Häussler baking village

Tradition meets modern

Karl-Heinz Häussler deals with grinding, kneading and baking. In the company‘s own baking village, around 100 employees design, manufacture and sell high-quality woodburning ovens and cookers, dough kneading machines, pasta makers and grain mills.

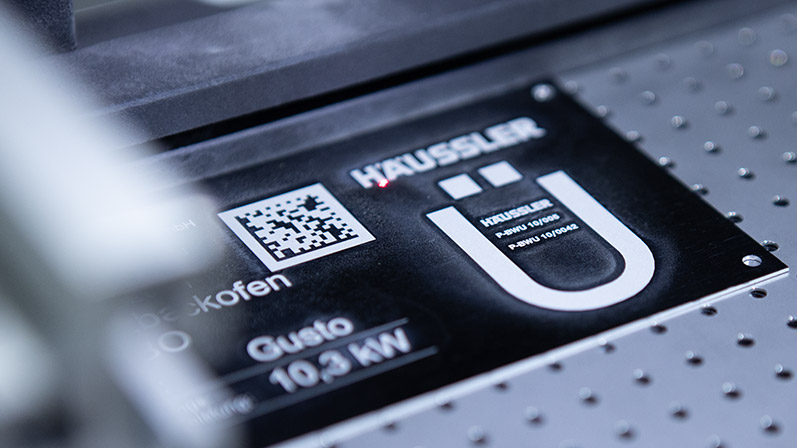

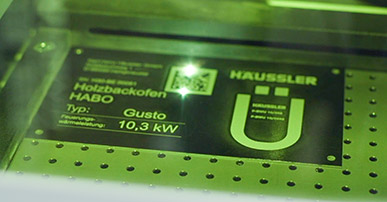

Hobby bakers and professionals find guidance and inspiration in baking lessons and seminars. Every unit circulated by Häussler must be clearly identified in accordance with industry regulations. The typeplates are marked in reliable manner by cab products XENO 1 and SQUIX 4, either by laser on aluminum or printed on silver self-adhesive labels.

“Quality is the best form of advertising” is written under the roof of the manufacturing hall. Häussler products are well-known for persistence, constructed on a high level of workmanship. According to the company, Häussler units are doing their job for 30 or more years, depending on use and care. The helpers for baking bread, pizza or pastries, noodles, filled pasta squares etc. find use in bakeries and catering, village communities, schools and kindergartens, but most of all in private households.

Machinery directive

- When marking with a fiber laser, the core of a glass fiber forms the laser-active medium.

Ovens, dough machines and pasta makers each require proof of conformity with essential demands of health and safety, and a typeplate. Consumer protection, quality assurance and traceability are aspects. Labels display a manufacturer, model, year of manufacture, article or serial numbers, for example. Labeling requirements differ. “Plates on ovens”, says Authorized Signatory Elmar Kornwachs, “must resist heat. Dough kneading machines, however, have their place in a kitchen and demand rather small plates.”

- Flawless! Elmar Kornwachs (pictured center) in talks with technical cab consultants Wolfgang Bayerle (laser marking, left) and Detlef Buder (label printing).

Moving ahead with cab

Mr. Kornwachs first contacted cab in October 2022. At that time, Häussler had a cab A4+ label printer in use from an earlier time and had always been satisfied with it. This led to an extended requirement. Serial numbers were to be displayed on each typeplate using a DataMatrix code. “By this,” affirms Mr. Kornwachs, “products in our warehouse can be clearly assigned to a customer before delivery.” A workshop was held with cab in Backdorf. On the cab side, one technical consultant each for laser marking and labeling took part. “At our first meeting,” recalls Mr. Kornwachs, “it quickly became clear that we would find a good solution together.” Since, plates resistant to heat have been put into practice by a XENO 1 laser marking system, while silver labels are printed by a SQUIX 4 thermal transfer printer.

Laser marking

A fiber laser is economical in particular when it comes to precise and durable top marking and a long life span of the marking system. Optimally matched to the application, Häussler achieves a high level of efficiency. Further benefits include focusability on smallest spaces and high processing speeds. No mechanical stress is exerted on the metal parts. In addition, laser data resists wear, light and extreme temperatures and therefore also suits for outdoor use.

- SQUIX 4 has printed a first line in less than a second subsequent to a printing trigger.

Label printing

In terms of cab label printing systems, the conjunction of an intelligent firmware, lean designed JScript programming language developed in-house and a highly performant CPU results in rapid processing. Print jobs can be entirely triggered, controlled and monitored via the cablabel S3 software, and label layouts be designed individually.

SQUIX 4 is a thermal transfer printer. This enables high print resolution and contrast and sharp-edged images. Even tiny text can be verified by eye or scanners. Printed materials resist mechanical influences, water or solvents. Specific data remain visible at any time. Codes and numbers are utilizable during processing and longterm stock.

High level of customer satisfaction

According to Mr. Kornwachs, all is fine: “We can easily design new plates at short notice using the cab marking software. The devices are low maintenance. If we have any questions, Mr. Bayerle and Mr. Buder are there to help us or visit our premises. We have also had good experiences with phone support. Minor cases have been resolved to our utmost satisfaction under warranty.” Plans for the future foresee operating both marking systems with just one software. At present, cab is beta-testing this option.

Loyal to home for 76 years

In 1949, Karl Häußler founded a village blacksmith shop with horse shoeing in Heiligkreuztal/Upper Swabia. Expansion into a regional business specializing in agricultural machinery followed. In 1974 the company oven manufacturing branch was formed, to which it entirely dedicates since 1993. The production, warehouse, exhibition and oven park area was dedicated as “baking village” in 2006. The company is still family-owned, now in third generation. Picture: CEO Rosemarie Häußler.

www.backdorf.de/

July 2025