Major discipline for Hermes+

Labeling fruit and vegetables in the flying change at Pakstation Venlo

Tomatoes, peppers, lemons, zucchini, packed in nets or portioned in plastic trays and sealed in foil are classic displays in retail and wholesale. Pakstation in Venlo ensures that the organic products are packed. The Weyers Group company owns a packing hall in the Fresh Park, a 130 hectare industrial estate for companies that are at home in the food sector. Fruit and vegetables from the company’s own cultivation areas in the nearer surrounding as well as from Belgium, Spain and Israel are delivered loose to Pakstation Venlo, where they are sorted and packed by machine. They all leave Venlo on trucks, with destination to customers mainly in Germany.

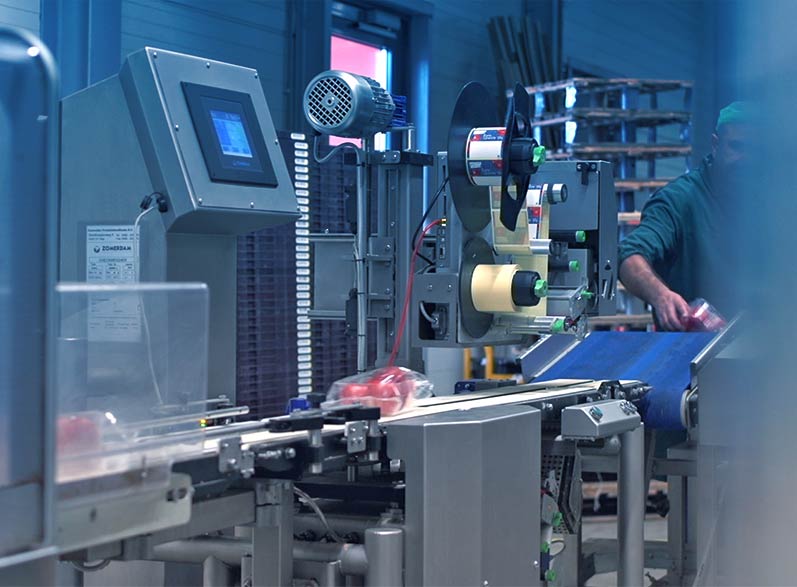

Once packed, the natural products are fully automatically labeled by systems including Hermes+ printers. The printers have been expanded with label transfer modules and application-specifically integrated in the packing lines by Zomerdam, a Dutch systems integrator and cab partner. Combined with, for example, checkweighers and counting systems, compact, technically and economically reasonable solutions have been established at Pakstation Venlo.

Double pack

In the interior packing hall, a sweet fragrance fills the air. 5,000 square metres floor space incorporate several packing lines. Here, the most modern machines transport, count and weigh fruit and vegetables and slide them into nets or foils without causing them damage. In the matter of labeling, two Hermes+ print and apply systems have been assembled in each packing line: one of the systems in classical manner, the other one upside down. By this, goods in motion can be labeled both from top and below.

Blast of air and vacuum belt labeling

Robbert Assmann, Zomerdam Service Technician, explains the ways the labels are applied: In case of package labeling from the top, the printed label is taken over by a transfer module in front of the peel-off plate of Hermes+. It is moved above the package. Without having any contact to the surface of the package, the label is blown onto the package from several centimeters distance with a strong blast of air. No pressure is exerted to the fruit or vegetables. For labeling from below onto a package, the Hermes+ have been installed upside down below the conveyor belt of a line. A vacuum belt moves the printed label to the peel-off position. As the goods pass through, the label rolls onto the package. The positioning of a label is sensor-controlled. At the end of each packing line, the packed and labeled products are picked up by employees and put into containers.

- Printing labels „on the fly“

Variable weighing data is sent to the printer within fractions of a second and finally printed on the label.

Labeling of fruit and vegetables with printers and labeling systems provided by cab and Zomerdam: What are the experiences of Pakstation Venlo so far? The Assistant Manager Jack Martens answered our questions.

Why are peppers and co. labeled?

Martens: A package label displays all the information of a product. What article is included? Where does it come from? What is the filling volume? Consumers have to rely on the commercial categories that are mentioned on the label, as well as its relating quality criteria.

What requirements does Pakstation Venlo derive on the printers and labeling systems?

Martens: As we are a manufacturing company, devices have to be of the highest quality, working free from errors with heavy load. They have to be flexible, with only short setup times when switching to a new print job with a new label.

- Clearly readable information

Law defines what has to be indicated on fruit packaging.

How did you get in contact with cab?

Martens: The beginning of our cooperation dates back many years. At first, there were desktop printers with which we printed labels for our transport containers. They did pretty well. So we took another step four years ago and together with Zomerdam installed the first two Hermes+ print and apply systems into our packing lines. In spring 2016, further four Hermes+ followed. At present, twelve such systems are in use in a total of six packing lines. We keep a fully configured additional device in reserve in case of a replacement.

How is a print job triggered?

Martens: Our customers define the fruit quantities resp. weights to be packed. For example, 500 grams of traypacked panicle tomatoes are ordered in a phone call or email. Related to the customer, the product is assigned a part number and a PLU code for identification in our database. We create a label with all the basic information and assign it to the part number. In case the customer orders this product again, employees on a PC can immediately select the label according to the part number and assign it directly from the database to the printing system as a print job.

This sounds like speed is the king ...

Martens: You are right. Our goal is to make 60 or 100 packings per minute instead of 30, if necessary. The labels have to be attached clearly visible and the information on the label has to be clearly readable. The cab devices meet these criteria, which makes us very happy. In a close dialogue with cab and Zomerdam we are constantly looking for improvements. We aim to further increase the clock rate at the packing stations in the future.

- Pictured left: Jack Martens; right: Robbert Assmann

Video of this application

Fruit and vegetable labeling with cab printers and labeling systems at Pakstation Venlo.

Products in use

Print and apply systems Hermes+

October 2018

www.weyersgmbh.de/en/pakstation

www.weyersgmbh.de/en/pakstation