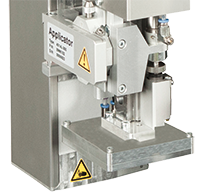

Stroke applicators HQ 4014 for linerless

Labels are applied in real time preferably onto packages

The type of pad defines whether a package has to be at rest or may be in motion at the time a label is applied. Labels can be applied from all sides.

The pad locates in front of the peel-off plate. Printed labels are taken over and set onto packages by a stroke cylinder. A sensor detects each package and triggers the pad to its initial position.

The length of the stroke cylinder defines the maximum distance of a package to the peel-off plate.

Accessories

5.13 Blow tube

5.14 Unit to regulate compressed air

Options

5.17 Pressure-reducing valve

5.18 Reduced-force applicator

with tamp-on pad, universal pad, tamp-on pad spring-mounted, universal pad spring-mounted

| Stroke applicators | HQ 4014L/R-200 | HQ 4014L/R-300 | HQ 4014L/R-400 | HQ 4014L/R-600 |

|---|---|---|---|---|

| Package height variable |  |

|||

| State of a packageat rest at the moment a label is applied |

|

|||

| Direction from which labels are applied | from the top, from below, from the side | from the top, from below |

||

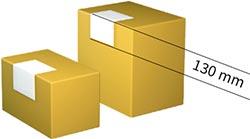

| Distance of a package to the bottom of the unit mm max. | 130 | 230 | 330 | 530 |

| Weight of applicator packaging excluded kg | 5 | 5 | 7 | 9 |

| Consumption of power W max. | 15 | |||

| Compressed air bar | 4.5 | |||

| Cycle rate1) labels/min approx. | 25 | |||

Tamp-on pad

Labels are precisely tamped onto plane, even recessed, surfaces.

Universal pad

Labels are tamped onto flat surfaces. Drilled vacuum holes (in gaps of 5 mm) for sucking labels are covered by sliding foil and can be opened according to a label size using a perforation tool. Delivery includes two extra foils for replacement.

Tamp-on pad, spring-mounted

Labels are applied onto surfaces inclined as much as 15° using a spring-mounted vacuum plate. Height within a label area may vary by 10 mm.

Universal pad, spring-mounted

Labels are applied onto surfaces inclined as much as 15° using a spring-mounted vacuum plate. Height within a label area may vary by 10 mm. Drilled vacuum holes (in gaps of 5 mm) for sucking labels are covered by sliding foil and can be opened according to a label size using a perforation tool. Delivery includes two extra foils for replacement.

| Tamp-on pad | Universal pad | Tamp-on pad, spring-mounted | Universal pad, spring-mounted | |

| Transfer module | 4014 L/R 11 F | 4014 L/R 1100 | 4014 L/R 3100 | 4014 L/R 3100 |

|---|---|---|---|---|

| Label width HERMES Q4.3 mm | 50 - 105 | 75 / 90 | 80 - 105 | 105 / 105 |

| Label height HERMES Q4.3 mm | 30 - 210 | 60 / 90 | 80 - 210 | 102 / 152 |

| Depth of a pad immersing F2) mm max. |

140 | - | - | - |

- on a cover HERMES QL2/QL4/QL4.3, dimension F standard 60 mm (100 mm an option, a maximum of 120 mm upon r equest)

with blow-on pad, roll-on pad, corner-wrap pad

| Stroke applicator | HQ 4014L/R-200 | HQ 4014L/R-300 | HQ 4014L/R-400 | HQ 4014L/R-600 |

|---|---|---|---|---|

| State of a package at theat rest moment a label is appliedin motion |

Blow-on pad, corner-wrap pad | |||

| Blow-on pad, roll-on pad | ||||

| Direction from which from the top from belowlabels are applied from the side |

Blow-on pad, roll-on pad, corner-wrap pad | |||

| Blow-on pad, roll-on pad | ||||

| Blow-on pad, roll-on pad | - | |||

| Distance of a package to the bottom of a unit Blow-on pad mm max. Roll-on pad mm max. Corner-wrap pad mm max. |

140 |

240 |

340 |

540 |

| 160 | 260 | 360 | 560 | |

| 100 | 200 | 300 | 500 | |

| Package heightuniform variable |

Blow-on pad | |||

| Blow-on pad, corner-wrap pad | ||||

| Weight of applicator packaging excluded kg | 5 | 5 | 7 | 9 |

| Consumption of power W max. | 15 | |||

| Compressed airbar | 4.5 | |||

| Cycle rate1) labels/min approx. | 25 | |||

Blow-on padLabels are blown onto sensitive surfaces or packages in motion by a blast of air. Distances of 5 mm to 10 mm to of a package are set by a stop on the stroke cylinder.

Roll-on pad

Labels are rolled onto plane packages in motion.

Corner-wrap pad

Labels are applied to two adjacent sides of a package. The pad applies the first half of a label onto the top of the package. The second half is then rolled on.

| Blow-on pad | Roll-on pad | Corner-wrap pad | |

| Transfer module | 4014 L/R 2100 | 4014 L/R 4100 | 4014 L/R 5100 |

|---|---|---|---|

| Label width HERMES Q4.3 mm | 50 - 105 | 50 - 105 | 50 - 105 |

| Label height HERMES Q4.3 mm | 30 - 100 | 80 - 250 | 60 - 210 |

Pressure-reducing valve

It reduces the pressure exerted by the stroke cylinder to a product.

Pressure-reduced applicator

It has been designed for manual workstations missing a protective cover. The cylinder diameter is reduced to 12 mm.

To prevent from injuries, a safety valve limits compressed air to a maximum of 4.8 bar.

3D models for this applicator in STEP format you can find in documentation of HERMES Q.

Documentation

-

Catalogs

-

Title Format Version Last change Language HERMES Q with HQ applicators

PDF - 6.39 MB 04/2025 17/04/2025 English HERMES QL with HQ / HQI applicators

PDF - 3.44 MB 06/2025 23/06/2025 English

-

-

Assembly Instructions

-

Title Format Version Last change Language Assembly Instructions Stroke applicator HQ 4014 / HQ 4016

PDF - 2.81 MB 02/2025 14/02/2025 English -

Other languages

-

Title Format Version Last change Language Montageanleitung Hubapplikator HQ 4014 / HQ 4016

PDF - 2.34 MB 02/2025 14/02/2025 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List Stroke applicator HQ 4014, HQ 4016

Spare Parts List Stroke applicator HQ 4014, HQ 4016PDF - 1.05 MB 04/2025 10/07/2025 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste Hub-Applikator HQ 4014 / HQ 4016

PDF - 904 KB 04/2025 10/07/2025 Deutsch

-

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Software & Drivers

-

Firmware periphery

-

Title Format Version Last change Language Firmware applicators SQ, HQ

ZIP - 49 KB 2.1.0 08/04/2025 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader