Stroke applicators HQ 4014, HQ 4016

Labels can be applied in real time from all sides to packages

The type of pad defines whether a package has to be at rest or can be in motion at the time a label is applied.

The pad locates in front of the peel-off plate. It picks up a label while it is being printed. The label is transferred to a package with the help of a stroke cylinder. The package is detected by a sensor and the pad returned to its initial position.

The length of the stroke cylinder defines the maximum distance of a package to the peel-off plate.

Accessories

5.13 Blow tube

5.14 Unit to regulate compressed air

Options

5.17 Pressure-reducing valve

5.18 Reduced-force applicator

with tamp-on pad, universal pad, tamp-on pad spring-mounted, universal pad spring-mounted

| Stroke applicators | HQ 4014L/R-200 | HQ 4014L/R-300 | HQ 4014L/R-400 | HQ 4014L/R-600 |

HQ 4016L/R-200 | HQ 4016L/R-300 | HQ 4016L/R-400 | HQ 4016L/R-600 |

|---|---|---|---|---|---|---|---|---|

| Package heights variable |  |

|||||||

| State of a packageat rest at the moment a label is applied |

|

|||||||

| Label applications |

from the top, from below, from the side | from the top, from below |

from the top, from below, from the side | from the top, from below |

||||

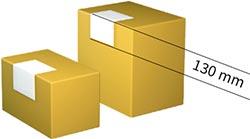

| Distance of a package to the bottom of the unit up to mm | 130 | 230 | 330 | 530 | 130 | 230 | 330 | 530 |

| Weight of applicator packaging excluded kg | 5 | 5 | 7 | 9 | 5 | 5.5 | 7.5 | 9.5 |

| Consumption of power W max. | 15 | |||||||

| Compressed air bar | 4.5 | |||||||

| Cycle rate1) labels/min approx. | 25 | |||||||

Tamp-on pad

Labels are precisely tamped on plane surfaces. Recessed levels are possible as well.

Universal pad

Labels can be tamped on plane surfaces. Drilled holes are provided in gaps of 5 mm to suck a label. The holes are covered by a sliding foil, but can be opened according to the size of a label using a punching tool. Delivery includes two extra foils.

Tamp-on pad, spring-mounted

Labels can be applied to surfaces inclined by a maximum of 15°. Heights witin the area of a label may vary by 10 mm at most.

Universal pad, spring-mounted

Labels can be applied to surfaces inclined by a maximum of 15°. Heights in the area of a label may vary by 10 mm at most. To suck a label, drilled holes are provided in gaps of 5 mm and covered by a sliding foil. Delivery includes two extra foils.

| Tamp-on pad | Universal pad | Tamp-on pad, spring-mounted | Universal pad, spring-mounted | |

| Transfer modules | 4014, 4016 L/R 11 F | 4014 L/R 1100 | 4014, 4016 L/R 3100 | 4014 L/R 3100 |

|---|---|---|---|---|

| Label widths HERMES Q4/Q4.3 mm Label widths HERMES Q6.3 mm |

20 - 114 | 75 / 90 | 80 - 114 | 116 / 116 |

| 50 - 174 | - | 80 -174 | - | |

| Label heights HERMES Q4/Q4.3 mm Label heights HERMES mmQ6.3 |

20 - 210 | 60 / 90 | 80 - 210 | 102 / 152 |

| 25 - 210 | - | 80 - 210 | - | |

| Depth of a pad immersing F2) up to mm | 140 | - | - | - |

- On the cover HERMES Q2/Q4/Q4.3 cut-out dimension F standard 60 mm, optional 100 mm, on request up to 120 mm

On the cover HERMES Q6.3 cut -out dimension F standard 25 mm, on request up to 120 mm

withblow-on pad, roll-on pad, corner-wrap pad

| Stroke applicators | HQ 4014L/R-200 | HQ 4014L/R-300 | HQ 4014L/R-400 | HQ 4014L/R-600 | HQ 4016L/R-200 | HQ 4016L/R-300 | HQ 4016L/R-400 | HQ 4016L/R-600 |

|---|---|---|---|---|---|---|---|---|

| State of a package at theat rest moment a label is appliedin motion |

Blow-on pad, Corner-wrap pad | |||||||

| Blow-on pad, Roll-on pad | ||||||||

| Label applications from the top from below from the side |

Blow-on pad, Roll-on pad, Corner-wrap pad | |||||||

| Blow-on pad, Roll-on pad | ||||||||

| Blow-on pad, Roll-on pad | - | Blow-on pad, Roll-on pad | - | |||||

| Distance of a package to the bottomBlow-on pad up to mm of the unit Roll-on pad up to mm Corner-wrap pad mm |

140 | 240 | 340 | 540 | - | - | - | - |

| 160 | 260 | 360 | 560 | 160 | 260 | 360 | 560 | |

| 100 | 200 | 300 | 500 | - | - | - | - | |

| Package heightsuniform variable |

Blow-on pad | |||||||

| Blow-on pad, Corner-wrap pad | ||||||||

| Weight of applicator packaging excluded kg | 5 | 5 | 7 | 9 | 5 | 5.5 | 7.5 | 9.5 |

| Consumption of power W max. | 15 | |||||||

| Compressed airbar | 4.5 | |||||||

| Cycle rate1) labels/min approx. | 25 | |||||||

Blow-on pad

It benefits when labels have to be applied to sensitive surfaces or packages in motion. Labels are blown on by a blast of air.

Stroke cylinder adjustment enables bridging distances of 5 to 10 mm to the surface of a package.

Roll-on pad

Labels are rolled on plane surfaces while these packages are in motion.

Corner-wrap pad

Labels are applied to a package on two sides adjacent to one another. One half of a label is applied to the top of a package. Then the other half of the label is rolled on.

| Blow-on pad | Roll-on pad | Corner-wrap pad | |

| Transfer modules | 4014 L/R 2100 | 4014, 4016 L/R 4100 | 4014 L/R 5100 |

|---|---|---|---|

| Label widths HERMES Q4/Q4.3 mm Label widths HERMES Q6.3 mm |

20 - 114 | 25 - 114 | 20 - 114 |

| provided upon request | 50 - 174 | - | |

| Label heights HERMES Q4/Q4.3 mm Label heights HERMES mmQ6.3 |

20 - 100 | 80 - 250 | 60 - 210 |

| provided upon request | 80 - 250 | - |

Pressure-reducing valve

It reduces the pressure exerted by the stroke cylinder to a product.

Pressure-reduced applicator

It has been designed for manual workstations missing a protective cover. The cylinder diameter is reduced to 12 mm.

To prevent from injuries, a safety valve limits compressed air to a maximum of 4.8 bar.

Video: Hermes+ Applicator 4014 (roll-on pad)

Powered by YouTube. See all cab videos: cab Channel auf YouTube.

Other formats

- Hermes+ Applicator 4014 (roll-on pad) (MPEG-4; 6,6 MB)

Video: Hermes+ with stroke applicator 4014 and blow pad

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- Hermes+ with stroke applicator 4014 and blow pad (MPEG-4, 80,6 MB)

- Hermes+ with stroke applicator 4014 and blow pad (WMV, 50,8 MB)

Case study: Hermes+ systems label hazardous goods at ROSSMANN‘s central warehouse

Powered by YouTube. See all cab videos: cab Channel auf YouTube.

Video: Hermes+ with stroke applicator 4014 and blow pad

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- Hermes+ with stroke applicator 4014 and blow pad (MPEG-4, 80,6 MB)

- Hermes+ with stroke applicator 4014 and blow pad (WMV, 50,8 MB)

Video: Hermes+ with stroke applicator 4016 and universal pad

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- Hermes+ with stroke applicator 4016 and universal pad (MPEG-4, 2,3 MB)

- Hermes+ with stroke applicator 4016 and universal pad (WMV, 7,2 MB)

cab Video Tutorial: Assembly of the applicator 4016 in combination with the printer Hermes+ 6

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- cab Video Tutorial: Assembly of the Applicator 4016 in Combination with the Printer Hermes+ 6 (WMV, 90,7 MB)

- cab Video Tutorial: Assembly of the Applicator 4016 in Combination with the Printer Hermes+ 6 (MPEG-4, 16,7 MB)

Download players:

- For WMV: Windows Media Player

- For MPEG-4: VLC Player

3D models for this applicator in STEP format you can find in documentation of HERMES Q.

Documentation

-

Catalogs

-

Title Format Version Last change Language HERMES Q with HQ applicators

PDF - 6.38 MB 03/2026 06/03/2026 English

-

-

Operation Manuals

-

Title Format Version Last change Language Operator's Manual System HERMES Q and Stroke Applicator HQ 4014 / HQ 4016 power reduced

PDF - 7.20 MB 03/2025 21/05/2025 English -

Other languages

-

Title Format Version Last change Language Betriebsanleitung System HERMES Q und Hub-Applikator HQ 4014 / HQ 4016 kraftreduziert

PDF - 6.81 MB 03/2025 21/05/2025 Deutsch

-

-

-

Assembly Instructions

-

Title Format Version Last change Language Assembly Instructions Stroke applicator HQ 4014 / HQ 4016

PDF - 2.81 MB 02/2025 14/02/2025 English -

Other languages

-

Title Format Version Last change Language Montageanleitung Hubapplikator HQ 4014 / HQ 4016

PDF - 2.34 MB 02/2025 14/02/2025 Deutsch Notice d'assemblage Applicateur d'étiquettes standards HQ 4014 / 4016

PDF - 2.07 MB 02/2025 26/03/2025 Français

-

-

-

Service Manuals

-

Title Format Version Last change Language Service Manual Stroke Applicator HQ 4014 / HQ 4016

PDF - 4.81 MB 05/2025 23/05/2025 English -

Other languages

-

Title Format Version Last change Language Serviceanleitung Hubapplikator HQ 4014 / HQ 4016

PDF - 4.82 MB 05/2025 20/05/2025 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List Stroke applicator HQ 4014, HQ 4016

Spare Parts List Stroke applicator HQ 4014, HQ 4016PDF - 898 KB 03/2026 03/03/2026 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste Hub-Applikator HQ 4014 / HQ 4016

PDF - 904 KB 03/2026 03/03/2026 Deutsch

-

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Software & Drivers

-

Firmware periphery

-

Title Format Version Last change Language Firmware applicators SQ, HQ

SQ1000, SQ3200, HQ3014/3016, HQ3214, HQ4014/4016, HQ4024, HQ4114/4116, HQ4214, HQ4414, HQ4514, HQ4614, HQ6114ZIP - 52 KB 2.2.0 06/10/2025 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader