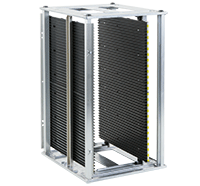

PCB magazines 600, 700, 800

Automation requires precision when magazines are in use in assembly lines.

1 Knobs for magazine stacking

2 Base and cover plates made of cast aluminum or sheet steel

3 Numbering along the PCB slots simplifies manual insertion.

4 Side walls made of conductive plastic or metal to be operated in ambient temperatures of 50 to 200°C

5 Transport lock A bar is mounted as a standard on the front and back sides.

Slots locked

Slots unlocked

Metal magazine

In the case of high mechanic force and high thermal force up to 200°C, metal side walls are provided.

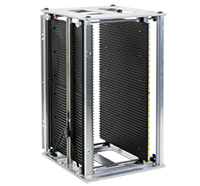

Safe stacking

All the magazines can be stacked safely and in a space-saving manner with the help of our knobs provided on the upper plate.

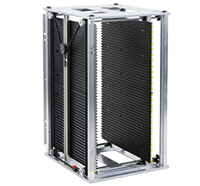

Perfecting operation

Its vertical symmetry allows the magazines to be turned upside down if use is in perfecting mode. To be operated only without stacking knobs

Series 600 - Screw-clamped width setting

Series 600 magazines are cost-effective. With the help of four screw clamps, the side wall can be set to the PCB width.

Series 700 - Variable width setting by pulling the gear belt by hand

By pulling the gear belt, the side walls are set to the PCB width.

Series 800 - Variable width setting by pulling the gear belt motor-driven or by hand

Automatic operation: When put on a loader, the bar is moved to the outside by a wedge. At removal, the slot locks again. Manual operation: At lifting by hand, the bar is moved to the outside and locks in upper position. When lifting again, the slots are locked.