Label dispensers

HS and VS

Dispensing labels - automatical or on request

Easy operation and precise label dispensing for a great price

Every label size can be dispensed easily using the HS and VS dispenser. The labels can be stamped or cut without any space in between.

You can use any outside shape whether cornered or round. Transparent material can also be dispensed.

Two dispensing directions

Two versions are available so as to ensure that the labels can be removed properly for every use.

vergrößern

vergrößern

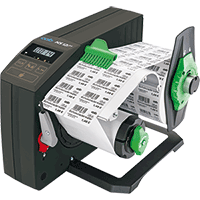

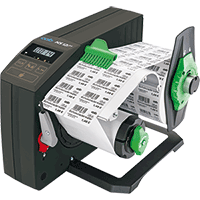

HS Horizontal dispensing direction

for label rolls with bottom leading print image

for label rolls with bottom leading print image

Peel off the label upwards from its bottom edge and stick it to the product.

vergrößern

vergrößern

VS Vertical dispensing direction

for label rolls with top leading

for label rolls with top leading

print image

Peel off the label forward from its upper edge and stick it to the product from the shortest distance possible. Particularly suitable for larger labels as the adhesive side is already directed to the product.

Two operation panels

Basic version

Label feed

- automatically after removal of the label

With operation panel

Label counter from 0 - 9,999

Label feed

- slow / fast

- after pressing the push button or

- automatically after removal of the label or

- by an external signal on the rear side of device

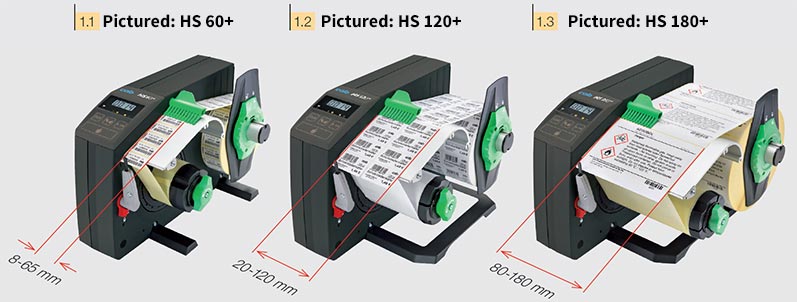

Three widths of material for HS and VS

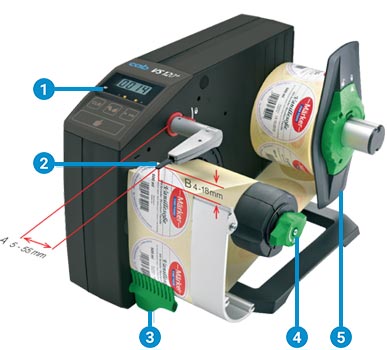

1 Operation panel

Use the operation panel to select various operating modes. This allows setting the feed supply rate to either "slow" or "fast". Labels are fed automatically after removal, by pressing a control key or upon an external signal. A counter indicates how many labels have already been removed.

2 Label sensor

For round labels, the sensor will be set to the label's A apex. You can adjust the pre-dispense height B to between 4 and 18 mm.

3 Label brake

This puts the base material under tension so as to ensure that the labels will be dispensed safely. It can be swivelled away easily when the material is changed.

4 Liner rewinder

Simply insert and clamp the backing tape immediately behind the peel-off edge. It is wound up completely by the strong motor.

5 Roll holder

The label rolls are guided by the stable roll retainer.

Overview technical data HS and VS (PDF)

Standard

Standard

| Common technical data | HS | VS | with operation panel "+" | |

|---|---|---|---|---|

| Dispensing direction | horizontal | vertical | ||

| Label orientation - print image | bottom leading | top leading | ||

| Labels | on rolls, standard or die cut, fan-folded optional | |||

| Materials | paper, textiles, plastics also transparent | |||

| Feed supply rate up to mm/sec | 200 | 100 / 200 | ||

| Label roll: outside diameter up to mm | 200 | |||

| Label roll: core diameter mm | 38 - 76 | |||

| Label roll: weight max. kg | 4 | |||

| Label roll: winding direction | outside or inside | |||

| Rewinder | ||||

| Liner outside diameter up to mm | 155 | |||

| Label sensor | ||||

| Scanning | leading edge of label | |||

| Distance to leading edge mm A mm | 5 - 55 | |||

| Pre-dispense: B mm | 4 - 18 | |||

| Operation panel | ||||

| Device indicator "ON" | green LED | LED and label counter "ON" | ||

| Device indicator Error | red LED | Label counter, flashing | ||

| Selector switch: label feed automatic or on demand | - |  |

||

| Control button with label feed on demand | - |  |

||

| Selector switch feed supply rate | - | slow / fast | ||

| LCD display label counter | - | 0 - 9999 | ||

| Control button reset label counter | - |  |

||

| Display dispensing via external signal | - |  |

||

| Connections | ||||

| Peripheral connection for peel-off on demand via external signal | - |  |

||

| Inlet connector for non-heating apparatus | Power supply | |||

| Power switch | On / Off | |||

| Operating data | HS and VS | mobile | |

| Power supply | 100 - 240 V ~ 50/60 Hz | 16,5 - 25 VDC | |

| Power consumption | standby < 5 W / typical 30 W / max. 100 W | ||

| Temperature / humidity: operation | +5 - 40°C / 10 - 85% non-condensing | ||

| Temperature / humidity: storage | +0 - 60°C / 20 - 80% non-condensing | ||

| Temperature / humidity: transport | - 25 - 60°C / 20 - 80% non-condensing | ||

| Noise level | < 60 dB | ||

| Approvals | CE, FCC Class A, ICES-3, cULus | ||

| Device specific dimensions | HS60 and VS60 | HS120 and VS120 | HS180+ and VS180+ |

| Width of labels including liner mm | 8 - 65 | 20 - 120 | 80 - 180 |

| Height of labels one-wide mm | 5 - 300 | 8 - 600 | 20 - 600 |

| Height of labels multi-wide mm | 5 - 110 | 8 - 110 | 20 - 110 |

| Device dimensions | |||

| Height x depth without material mm | 250 x 360 | 250 x 360 | 250 x 360 |

| Width mm | 180 | 230 | 300 |

| Weight kg | 3,3 | 3,6 | 4,0 |

Video: Label dispenser HS and VS

Powered by YouTube. See all cab videos: cab Channel auf YouTube.

Other formats

- Label dispenser HS and VS (WMV, 91 MB)

- Label dispenser HS and VS (MPEG-4, 89 MB)

Download players:

- For WMV: Windows Media Player

- For MPEG-4: VLC Player

Documentation

-

Catalogs

-

Title Format Version Last change Language Label dispenser HS and VS

PDF - 1.56 MB 08/2023 16/08/2023 English Overview Product Marking

PDF - 6.26 MB 04/2024 23/04/2024 English

-

-

Operation Manuals

-

Title Format Version Last change Language Operator's Manual HS/VS

PDF - 1.69 MB 10/2017 30/11/2020 English Operator's Manual HS/VS mobile (completion)

PDF - 45 KB 06/2014 30/11/2020 English -

Other languages

-

Title Format Version Last change Language Инструкция за експлоатация Уред за отлепване на етикети HS/VS bg

PDF - 1.13 MB 10/2017 26/11/2020 Български Návod k obsluze Dávkovač etiket HS/VS cz

PDF - 1.11 MB 10/2017 26/11/2020 Čeština Brugsanvisning Etiketdispenser HS/VS da

PDF - 1.07 MB 10/2017 25/11/2020 Dansk Bedieningshandleiding Etikettenverdeler HS/VS nl

PDF - 1.07 MB 10/2017 25/11/2020 Nederlands Käyttöohje Etiketinsyöttölaite HS/VS fi

PDF - 1.05 MB 10/2017 26/11/2020 Suomi Bedienungsanleitung Etikettenspender HS/VS de

PDF - 1.70 MB 10/2017 26/11/2020 Deutsch Οδηγίες χρήσης Ετικετέζα HS/VS el

PDF - 1.13 MB 10/2017 26/11/2020 ελληνικά Kezelési utasítás Címkeadagoló HS/VS hu

PDF - 1.11 MB 10/2017 25/11/2020 Magyar Bruksanvisning Etikettdispenser HS/VS no

PDF - 1.09 MB 10/2017 26/11/2020 Norsk Instrukcja obsługi Dyspenser etykiet HS/VS pl

PDF - 1.11 MB 10/2017 25/11/2020 Polski Manual de instruções Distribuidor de etiquetas HS/VS pt

PDF - 1.10 MB 10/2017 26/11/2020 Português Ghid de utilizare Ghidul utilizatorului Aplicator de etichete HS/VS ro

PDF - 1.11 MB 10/2017 25/11/2020 Română Руководство по эксплуатации Диспенсер этикеток HS/VS ru

PDF - 1.13 MB 10/2017 26/11/2020 Pусский Navodila za uporabo Podajalec etiket HS/VS sl

PDF - 1.10 MB 10/2017 30/11/2020 Slovenščina Manual de instrucciones Dispensador de etiquetas HS/VS es

PDF - 1.09 MB 10/2017 25/11/2020 Español Bruksanvisning Etikettdispenser HS/VS sv

PDF - 1.07 MB 10/2017 25/11/2020 Svensk Kullanım Kılavuzu Etiket dispenseri HS/VS tr

PDF - 1.11 MB 10/2017 26/11/2020 Türkçe Istruzioni per l'uso HS/VS

PDF - 1.07 MB 10/2017 30/11/2020 Italiano Manual de instrucciones HS/VS

PDF - 1.09 MB 10/2017 30/11/2020 Español Manuel d'utilisation HS/VS

PDF - 1.70 MB 10/2017 30/11/2020 Français

-

-

-

Service Manuals

-

Title Format Version Last change Language Adjusting Instruction Dispens Plate HS120

Adjusting the material run with changing the dispense platePDF - 759 KB 07/2012 20/07/2012 English/Deutsch Adjusting Instruction Dispens Plate VS120

Adjusting the material run with changing the dispense platePDF - 843 KB 07/2012 20/07/2012 English/Deutsch

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List HS/VS

PDF - 711 KB 11/2023 08/11/2023 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste HS/VS

PDF - 716 KB 11/2023 08/11/2023 Deutsch

-

-

-

Manuals Accessories

-

Title Format Version Last change Language Operator's Manual Battery Pack HS/VS

PDF - 397 KB 03/2016 14/03/2016 English Mounting Instructions Fanfold Media Guide

PDF - 194 KB 08/2012 18/03/2015 English

-

-

EU Declarations of Conformity - Accessories

-

Title Format Version Last change Language EU Declaration of Conformity Battery Pack HS/VS

PDF - 132 KB 10/2017 06/10/2017 English

-

-

Spare Parts Accessories

-

Title Format Version Last change Language Spare Parts List Battery Pack HS/VS

PDF - 280 KB 03/2015 18/03/2015 English

-

-

Case study

-

Title Format Version Last change Language Mittelstand 4.0 roadshow: Label printers and dispensers qualify for future technologies

PDF - 1.57 MB 02/2022 09/02/2022 English -

Other languages

-

Title Format Version Last change Language Mittelstand 4.0-Roadshow: Etikettendrucker und -spender befähigen zu Technologien von morgen

PDF - 1.98 MB 02/2022 09/02/2022 Deutsch

-

-

-

Safety data sheets

-

Title Format Version Last change Language Safety Data Sheet Special Cleaner for Glass and Plastic GR1N

PDF - 65 KB 08/2017 02/02/2023 English Safety Data Sheet Special Rubber Cleaner WR1

PDF - 76 KB 12/2017 02/02/2023 English -

Other languages

-

Title Format Version Last change Language Sicherheitsdatenblatt Spezial Glasreiniger und Kunststoffreiniger GR1N

PDF - 156 KB 06/2017 25/08/2022 Deutsch Sicherheitsdatenblatt Spezial-Gummiwalzen-Reiniger WR1

PDF - 173 KB 06/2017 25/08/2022 Deutsch

-

-

3D CAD models

The files are provided in STEP format, which requires CAD software. Follow this link to download a free STP Viewer: VariCAD Viewer (External website).

Select the desired model and click on the link. A short registration follows. cab will handle your personal information as described in our Privacy statement. This information will not be accessible to any third party for marketing purposes. You will receive an email with an activation link and you can download the models.

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader