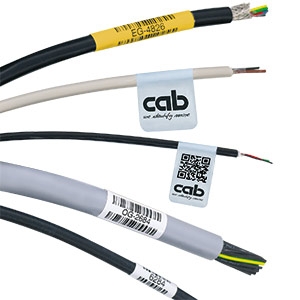

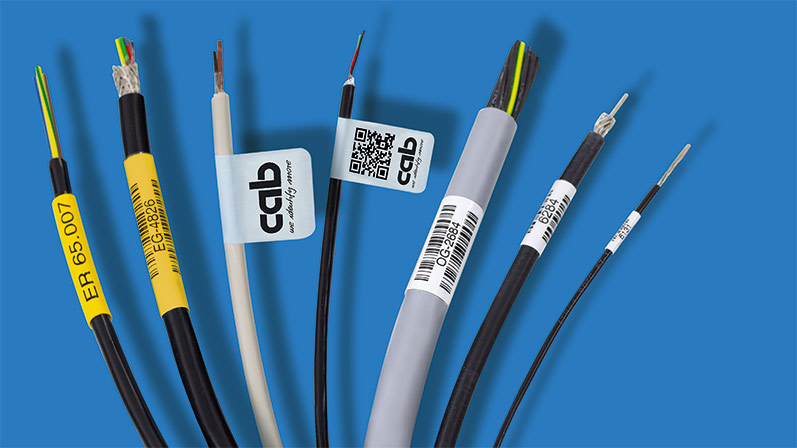

Labeling cables

Shrink tubes, label flags, wrap-around labels

EOS 2, EOS 5 label printers

for printing on one side of continuous pressed shrink tubes

EOS2 is the compact one, requiring little footprint on workstations. Label rolls with diameters up to 203 mm can be inserted to EOS5.

Continuous shrink tubes can be perforated, to simplify separation by hand at a later stage. Cutting a material is as well possible. The cutter can be pivoted to exchange the material.

| Label printer | EOS2 | EOS5 |

|---|---|---|

| Material guidance | centered | |

| Print method | Thermal transfer | |

| Print resolutiondpi | 300 | 300 |

| Print speed mm/s max. | 150 | 150 |

| Print widthmm max. | 105.7 | 105.7 |

| Finishing Roll diameter mm max. | 152 | 203 |

| Finishing Core diametermm | 38.1 - 76 | |

| Perforation cutter | |

|---|---|

| Perforation Distance between / width of off-cuts mm | 2.5 / 0.8 |

| Material Widthmm | 45 |

| Material Thicknessmm max. | 1.1 |

| Cutting length mm at least | 10 |

| Material passage mm max. | 2.5 |

| Pos. | Part no. | Designation | |

|---|---|---|---|

| 1.1 |  |

5978202 5965910 |

EOS 2/300 label printer Perforation cutter for EOS 2 |

| 1.2 |  |

5978212 5969891 |

EOS 5/300 label printer Perforation cutter for EOS 5 |

SQUIX 4M label printers

for printing on one side of shrink tubes continuous pressed or ready for use

The printers stand up to any demand, whether operated stand-alone, with a PC or in a network.

Continuous shrink tubes can be perforated, to simplify separation by hand at a later stage. Cutting a material is as well possible.

| Label printer | SQUIX 4M | |

|---|---|---|

| Material guidance | centered | |

| Print method | Thermal transfer | |

| Print resolutiondpi | 300 | 600 |

| Print speed mm/s max. | 300 | 150 |

| Print widthmm max. | 105.7 | 105.7 |

| Finishing Roll diametermm max. | 205 | |

| Finishing Core diametermm | 38.1 - 76 | |

| Perforation cutter | PSQ 403 |

|---|---|

| Perforation Distance between / width of off-cutsmm | 2.5 / 0.4 |

| Perforation Quantity of off-cuts | 6 |

| Material Widthmm max. | 114 |

| Material Thickness mm max. | 1.5 |

| Cutting length mm at least | 10 |

| Material passagemm max. | 2.0 |

| Pos. | Part no. | Designation | |

|---|---|---|---|

| 1.3 |  |

5977010.659 5977011.659 |

SQUIX 4/300M label printer incl. PSQ 403 perforation cutter SQUIX 4/600M label printer incl. PSQ 403 perforation cutter |

XD Q label printers

for printing on both sides of continuously pressed shrink tubes or shrink tubes ready for use

They print on both sides of pressed shrink tubes, continuous or ready for use.

Heating can be assigned separately to each print head. If required, labels can be printed on one side only.

Continuous shrink tubes can be perforated, to simplify separation by hand at a later stage. Cutting a material is as well possible.

| Label printer | XD Q4/ 300 | XD Q4.2/ 600 |

|---|---|---|

| Material guidance | centered | |

| Print method | Thermal transfer | |

| Print resolutiondpi | 300 | 600 |

| Print speedmm/s max. | 150 | 100 |

| Print widthmm max. | 105.7 | 54.1 |

| Finishing Roll diametermm max. | 300 | |

| Finishing Core diametermm | 38.1 - 76 | |

| Perforation cutter | PSQ 403 |

|---|---|

| Perforation Distance between / width of off-cuts mm | 2.5 / 0.4 |

| Perforation Quantity of off-cuts | 6 |

| Material Widthmm max. | 114 |

| Material Thicknessmm max. | 1.1 |

| Cutting lengthmm at least | 10 |

| Material passagemm max. | 2.0 |

| Pos. | Part no. | Designation | |

|---|---|---|---|

| 1.4 |  |

6011501 6011506 |

XD Q4/300 label printer incl. PSQ 403 perforation cutter XD Q4.2/600 label printer incl. PSQ 403 perforation cutter |

HERMES Q4L printer system with a 4712 flag applicator

Labels are applied precisely on round materials such as cables, hoses or pipes. First, both endings of a label are stuck together. Then the label is tamped onto the round material.

The pad locates next to the peel-off plate. Printed labels are picked up and transferred to the spot of application by a stroke cylinder.

A further cylinder guides the label all around the round material using cam control.

The length of the stroke cylinder defines the maximum distance of a product to the peel-off plate.

Label printers providing an

Label printers providing an

integral UHF RFID module will be

| Flag applicator | 4712L-300 | |

|---|---|---|

| Product Diametermm | 3 - 16 | |

| Label Widthmm | 501) - 100 | |

| Label Height mm | 10 - 50 | |

| Label Material | PET | |

| State of a product at the moment a label is applied | at rest | |

| Label applicationsfrom the top |  |

|

| Label applicationsfrom below |  |

|

| rotated vertically: 0 - 180° clockwise (request in case of other rotations) | ||

| Label applicationsfrom the side |  |

|

| Items of uniform height | uniform | |

| Product distance to the bottom of a unit using a cylinder stroke of 300 | mm at least | 70 |

| mm max. | 260 | |

| Depth of pliers immersing mm | 55 | |

| Offset P mm max. | 1.02) | |

| Compressed airbar | 4.5 | |

| Cycle rate, printing and applying only3) labels/min approx. | 15 | |

- Processing labels 50 to 58 mm wide requires a spacer.

- depending on the quality of a label material

- calculated using a print speed of 100 mm/s

| HERMES label printer | Q4L | |

|---|---|---|

| Guidance of a material | aligned to the left | |

| Print method | Thermal transfer | |

| Print resolution dpi | 300 | 600 |

| Print speedmm/s max. | 200 | 100 |

| Print width mm max. | 105.7 | 105.7 |

| Finishing Roll diametermm max. | 205 / 305 | |

| FinishingCore diametermm | 76 | |

| Assembly frame and collet chucks | upon request | |

| Pos. | Part no. | Designation | |

|---|---|---|---|

| 1.1 |  |

6010005 6010006 |

HERMES Q4L/300-2 label printer HERMES Q4L/600-2 label printer |

| 6010013 6010014 |

HERMES Q4L/300-3 label printer HERMES Q4L/600-3 label printer |

||

| 2.1 |  |

5971815 | 4712L-300 flag applicator |

For further options and accessories see HERMES Q

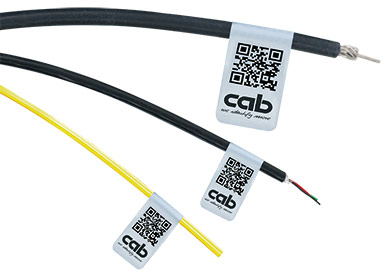

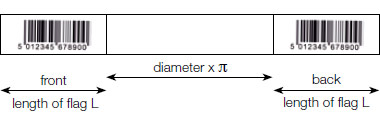

Label flags

Upper materials and adhesives have been developed in particular for reliable label flag processing.

A label entirely encloses a product. Once stuck, label flags remain permanently closed.

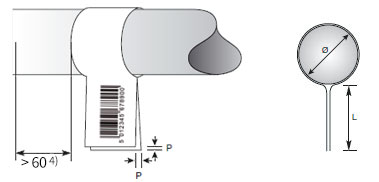

4. Flag on product requires >60 mm clearance on one side

UHF RFID tags

UHF RFID tags

in preparation

| Part no. | D1 min. mm | Flag L mm | D2 max. mm | Flag L mm | Label width B mm | Label height H mm |

No. of labels per roll at max. Ø 205 |

R71 resin ribbon width min. mm |

|---|---|---|---|---|---|---|---|---|

| 5775266 | 3 | 20 | 9.5 | 10.0 | 50 | 30 | 4,000 | 55 |

| 5770196 | 3 | 25 | 12.5 | 10.0 | 60 | 10 | 10,000 | 65 |

| 5706033 | 3 | 30 | 15.5 | 10.0 | 70 | 15 | 7,500 | 76 |

| 5771850 | 3 | 35 | 16.0 | 14.5 | 80 | 25 | 5,000 | 110 |

| 5773089 | 3 | 45 | 16.0 | 24.5 | 100 | 18 | 6,000 | 110 |

| 5771775 | 3 | 45 | 16.0 | 24.5 | 100 | 45 | 3,000 | 110 |

Thickness

Adhesive

Temperature

Operation

Resistances

Flammability

Roll finishing

40 μm

permanent

-80 °C to 150 °C

indoor, outdoor

water, dirt, petrol, oils, alcohol, detergents, UV light

self-extinguishing according to VTM-0

Outside ø max. 305 mm

Core ø 76 mm

Ribbons

| Part no. | PU 1 Roll |

PU 2 Rolls in cardboard box |

Width mm | Length m |

|---|---|---|---|---|

| 5557402.133 | 1 | 10 | 55 | 360 |

| 5557403.133 | 1 | 10 | 65 | 360 |

| 5557404.133 | 1 | 10 | 76 | 360 |

| 5557405.133 | 1 | 10 | 110 | 360 |

WICON wrap-around applicator

Cylindric items of diameters from 2 mm to 16 mm, such as single wires, strands, cables, hoses, tubes or round rods, can be labeled with the wrap-around applicator.

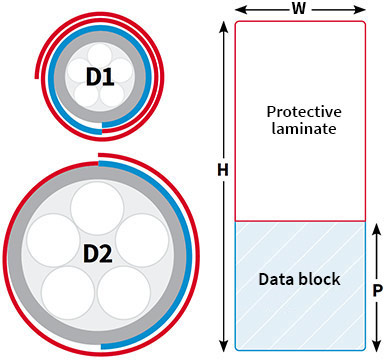

Transparent laminate covers data blocks and protects them persistently from dust and wear.

Items are inserted in horizontal orientation and centered by panels.

The following options are available for printing and labeling:

![]()

![]()

Pivoting the applicator allows label rolls or ribbons been replaced easily. Opening the service door enables access to the wrapper head in cases of errors, such as label jams.

- Single items are inserted by hand.

Items are positioned by centering panels.

Start is triggered automatically after insertion.

- Single items are inserted by a robot.

Items are identified by centering panels.

Start is triggered via a data or I/O interface.

- Continuous items are fed and positioned automatically.

Centering panels remain open by expansion.

Items are guided through the center.

Start is triggered via a data or I/O interface.

Item diameters and label lengths define the number of wrap-arounds. Cycles are 1.8 to six seconds.

While labels are wrapped around an item, the aperture for insertion and removal is covered by a finger guard. Operations require materials guided centered on a printer, as well as a slim print roller.

The data block of a label can be printed using cablabel S3, release 1.4.0.5 or later. Find sample labels on www.cab.de/en/cablabel

| Wrap-around applicator | WICON | |

|---|---|---|

| 1 Item diameter1) mm | 2.0 - 16.0 | |

| 2 Item length mm at least | 134 | |

| 3 Centering panel distant to left and rightmm | 124 | |

| 4 Item length label margin to stop mm | 25 - 120 | |

| mm5 Label margin distant to centering panel | 12.7 | |

| 5 Deflection related to a length of 124 mmmm max. | 1 | |

| 6 Label width mm | 12.7 - 50.8 | |

| 6 Label height mm | 19.1 - 70.0 | |

| Applicator Cycle of printing and applying Applicator Cycle of or applying and printings |

1.8 - 6 | |

| Applicator Number of wrap-arounds | 2 - 10 | |

| Applicator Speed of wrapping around u/sec | 3.0 | |

| Applicator Rolling on related to speed of wrapping around% | 10 - 100 | |

| Start | automatically, as soon as an item has been inserted by hand | |

| or via data interface | ||

| or via I/O interface | ||

- 1.5 mm diameter after sampling and release

![]() .

.

| Label printer | SQUIX 4/MP | |

|---|---|---|

| Material guiding | centered | |

| Print method | thermal transfer | |

| Print resolution dpi | 300 | 600 |

| Print speed mm/s max. | 200 | 150 |

| Print width mm max. | 105.7 | |

| Finishing Roll diametermm max. | 205 | |

| Finishing Roll Core diameter mm | 76 | |

| Pos. | Part no. | Label printer | |

|---|---|---|---|

| 1.1 |  |

5977007 5977008 |

SQUIX 4/300MP label printer SQUIX 4/600MP label printer |

| Pos. | Part no. | Applicator | |

|---|---|---|---|

| 2.1 | 5988000 | WICON wrap-around applicator Included in the accessory pack are -DR4-M30, DR4-M60 print rollers - WICON peel-off plate |

|

WLV wrap-around labels

All-around labeling

Data blocks capture the circumference of an item to the D1 diameter. Data blocks are partially covered in cases of smaller diameters.

Partial labeling

Protective laminate captures a data block to the D2 diameter.

Labels can be removed from the peel-off plate of a printer by hand or be applied by the wrap-around applicator directly onto items.

The properties of cab wrap-around labels are adapted to automated labeling using WICON, so is manufacture. All labels ‒ from the first to the last ‒ are applied precisely with the help of pretesion and retension. cab does not provide any functional warranty if third-party labels are in use.

Make sure item surfaces are clean and free of lubricants.

| Part no. | Data block | Item Ø | Label width W mm | Label height H mm | Data block height P mm | Labels / Roll | PU 1 Roll |

PU 2 Rolls in cardboard box |

||

|---|---|---|---|---|---|---|---|---|---|---|

| D min. mm |

D1 mm |

D2 mm |

||||||||

| 5780138.130 | white | 2.0* | 2.0 | 4.0 | 12.7 | 19.1 | 6.4 | 7,450 | 1 | 20 |

| 5780139.130 | white | 2.0* | 2.0 | 4.0 | 25.4 | 19.1 | 6.4 | 7,450 | 1 | 20 |

| 5780140.130 | white | 2.0* | 3.0 | 5.0 | 25.4 | 25.4 | 9.5 | 5,800 | 1 | 20 |

| 5780145.130 | white | 2.0 | 4.0 | 6.0 | 25.4 | 31.8 | 12.7 | 4,750 | 1 | 20 |

| 5780146.130 | white | 2.0 | 4.0 | 8.0 | 12.7 | 38.1 | 12.7 | 4,000 | 1 | 20 |

| 5780147.130 | white | 2.0 | 4.0 | 8.0 | 19.1 | 38.1 | 12.7 | 4,000 | 1 | 20 |

| 5780148.130 | white | 2.0 | 4.0 | 8.0 | 25.4 | 38.1 | 12.7 | 4,000 | 1 | 20 |

| 5780149.130 | white | 2.0 | 4.0 | 8.0 | 50.8 | 38.1 | 12.7 | 4,000 | 1 | 10 |

| 5780150.130 | white | 3.0 | 6.0 | 12.0 | 25.4 | 57.2 | 19.1 | 2,750 | 1 | 20 |

| 5780151.130 | white | 3.0 | 6.0 | 14.0 | 25.4 | 63.5 | 19.1 | 2,450 | 1 | 20 |

| 5780153.130 | white | 3.0 | 6.0 | 14.0 | 38.1 | 63.5 | 19.1 | 2,450 | 1 | 10 |

| 5780154.130 | white | 5.0 | 6.0 | 16.0 | 25.4 | 70.0 | 19.1 | 2,250 | 1 | 20 |

| 5780155.130 | white | 5.0 | 6.0 | 16.0 | 50.8 | 70.0 | 19.1 | 2,250 | 1 | 10 |

*1.5 mm diameter after sampling and release

Further sizes and colors can be provided upon request, so can labels free of halogen.

Ribbons

Ribbons

One ribbon roll serves for printing two rolls of wrap-around labels.

| Part no. | Width mm | Length m | PU 1 Roll |

PU 2 Rolls in cardboard box |

|---|---|---|---|---|

| 5557402.133 | 55 | 360 | 1 | 10 |

Thickness

Adhesive

Application temperature

Service temperature

Operation

Resistances

Approval

Roll finishing

80 μm

permanent

+15 to +35 °C

-40 to +80 °C, relative humidity of 60 to 85%

indoor, outdoor

water, dirt, petrol, oils, alcohol, detergents, UV light

UL 969A ‒ UL File Number MH66033

Outside diameter max. 205 mm

core diameter 76 mm

April 2024