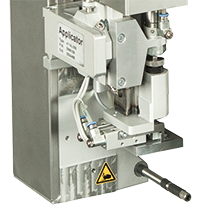

Stroke applicators HQ 4114, HQ 4116

Labels very small or midsized can be applied in real time from all sides

The pad locates in front of the peel-off plate. It picks up a label while it is being printed. Powered by a short stroke cylinder, the pad is brought into position in horizontal direction. The label is transferred to a product by a stroke cylinder. The length of the stroke cylinder defines the maximum distance of a product to the peel-off plate.

Accessories

5.13 Blow tube

5.14 Unit to regulate compressed air

Options

5.17 Pressure-reducing valve

5.18 Reduced-force applicator

| Stroke applicators | HQ 4114 L/R-200 | HQ 4114 L/R-300 | HQ 4114 L/R-400 | HQ 4114 L/R-600 | HQ 4116 L/R-200 | HQ 4116 L/R-300 | HQ 4116 L/R-400 |

|---|---|---|---|---|---|---|---|

| Label applications | from the top, from below, from the side | ||||||

| State of a product at rest in motionat the moment a label is applied |

|

||||||

| only blow-on pad | |||||||

| Product heights uniform variable |

only blow-on pad | ||||||

| all tamp-on pads | |||||||

| Short stroke cylinder, horizontalmm | 10 | ||||||

| Distance of a product to the bottom of the unitup to mm | 135 | 235 | 335 | 535 | 135 | 235 | 335 |

| Weight of applicator packaging excluded kg | 5 | 5.5 | 7 | 9 | 5 | 6 | 7.5 |

| Consumption of power W max. | 15 | ||||||

| Compressed airbar | 4.5 | ||||||

| Cycle rate1) labels/min approx. | 30 | ||||||

Tamp-on pad

Labels are precisely tamped on plane surfaces. Recessed levels are possible as well.

Tamp-on pad, providing a damping layer

When applying labels to hard surfaces, the noise level is reduced. It benefits also in cases of rough structures or little unevenness.

Tamp-on pad, providing a label stop

It enables small labels be applied exactly on spot to a product.

Blow-on pad

It benefits when labels have to be applied to sensitive surfaces or products in motion. Labels are blown on by a blast of air. Stroke cylinder adjustment enables bridging distances of 5 to 10 mm to the surface of a product.

| Tamp-on pad | Tamp-on pad, providing a damping layer | Tamp-on pad, providing a label stop | Blow-on pad | |

| Transfer modules | 4114, 4116 L/R 11 F | 4114, 4116 L/R 12 F | 4114, 4116 L/R 61 F | 4114 L/R 2100 |

|---|---|---|---|---|

| Label widths HERMES Q2 mm Label widths HERMES Q4/Q4.3 mm Label widths HERMES Q6.3mm |

4 - 58 | 10 - 58 | 10 - 58 | 10 - 58 |

| 10 - 114 | 10 - 114 | 10 - 114 | 10 -114 | |

| 50 -174 | 50 -174 | 50 -174 | - | |

| Label heights HERMES Q2 mm Label heights HERMES Q4/Q4.3 mm Label heights HERMES Q6.3mm |

4 - 80 | 8 - 80 | 4 - 80 | 10 - 80 |

| 8 - 80 | 8 - 80 | 8 - 80 | 10 - 80 | |

| 8 - 80 | 8 - 80 | 8 - 80 | - | |

| Depth of a pad immersing F2) up to mm | 130 | 130 | 130 | - |

- On the cover HERMES Q2/Q4/Q4.3 cut-out dimension F standard 60 mm, optional 100 mm, on r equest up to 110 mm

On the cover HERMES Q6.3 cut -out dimension F standard 25 mm, on request up to 110 mm

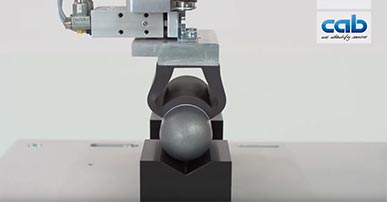

Form pad

Labels are precisely applied to cylindric objects, inclined or curved surfaces. Curved form pads prevent from blistering on very smooth and plane surfaces. 200° maximum label wrapping on cylindric objects

Accessories

5.13 Blow tube

5.14 Unit to regulate compressed air

| Form pad | |

| Transfer module | 4114, 4116 L/R 8800 |

|---|---|

| Label widths HERMES Q2 mm Label widths HERMES Q4/Q4.3 mm Label widths HERMES Q6.3mm |

4 - 58 |

| 10 - 114 | |

| 50 -174 | |

| Label heights mm | 8 - 80 |

Video: Hermes Q with applicator 4114 and form pad

Labels are applied precisely to cylindric objects, oblique or curved surfaces.

Pressure-reducing valve

It reduces the pressure exerted by the stroke cylinder to a product.

Pressure-reduced applicator

It has been designed for manual workstations missing a protective cover. The cylinder diameter is reduced to 12 mm.

To prevent from injuries, a safety valve limits compressed air to a maximum of 4.8 bar.

Video: labelling of electronic components with applicator 4114

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- Labelling of electronic components with applicator 4114 (MPEG-4, 26 MB)

Video: Hermes Q with applicator 4114 and silicone form pad

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- Hermes Q with applicator 4114 and silicone form pad (MPEG-4, 52,9 MB)

Video: Hermes+ with applicator 4114 and silicone form pad

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- Hermes+ with applicator 4114 and silicone form pad (MPEG-4, 9,1 MB)

Video: Hermes+ stroke applicator 4114

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- Hermes+ stroke applicator 4114 (MPEG-4, 1,5 MB)

- Hermes+ stroke applicator 4114 (WMV, 5 MB)

Download players:

- For WMV: Windows Media Player

- For MPEG-4: VLC Player

3D models for this applicator in STEP format you can find in documentation of HERMES Q.

Documentation

-

Catalogs

-

Title Format Version Last change Language HERMES Q with HQ applicators

PDF - 6.39 MB 04/2025 17/04/2025 English

-

-

Operation Manuals

-

Title Format Version Last change Language Operator's Manual System HERMES Q and Stroke Applicator HQ 4114 / HQ 4116 power reduced

PDF - 7.12 MB 03/2025 21/05/2025 English

-

-

Assembly Instructions

-

Title Format Version Last change Language Assembly Instructions Stroke applicator HQ 4114 / HQ 4116

PDF - 2.63 MB 02/2025 04/03/2025 English -

Other languages

-

Title Format Version Last change Language Montageanleitung Hubapplikator HQ 4114 / HQ 4116

PDF - 1.98 MB 02/2025 12/02/2025 Deutsch Notice d'assemblage Applicateur d'étiquettes de petites tailles HQ 4114 / HQ 4116

PDF - 1.85 MB 02/2025 26/03/2025 Français

-

-

-

Service Manuals

-

Title Format Version Last change Language Service Manual Stroke Applicator HQ 4114 / HQ 4116

PDF - 5.81 MB 03/2025 14/04/2025 English -

Other languages

-

Title Format Version Last change Language Serviceanleitung Hubapplikator HQ 4114 / HQ 4116

PDF - 5.66 MB 03/2025 04/03/2025 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List Stroke applicator HQ 4114, HQ 4116

PDF - 1.05 MB 04/2025 24/04/2025 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste Hub-Applikator HQ 4114 / HQ 4116

PDF - 1.06 MB 04/2025 24/04/2025 Deutsch

-

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Software & Drivers

-

Firmware periphery

-

Title Format Version Last change Language Firmware applicators SQ, HQ

ZIP - 49 KB 2.1.0 08/04/2025 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader