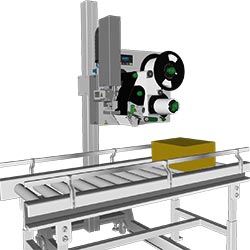

Linerless print and apply systems

HERMES QL/QI

HERMES QL for Linerless, HERMES QI for InNo-Liner

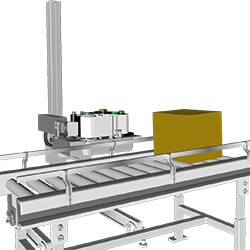

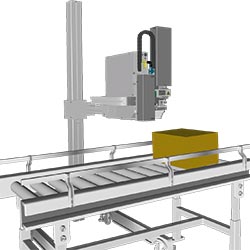

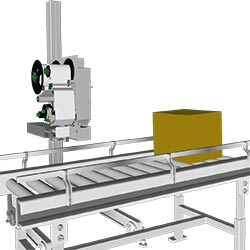

Various linerless materials can be processed with a base unit, print rollers and applicators be selected according to an application. Disposal of liner materials and associated costs are eliminated.

A maximum of 40 percent more labels fit onto a roll, which in turn is easier in transport. System downtimes are reduced due to fewer roll changeovers. By activating a saving feature, material is cut automatically subsequent to a final print line and an offset.

Full compatibility: Features, dimensions and installation correspond to the tried and tested HERMES Q systems.

A large extent of applicators and assembly assistances can be used in original, HERMES Q standard and QL linerless printers be switched back and forth easily.

Cycle rates correspond to HERMES Q applicators, added by about 50 milliseconds delay time for cutting the linerless labels.

Materials in comparison

Adhesive label on liner

- Any kind of application by labels made of different materials

- Thermal transfer, direct thermal

- Label liner

- Costs associated with liner waste disposal

- Silicone coated liner

- Higher CO2 emissions due to higher transport volumes and weights

- Stock space required to a greater extent

- 450 m of material with a roll diameter of 300 mm

- Downtimes and costs in greater numbers by roll changeovers

- Labels of the same length

Linerless

- Any kind of application onto packaging in industry and logistics

- Direct thermal

- No liner

- Eco-friendly, no costs associated with liner waste disposal

- Silicone coated label surface

- Less CO2 emissions due to lower transport volumes and weights

- Less stock space required

- 700 m of material with a roll diameter of 300 mm

- Less downtimes and costs by fewer roll changeovers

- Labels of various lengths

InNo-Liner

- Application onto absorbent cardboard and paper surfaces, in particular shipping labels in logistics

- Direct thermal

- No liner

- Eco-friendly, no costs associated with liner waste disposal

- No silicone

- Less CO2 emissions due to lower transport volumes and weights

- Less stock space required

- 750 m of material with a roll diameter of 300 mm

- Less downtimes and costs by fewer roll changeovers

- Labels of various lengths

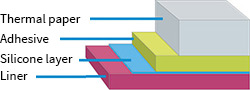

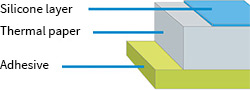

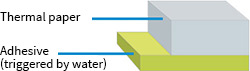

Composition

Adhesive label on liner

Linerless

InNo-Liner

HERMES print and apply systems in comparison

| HERMES Q for self-adhesive labels |

HERMES QL for Linerless |

HERMES QI for InNo-Liner |

| Materials | ||

| Self-adhesive labels on a liner | Continuous linerless materials | Continuous InNo-Liner materials |

| Adhesive | ||

| permanent | permanent | triggered by water in micro-vaporisation |

| Print methods | ||

| Thermal transfer, direct thermal | Direct thermal | Direct thermal |

| Print widths | ||

| as wide as 168 mm | as wide as 108.4 mm (168 mm on request) | as wide as 108.4 mm (168 mm on request) |

| Print speeds | ||

| as fast as 300 mm/s | as fast as 250 mm/s | as fast as 250 mm/s |

| Print rollers | ||

| Standard roller or silicone material | Roller with anti-stick coating | Standard roller Silicone material |

| Print heads | ||

| Print head 4 300 dpi Print head 4 600 dpi Print head 4.3 200 dpi Print head 4.3 300 dpi |

Print head 4.3 200 dpi Print head 4.3 300 dpi |

Print head 4.3 200 dpi Print head 4.3 300 dpi |

| Roll diameters if chassis dimensions are identical | ||

| 205 mm | max. 300 mm | max. 300 mm |

| Length of materials if chassis dimensions are identical | ||

| 180 m | 700 m | 750 m |

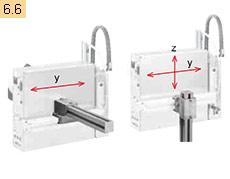

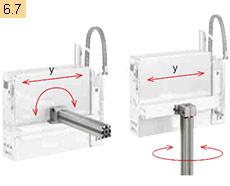

| Orientations of assembly when labeling onto packaging | ||

| vertical, horizontal | vertical, horizontal | vertical |

| Applicators | ||

| full range of HQ applicators | HQ 3014, HQ 4014, HQ 4024, HQ 4614, HQ 5314, HQ 5414, HQ 6114 | HQI 4034 |

| Applications | ||

| any kind of product or packaging | any kind of packaging | absorbent cardboard surfaces |

Common features

| Printer dimensions, firmware, user interface, interfaces, applicator connectivity, assembly assistance |

Video: Linerless print and apply systems HERMES QL

for printing linerless labels and applying them automatically

Conserving resources a result of linerless labeling. DHL adopts InNo-Liner solution from cab and HERMA.

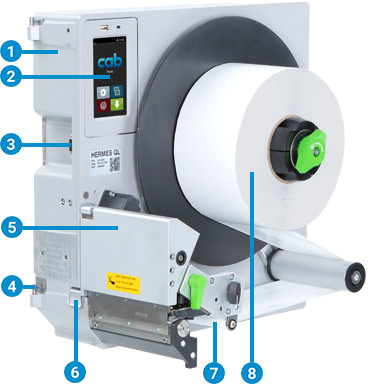

1 Metal chassis

It is the base for component assembly. Made of cast aluminum

2 Operation panel

Intuitive and easy configuration with the help of self-explanatory symbols on the user interface

3 Peripheral port

An applicator can be plugged easily and quickly.

4 Applicator

Pivotable for maintenance or material changeover

5 Cutter

for separating continuous materials

6 Unlocking lever

for pivoting and removing a cutter

7 Deflection roller

Axially adjustable for materials running straight

8 Label unwinder

A pendulum arm and an integral brake keep a label web under constant tension.

Cutter

It separates even printed labels of different heights.

Blade and cutter bar each have anti-stick coating.

The entire cutter can be quickly and easily removed and reinstalled without additional tools in cases of cleaning, changing a print roller or maintaining a print head.

Print head

It is designed for direct thermal printing.

Major data such as operational performance, maximum operation temperature and heating are kept in memory. The data can be read at the premise.

Linerless print roller

DRL4 print roller, designed for continuous linerless materials, anti-stick-coated

InNo-Liner print roller

DRS4 print roller, designed for continuous InNo-Liner material, silicone-coated

Interfaces

1 Port for plugging a SD memory card

2 2 USB hosts for plugging a service key, an USB stick, a keyboard, a barcode scanner, an USB WLAN stick, a warning light, an external control panel

3 USB 2.0 Hi-Speed device for plugging a PC

4 Ethernet 10/100 Mbit/s

5 RS232C 1,200 to 230,400 baud/8 bit

6 Digital I/O interface

SUB-D socket connector, 25 pins, compliant to IEC/EN 61131-2, type 1+3

The inputs and outputs are galvanically isolated and protect from reverse polarity. The outputs are also short-circuit-proof.

PNP inputs

Start printing / applying

Print first label

Reprint

Delete print job

Label removed

Stop printing / applying

Label feed

Pause

Reset

PNP, NPN outputs

Unit ready

Print data available

Initial / upper end position

Paper feed ON

Label peel-off

Label apply / lower end position

Prior warning to label web ending

Label web ending

Collective error

Options

7 Port for additional interfaces

Conserving resources a result of linerless labeling. DHL adopts InNo-Liner solution from cab and HERMA.

standard

standard  option

option

| Label printerType | HERMES QL4.3, HERMES QI4.3 | |

|---|---|---|

| Print method | Direct thermal | |

| Print resolutiondpi | 200 | 300 |

| Print speedmm/s max. | 250 | 250 |

| Print width mm max. | 104 | 108.4 |

| Print length mm max. | 13,500 | 9,000 |

| Direction to which labels are dispensed | L = to the left, R = to the right | |

| Print distant to locating edgemm | 1 | |

| Material | ||

| Continuous linerless material wound onto a roll | Direct thermal paper | |

| Label Widthmm | 50 - 105 | |

| Label Heightmm | 30 - 456 | |

| Label Thickness μm max. | 110 | |

| Unwinder Roll outside diametermm max. | 300 | |

| Unwinder Roll core diametermm | 76 | |

| Unwinder Winding outside |  |

|

| Printer dimensions, weights | ||

| Width x Height x Depthmm | 260 x 400 x 400 | |

| Weight kg approx. | 13 | |

| Weight cover includedkg approx. | 15.5 | |

| Material control | ||

| both end positions on pendulum arm |  |

|

| Electronics | ||

| Processor, 32 bit clock rateMHz | 800 | |

| RAM MB | 256 | |

| IFFSMB | 50 | |

| Port for plugging a SD memory card (SDHC, SDXC) |  |

|

| Battery for indicating time and date, real-time clock |  |

|

| Data kept in memory (e.g. serial numbers) when power turns off |  |

|

| Interfaces | ||

| RS232-C 1,200 to 230,400 baud / 8 bit |  |

|

| USB 2.0 Hi-Speed device for plugging a PC |  |

|

| Ethernet 10/100 Mbit/s IPv4 and IPv6 |

LPD, RawIP printing, SOAP web service, OPC UA, WebDAV, DHCP, HTTP/HTTPS, FTP/FTPS, TIME, NTP, Zeroconf, SNMP, SMTP, VNC | |

| 2 USB hosts on the control panel, 2 USB hosts on the back of a unit |

Service key, USB stick, USB WLAN stick, USB WLAN stick with a rod antenna, keyboard, barcode scanner, warning light, external control panel | |

| USB host, 24 VDC, for peripheral / applicator plugging |  |

|

| Digital I/O interface providing 10 inputs and 11 outputs |  |

|

| Operating data | ||

| Voltage | 100 – 240 VAC ~ 50/60 Hz, PFC | |

| Consumption of power | <10 W in standby / 100 W in typical operation / max. 200 W | |

| Temperature / humidity Operation | +5 - 40°C / 10 - 85 %, not condensing | |

| Temperature / humidity Stock | 0 - 60°C / 20 - 85 %, not condensing | |

| Temperature / humidity Transport | –25 - 60°C / 20 - 85 %, not condensing | |

| Approvals | CE, FCC Class A, ICES-3 | |

| in preparation | UKCA, cULus, CB | |

| Approvals upon request | CCC, BSMI, KC-Mark, Mexico Reg., RCM | |

| Operation panel | ||

| Color LCD touchscreen Diagonal " |

4.3 | |

| Color LCD touchscreen Resolution Width x Heightpx | 272 x 480 | |

For more technical data please read the product brochure (PDF)

Conserving resources a result of linerless labeling. DHL adopts InNo-Liner solution from cab and HERMA.

Conserving resources a result of linerless labeling. DHL adopts InNo-Liner solution from cab and HERMA.

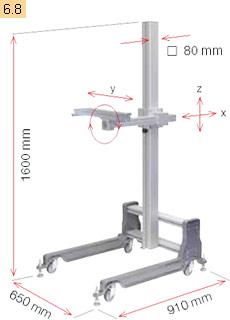

HERMES QL/QI options

Cover

A hinged cover with a large inspection window protects the material and the print head from contamination.

Installation:

vertical, rotated by± 90°, horizontal

2 port Ethernet switch 10/100 Mbit/s

for plugging another terminal device in a joint network. Signals are looped through.

HERMES QL/QI wear parts

DRS4 print roller

for continuous InNo-Liner material

DRL4 print roller

for continuous Linerless material

Conserving resources a result of linerless labeling. DHL adopts InNo-Liner solution from cab and HERMA.

Video: Linerless print and apply systems HERMES QL

for printing linerless labels and applying them automatically

cab video tutorials HERMES QL

Conserving resources a result of linerless labeling. DHL adopts InNo-Liner solution from cab and HERMA.

Continuous linerless materials

Linerless RL540

On packaging of all kinds in industry and logistics

InNo-Liner IDL

On absorbent cardboard and paper surfaces, such as shipping labels in logistics

All materials are free from bisphenols and suit for use in food business.

- CO2 neutral

- waste is avoided

| Material | Linerless RL540 | InNo-Liner IDL | |

|---|---|---|---|

| Type | Direct thermal paper, white | Direct thermal paper, white | |

| Thickness | approx. 80 μm | 84 μm | |

| Adhesive | self-adhesive | triggered by water | |

| Grip | permanent | permanent | |

| Food recommendation | not specified | BfR XXXVI | |

| Application temperature | from 5°C | 10°C - 30°C | |

| Service - Temperature - Humidity |

–10 - 100°C not specified |

–20°C - 50°C 20 % - 85 %, not condensing |

|

| Shelf life - Temperature - Humidity |

12 month 23°C ± 5°C 50 % ± 10 % |

24 month1) 20°C - 25°C 40 % - 50 %, not condensing |

|

| Application | indoor | indoor | |

| Material | Item no. | Material width mm | Material length m | Roll diameter mm | Core diameter mm | Winding |

|---|---|---|---|---|---|---|

| Linerless RL540, 58 mm x 700 m | 5780400 | 58 | 700 | 300 | 76 | outside |

| Linerless RL540, 80 mm x 700 m | 5780401 | 80 | 700 | 300 | 76 | outside |

| Linerless RL540, 105 mm x 700 m | 5780402 | 105 | 700 | 300 | 76 | outside |

| InNo-Liner IDL, 60 mm x 750 m | 5780300 | 60 | 750 | 300 | 76 | outside |

| InNo-Liner IDL, 80 mm x 750 m | 5780301 | 80 | 750 | 300 | 76 | outside |

| InNo-Liner IDL, 100 mm x 750 m | 5780302 | 100 | 750 | 300 | 76 | outside |

Conserving resources a result of linerless labeling. DHL adopts InNo-Liner solution from cab and HERMA.

Documentation

-

Catalogs

-

Title Format Version Last change Language HERMES QL / QI with HQ / HQI applicators

PDF - 3.55 MB 09/2025 17/09/2025 English Overview Product Marking

PDF - 6.70 MB 01/2026 20/01/2026 English

-

-

Assembly Instructions

-

Title Format Version Last change Language Assembly instructions HERMES QL

PDF - 6.44 MB 05/2025 03/07/2025 English -

Other languages

-

Title Format Version Last change Language Montageanleitung HERMES QL

PDF - 6.46 MB 05/2025 03/07/2025 Deutsch

-

-

-

Programming

-

Title Format Version Last change Language Brief introduction to cab printer programming

PDF - 7.47 MB 04/2022 15/01/2025 English cab Download Converter (download.exe)

Converts image, font and database files into the JScript download data format.

Install MS Visual C++ 2010 Redistributable if not available on your system.ZIP - 9 KB 2.3 25/10/2024 – cab Remote Control

Remote control of cab systems for label printing / Fernsteuerung von cab Drucksystemen - HERMES Q, SQUIX, PX QZIP - 3.50 MB 2021/07 15/01/2025 English/Deutsch cabPROTECT - Data security in label printing

PDF - 472 KB 06/2024 20/06/2024 English Connecting cab printing systems to SAP®

CompendiumPDF - 4.45 MB 01/2025 11/02/2025 English Networked labeling with OPC UA

cab and the Smart FactoryPDF - 1.12 MB 03/2019 15/01/2025 English PLC Programmer's Guide HERMES Q, SQUIX, XD Q, PX Q

with label layouts and programming examplesZIP - 16.17 MB 06/2020 22/12/2025 English Programming Manual abc Basic Compiler

for cab printersPDF - 755 KB 11/2024 29/11/2024 English Programming Manual JScript

for SQUIX, MACH 4S, EOS2, EOS5, XC Q, XD Q, HERMES Q, PX Q, AXON1, AXON 2, A+, HERMES+, A-Series, EOS1/4, MACH4, XD, XCPDF - 4.30 MB 05/2025 23/05/2025 English ZPL Emulation with cab printers

PDF - 2.28 MB 05/2025 23/05/2025 English -

Other languages

-

Title Format Version Last change Language Anbindung von cab Drucksystemen an SAP®

KompendiumPDF - 4.55 MB 01/2025 11/02/2025 Deutsch cabPROTECT - Datensicherheit beim Etikettendruck

PDF - 475 KB 06/2024 20/06/2024 Deutsch Kurze Einführung in die cab Druckerprogrammierung

PDF - 7.50 MB 04/2022 12/04/2022 Deutsch Marquage en réseau avec OPC UA

cab et l'usine intelligentePDF - 745 KB 01/2022 23/10/2024 Français SPS Programmieranleitung HERMES Q, SQUIX, XD Q, PX Q

mit Etikettenlayouts und BeispielprogrammenZIP - 16.22 MB 06/2020 18/04/2024 Deutsch Vernetzt kennzeichnen mit OPC UA

cab und die intelligente FabrikPDF - 1.13 MB 03/2019 28/01/2021 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List HERMES QL left

PDF - 867 KB 09/2025 16/09/2025 English Spare Parts List HERMES QL right

PDF - 877 KB 09/2025 16/09/2025 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste HERMES QL links

PDF - 881 KB 09/2025 16/09/2025 Deutsch Ersatzteilliste HERMES QL rechts

PDF - 891 KB 09/2025 16/09/2025 Deutsch

-

-

-

Safety data sheets

-

Title Format Version Last change Language Safety Data Sheet Special Cleaner for Glass and Plastic GR1N

PDF - 65 KB 08/2017 23/10/2024 English Safety Data Sheet Special Rubber Cleaner WR1

PDF - 76 KB 12/2017 23/10/2024 English -

Other languages

-

Title Format Version Last change Language Sicherheitsdatenblatt Spezial Glasreiniger und Kunststoffreiniger GR1N

PDF - 156 KB 06/2017 25/08/2022 Deutsch Sicherheitsdatenblatt Spezial-Gummiwalzen-Reiniger WR1

PDF - 173 KB 06/2017 25/08/2022 Deutsch

-

-

3D CAD models

The files are provided in STEP format, which requires CAD software. Follow this link to download a free STP Viewer: VariCAD Viewer (External website).

Select the desired model and click on the link. A short registration follows. cab will handle your personal information as described in our Privacy statement. This information will not be accessible to any third party for marketing purposes. You will receive an email with an activation link and you can download the models.

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Label software cablabel S3: Opens the full potential of cab devices

Printer control and administration: Drivers, programming, Connecting to SAP, OPC UA, Stand-alone

Software & Drivers

-

Firmware

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Firmware X4

Firmware SQUIX | EOS2 | EOS5 | MACH 4S | XD Q | XC Q | HERMES Q | PX Q | AXON 1ZIP - 55.09 MB 5.47.8 17/02/2026 – Release Notes Firmware X4

TXT - 135 KB

TXT - 135 KB

5.00 - 5.47.8 17/02/2026 –

-

-

Firmware periphery

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Firmware applicators SQ, HQ

SQ1000, SQ3200, HQ3014/3016, HQ3214, HQ4014/4016, HQ4024, HQ4114/4116, HQ4214, HQ4414, HQ4514, HQ4614, HQ6114ZIP - 52 KB 2.2.0 06/10/2025 – Firmware I/O 24V25-2, I/O 24V25-3, I/O 5V15-2 and I/O 5V15-3

ZIP - 23 KB 3.2.0 08/04/2025 –

-

-

Drivers

-

Title Format Version Last change Language cab Linux Armv7 - 32 Bit Driver

CUPS Linux Armv7 32bit Driver RPi 2/3/4 (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab Linux Armv8(aarch64) - 64 Bit Driver

CUPS Linux Armv8 64 Bit Driver RPi 3/4 (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab Linux x86 - 32 Bit Driver

CUPS Linux Intel 32bit Driver (min. CUPS 1.2)GZ - 2.81 MB 1.46 23/10/2024 – cab Linux x86 - 64 Bit Driver

CUPS Linux Intel/AMD 64bit Driver (min. CUPS 1.2)GZ - 2.80 MB 1.46 23/10/2024 – cab MAC OS Driver

Apple® Mac OS 10.15 - 26ZIP - 2.97 MB 1.46 27/02/2026 – cab MAC OS X Driver

Apple® Mac OS X 10.6 - 10.14ZIP - 5.82 MB 1.46 23/10/2024 – cab Windows Driver ARCHIV

Vista, Windows 7, Windows 8, Windows 8.1, Windows 10, Windows Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019 - 32/64 Bit CERTIFIED, works on Windows 11 (Not certified!)ZIP - 9.37 MB 5.3.03 24/10/2025 – cab Windows Driver NEW

Windows 10, Windows 11, Windows Server 2016, Windows Server 2019, Windows Server 2022, Windows Server 2025 - 64Bit, requires Visual C++ 2022ZIP - 24.01 MB 1.4.1.0 03/03/2026 – cab Windows Driver NEW Release Notes

PDF - 120 KB 1.2.1.20 - 1.4.1.0 24/03/2025 –

-

-

Software

-

Title Format Version Last change Language cab Download Converter (download.exe)

Converts image, font and database files into the JScript download data format.

Install MS Visual C++ 2010 Redistributable if not available on your system.ZIP - 9 KB 2.3 25/10/2024 – cablabel S3 Demo (Free)

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 51.42 MB 1.4.0.10 11/07/2025 – cablabel S3 Lite (Free)

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 69.78 MB 1.4.0.10 11/07/2025 – cablabel S3 Print

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 75.95 MB 1.4.0.10 11/07/2025 – cablabel S3 Pro

Windows Vista, 7, 8, 10, 11, Server 2008, 2008 R2, 2012, 2012 R2, 2016, 2019, 2022ZIP - 86.77 MB 1.4.0.10 11/07/2025 – Database Connector

Windows 32 & 64 bitZIP - 27.77 MB 4.4.0.0 21/01/2026 – LogService

for Database ConnectorZIP - 4.15 MB 1.7.1.0 25/10/2024 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader