integration 1 - Robotics

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- cab Laser-Integration 1 - Robotics (WMV, 2,6 MB)

- cab Laser-Integration 1 - Robotics (MPEG-4, 2,7 MB)

Video: cab laser integration 2 - Robotics

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- cab Laser-Integration 2 - Robotics (WMV, 7,9 MB)

- cab Laser-Integration 2 - Robotics (MPEG-4, 3,9 MB)

Video: cab laser integration 3 - Vibration Conveyor

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- cab Laser-Integration 3 - Vibration Conveyor (WMV, 5,9 MB)

- cab Laser-Integration 3 - Vibration Conveyor (MPEG-4, 3,1 MB)

cab Laser Robo Marking Cell - LRMC

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- cab Laser Robo Marking Cell - LRMC (WMV, 62,4 MB)

- cab Laser Robo Marking Cell - LRMC (MPEG-4, 19,2 MB)

Download players:

- For WMV: Windows Media Player

- For MPEG-4: VLC Player

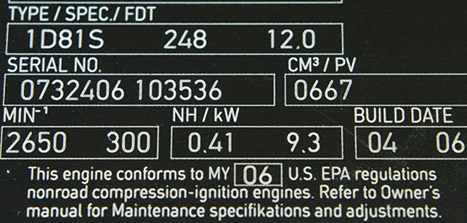

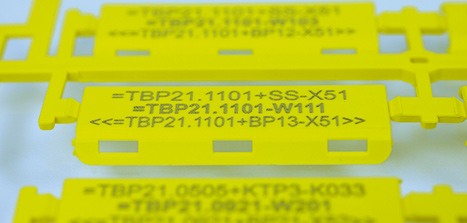

Sample applications

cab marking laser systems mainly work with metals and plastics. Depending from the requirement and material, different methods are known:

Engraving

Evaporation with high energy density removes the material. An indentation with a sharp outline occurs.

Annealing

is mainly applied with highly alloyed stainless steel as well as with titanium.

Ablating

The laser ablates the top layer to uncover the underneath material. Examples include anodized layers or paint coatings.

Coloring

is applied with plastics. The way the color changes depends from the chemical composition of the material as well as from ingredients and fillers.

Foaming

The laser melts into the surface of the material.

The model FL+10 (10 Watt variant) is not available any more. Please inform yourself about repair, service and spare parts availability for the model on our page: Discontinued Products.

Documentation

-

Catalogs

-

Title Format Version Last change Language Marking laser FL+

PDF - 2.74 MB 02/2023 11/04/2023 English Overview Product Marking

PDF - 6.70 MB 01/2026 20/01/2026 English

-

-

Assembly Instructions

-

Title Format Version Last change Language Assembly Instructions FL+ from serial number 0000400

(incl. dimensional drawings)PDF - 2.58 MB 06/2017 23/01/2019 English Assembly Instructions FL+ up to serial number 0000399

(incl. dimensional drawings)PDF - 2.62 MB 04/2015 23/01/2019 English Integration FL+ into FL Peripherals

PDF - 415 KB 08/2018 23/01/2019 English

-

-

Programming

-

Title Format Version Last change Language PLC programmer's guide: cab FL+ remote API interface

PDF - 2.08 MB 11/2021 02/01/2024 English cab FL+ / XENO 4 remote API program example Siemens

ZIP - 4.56 MB 03/2016 12/03/2021 –

-

-

Case study

-

Title Format Version Last change Language ZF TRW uses fiber lasers to encode gas generators

Inspiring ideas for passenger protectionPDF - 2.05 MB December 2016 12/01/2017 English

-

3D CAD models

The files are provided in STEP format, which requires CAD software. Follow this link to download a free STP Viewer: VariCAD Viewer (External website).

Select the desired model and click on the link. A short registration follows. cab will handle your personal information as described in our Privacy statement. This information will not be accessible to any third party for marketing purposes. You will receive an email with an activation link and you can download the models.

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Software & Drivers

-

Software

-

Title Format Version Last change Language cabLaseEditor (TCP/IP)

ZIP - 153.22 MB 5.3.4.7 i01 11/08/2025 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader