Bavaria Digital Technik

Electronics from a single source

Pfronten in the geographical Allgäu region, gateway to the Alps: This is where BDT develops, manufactures and distributes electronic components, assemblies and systems ready-for-use in data acquisition, recording and control technology. BDT stands for Bavaria Digital Technik GmbH. The company accompanies many customer projects from the initial idea to fully assembled delivery, whether it is prototyping or serial manufacture, hardware or software, project planning, mechanical engineering, testing, approval, logistics or service.

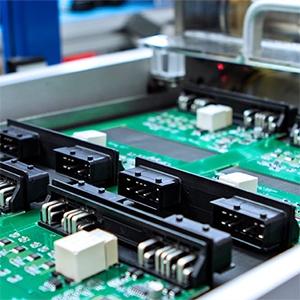

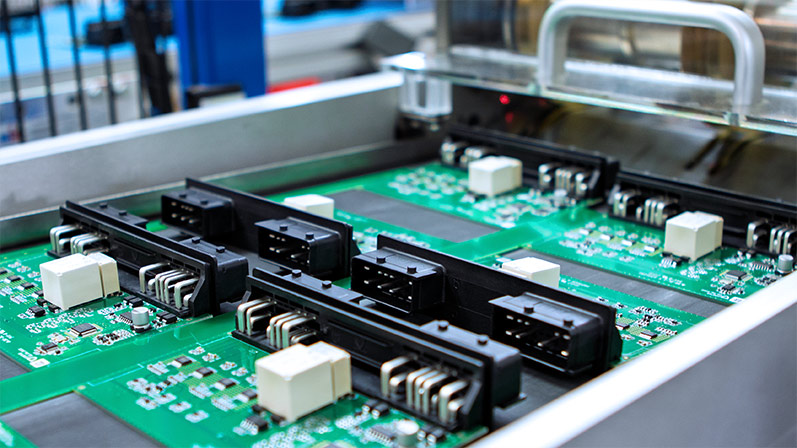

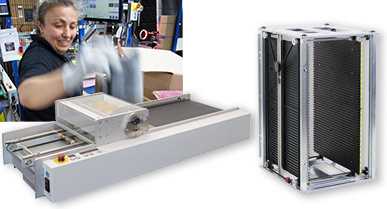

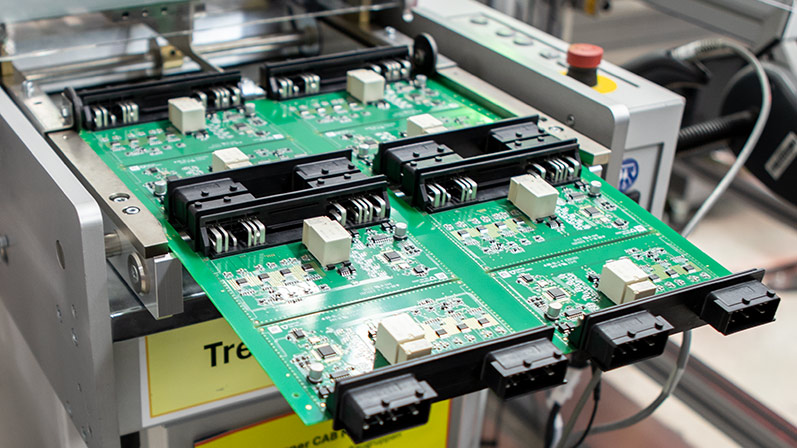

At the company warehouse, about 50 cab series 700 magazines are stacking PCB panels for safe transport and further steps of manufacture. Within the processing and assembly lines, cab MAESTRO 5 units are separating PCB precisely with low stress.

PCB transport

Reliable processes, ruggedness, stability and easy handling are major requirements posed by BDT on the use of PCB magazines. cab units can do all these. They are made of electrically conductive plastics. Torsion-resistance supports continuous operation. Low weight and tool-rounded edges enable the magazines been carried by hand without risk.

When operating different PCB sizes, the magazines can be aligned to new widths using a toothed belt. For use in plants with higher-level control, in which loaders transport PCB, cab offers magazines whose moveable side walls adjust automatically when being placed onto the loader.

Separation of PCB

- Locks on the front and back of a magazine prevent PCB in slots from damage.

In electronics, a panel refers to several PCB arranged on a carrier. It is crucial to minimize mechanical stress when separating the PCB. Sensitive components such as microcontrollers or capacitors must not be damaged. MAESTRO PCB separators operate with low stress thanks to precisely guided circular and linear blades. BDT benefits from the persistence and consistent quality of the assembled PCB.

At BDI, lots of an order can comprise as many as 5,000 PCB. The MAESTRO 5 unit is particularly economical when separating pre-scored PCB in large quantities. A maximum of 15 PCB in multiple-use panels can be separated simultaneously. The number of circular blades and their spacing are selected according to a PCB. Stable and precisely manufactured blade shafts make up top-notch cuts. The circular blades are hardened, grinded and coated with Titanium for high working capacity.

BDT employees insert the panels to the MAESTRO 5 guide. It would also be possible to feed panels automatically using a loader or an external conveyor. The base frame of MAESTRO 5 can be adjusted in height for any application. Separated PCB are transported on an integral conveyor.

- Multiple-use PCB panels are pulled in by MAESTRO 5 as wide as 310 millimeters.

Cobot, take control!

In further manufacturing steps, robots guide PCB through additional assemblies to BDT end products, such as modules for trailer monitoring in towing vehicles, PLC control in industrial electronics, nerve stimulation in medtech or protocol converters for combined heat and power stations.

- Gerd Atzler (left) and cab consultant Gerold Marsch are close to their customers at all times.

Harmonious synergy

Gerd Atzler is responsible for production engineering and maintenance at BDT. He recalls: “We got in contact with cab in 2008. At that time, our incoming goods department had cab label printers in use and had always been satisfied.” This led to an extended requirement for the electronics manufacturing department. A PCB separator was needed that met BDT‘s demands for efficiency and ease of use. “The initial contact,” Mr. Atzler adds, “proved to be particularly valuable for us. During the meeting, we quickly got aware of the potential of cab solutions for our processes. We therefore decided to collaborate.”

Reliable partners on equal terms

BDT has always been satisfied with the partnership. The units can be handled straightforward, free of complex programming. Durable equipment results in trouble-free manufacturing. Gerold Marsch as a technical consultant and cab‘s phone support provide competent and quick assistance when needed. “For BDT, cab has long been more than just a supplier,” says Mr. Atzler: “A powerful partner on equal terms.”

Then and now

Rolf Müller founded the company in 1969 with two employees. From a pure supplier of automation technology for printing machines, it gradually developed into a specialist in electronics production. Its focus is on the automotive industry, industrial electronics, medical technology and specific solutions dedicating to sustainable energies. Today, BDT employs 130 people. Since 2006, the company has been part of AdCapital Industrieholding.

www.bdt-online.de

Video of this operation

Case study Bavaria Digital Technik: Electronics from a single source

September 2025