Marking of pharmaceutical bins with a Hermes+ system

Accuracy even when there is little space

VEBICODE – The first two syllables are composed of the family names of the two managing directors and company founders Sergio Ventura and Marco Bigiolli. „Code“ is for barcode. The company name indicates: VEBICODE for already 20 years specializes in the field of identification technologies. We have met with Marco Bigiolli at VEBICODE headquarter in Rapperswil in the Swiss canton St. Gallen. Our talk was pretty much on process reliability and fully automatic labeling. Specifically we talked about marking test tube carriers.

Mr. Bigiolli, as regards marking, no product is like the other – approval or contradiction?

Bigiolli: Definitely approval! When it comes to coding and marking, every industry has its own challenges.

Let us be more specific. What are the most important requirements in case of product marking?

Bigiolli: For example, environmental conditions may be difficult. There are continuous processes, rigid instructions, high-speed production lines and a bunch of products and types of packaging. That makes all such exiting.

Here and now the focus shall be on the pharmaceutical sector. Do you have at hand a practical example?

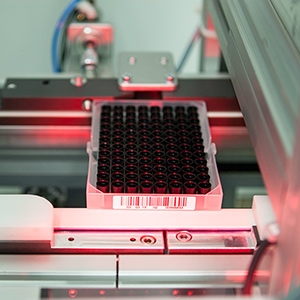

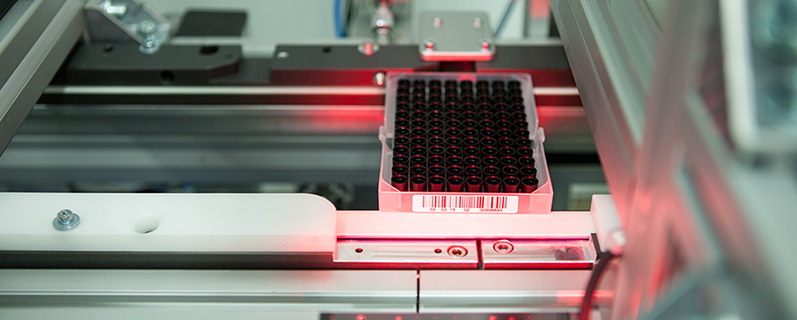

Bigiolli: Whether it is the pharmaceutical industry, medical technology or laboratory equipment – test tubes, Petri dishes and further acrylic glass products are ubiquitous. In this regard, we have just been contacted by an engineering office for a truly demanding customer project. It was about precisely applying 50x10 millimeter labels frontally to test tube carriers. These are racks, in which tubes with possibly important or even life-sustaining substances can be fixed. Since there is only little space at which the label can be applied a marking system was needed that copes with little tolerances.

What solution has been chosen?

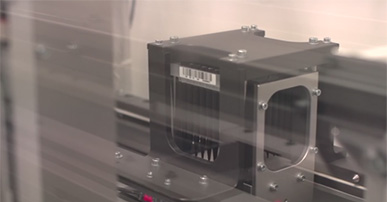

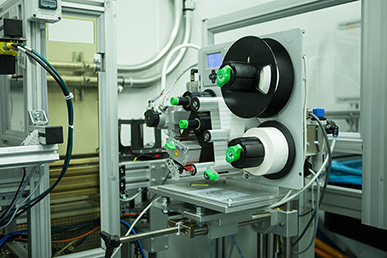

Bigiolli: First of all we are a retailer for cab label printing and applying systems. These are high quality. Due to a comprehensive portfolio of products and accessories as well as the close collaboration with cab we are able to live up to individual customer demands. This is a very important criterion for us! In the present case we have opted for a cab Hermes+4 print and apply system with swing applicator 3214 and a special pad. The Hermes+ is specifically designed for fully automatic printing and applying for example in production lines.

-

Work station with a cab Hermes+ system

-

The applicator 3214 picks up the printed label to apply it to the product.

As you have mentioned „fully automatic marking”: How is the label applied to the test tube carrier?

Bigiolli: I tell you. Applying with the applicator 3214 is from the side. The pad at the applicator is positioned in front of the peeloff edge. The label is picked up while printing. A rotating cylinder turns to the labeling position. The label is then positioned onto the test tube carrier via a stroke cylinder. Both pivoting angle and linear stroke are individually adjustable. As you can see, the application of the label to this not commonplace product is fully automatic and precise. Works perfect!

Products in use

Print and apply system Hermes+

© cab 05/2015