PCB magazines

Series 6000, 7000

Consistent further development of series 600/700/800 magazines

Automation requires precision

Precision, stability and dimensional accuracy are key features when operating magazines in automated pick-and-place plants.

Ball-bearing precision spindles keep side panels synchronous along the entire range of alignment.

A rugged and torsion-resistant frame design enables long-term use in manufacture. Side panels are designed electrically conductive.

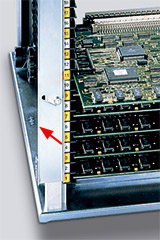

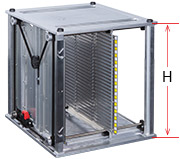

Picture: series 7000 magazine

1 Top covers and base plates are entirely closed to protect PCB.

2 Knobs for magazine stacking

3 Precision spindles for keeping side panels parallel

4 Transport lock

A latch is provided on the front and back of a fixed side panel. It unlocks by vertical lifting. Inclination causes the latch to slide aside.

Magazine locked

Magazine unlocked

Transport lock A

Transport lock A

for manual and automatic operation (no turnaround mode)

Transport lock B

Transport lock B

for turnaround operation

Transport lock C

Transport lock C

for operation in autonomous manufacturing lines

See further details see Accessories

5 Side panels

Three designs are provided. Choice depends on the ambient temperature. Consecutive numbering from 1 to 50 along the guides simplifies PCB insertion.

Reliable stacking

Four knobs on the top cover enable magazines be stacked reliably and save-spacing.

Turnaround operation

Vertical symmetry allows magazines be rotated by 180°. No use of stacking knobs

Metal magazine

In cases of high mechanic and high thermal force, metal side panels may be provided. Assembled without stacking knobs on delivery

Series 6000 PCB magazines

Widths set by hand using four screw clamps

1 Top covers and base plates are entirely closed to protect PCB.

1 Top covers and base plates are entirely closed to protect PCB.

Nothing can enter from above or below, Higher rigidity is another benefit.

2 PCB locking during transport

Partly assembled magazines have locks B enclosed separately upon delivery. Locks A or C are options.

3 Alignment to PCB

Side panels can be aligned to target PCB widths by loosening four screw clamps.

Series 7000 PCB magazines

Widths set by hand using a gear belt or motoric by clutch

1 Top covers and base plates are entirely closed to protect PCB.

1 Top covers and base plates are entirely closed to protect PCB.

Nothing can enter from above or below, Higher rigidity is another benefit.

2 Synchronous side panel setting

PCB widths are quick and accurate to align using four precision spindles and bearing free of backlash.

3 PCB locking during transport

Partly assembled magazines have locks A enclosed separately upon delivery. Locks B or C are options.

4 Alignment to PCB by hand

4A Pulling the gear belt

4B Fine control by turning a handwheel

5 Motoric alignment to PCB by clutch

Once a magazine is positioned on the unloader, a clutch connects the servo motor to the spindle gear.

6 Fixing a width setting

The gear belt is fastlocked. If aligning to a PCB width by hand, the clamp block is lifted by pressing and locked into place. The gear belt is again fixed by pressing the locking lever. In cases of motoric width setting, the clamp block is lifted by a plunger during positioning.

Series 6000 PCB magazines

Type |

Part no. |

Material | Temperature °C | Weight kg |

Outside dimensions | PCB | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Side panel |

Base plate |

Slide-ins |

Ambient |

Width W mm |

Length L mm |

Heigh H mm |

Width D mm |

Length C max. mm |

|||

| 6001.1 6001.2 6001.3 |

8917905 8918905 8919905 |

Polystyrene Polycarbonate Metal |

Cast aluminum | 60 130 200 |

50 100 200 |

5.6 5.9 6.9 |

320 | 355 | 563 | 40 - 250 | 342 |

| 6002.1 6002.2 6002.3 |

8917906 8918906 8919906 |

Polystyrene Polycarbonate Metal |

Cast aluminum | 60 130 200 |

50 100 200 |

5.8 6.1 7.2 |

320 | 400 | 563 | 40 -250 | 387 |

| 6003.1 6003.2 6003.3 |

8917907 8918907 8919907 |

Polystyrene Polycarbonate Metal |

Cast aluminum | 60 130 200 |

50 100 200 |

6.2 6.5 7.6 |

380 | 400 | 563 | 40 - 310 | 387 |

further dimensions upon request

| Scope of magazine delivery | |||

|---|---|---|---|

| Standard | Optional | ||

| partly assembled |

assembled |

assembled with stacking knobs Part no. |

assembled for turnaround operation Part no. |

- |

- -  |

DL31011 DL31011 - |

DL31012 DL31012  |

- |

- -  |

DL31011 DL31011 - |

DL31012 DL31012  |

- |

- -  |

DL31011 DL31011 - |

DL31012 DL31012  |

Standard

Standard

Series 7000 PCB magazines

Type |

Part no. |

Material | Temperature °C | Weight kg |

Outside dimensions | PCB | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Side panel |

Base plate |

Slide-in |

Ambient |

Width W mm |

Length L mm |

Hight H mm |

Width D mm |

Length C max. mm |

|||

| 7001.1 7001.2 7001.3 |

8917901 8918901 8919901 |

Polystyrene Polycarbonate Metal |

Cast aluminum | 60 130 200 |

50 80 100 |

5.6 5.9 6.9 |

320 | 355 | 563 | 40 - 250 | 342 |

| 7002.1 7002.2 7002.3 |

8917902 8918902 8919902 |

Polystyrene Polycarbonate Metal |

Cast aluminum | 60 130 200 |

50 80 100 |

5.8 6.1 7.2 |

320 | 400 | 563 | 40 -250 | 387 |

| 7003.1 7003.2 7003.3 |

8917903 8918903 8919903 |

Polystyrene Polycarbonate Metal |

Cast aluminum | 60 130 200 |

50 80 100 |

6.2 6.5 7.6 |

380 | 400 | 563 | 40 - 310 | 387 |

| 7004.1 7004.2 7004.3 |

8917904 8918904 8919904 |

Polystyrene Polycarbonate Metal |

Sheet steel | 60 130 200 |

50 80 100 |

7.8 8.0 9.5 |

400 | 460 | 563 | 40 - 330 | 447 |

| 7016.2 7016.3 |

8918916 8919916 |

Polycarbonate Metal |

Sheet steel | 130 200 |

80 100 |

9.5 10.9 |

460 | 535 | 563 | 10 - 390 | 522 |

| 7017.2 7017.3 |

8918917 8919917 |

Polycarbonate Metal |

Sheet steel | 130 200 |

80 100 |

9,7 11.1 |

530 | 535 | 563 | 10 - 460 | 522 |

further dimensions upon request

| Scope of magazine delivery | |||

|---|---|---|---|

| Standard | Optional | ||

| partly assembled |

assembled | assembled with stacking knobs  Part no. |

assembled for turnaround operation  Part no. |

- |

- -  |

DL31011 DL31011 DL31011 |

DL31012 DL31012 DL31012 |

- |

- -  |

DL31011 DL31011 DL31011 |

DL31012 DL31012 DL31012 |

- |

- -  |

DL31011 DL31011 DL31011 |

DL31012 DL31012 DL31012 |

- |

- -  |

DL31011 DL31011 DL31011 |

DL31012 DL31012 DL31012 |

- |

- |

DL31011 DL31011 |

DL31012 DL31012 |

- |

- |

DL31011 DL31011 |

DL31012 DL31012 |

Standard

Standard

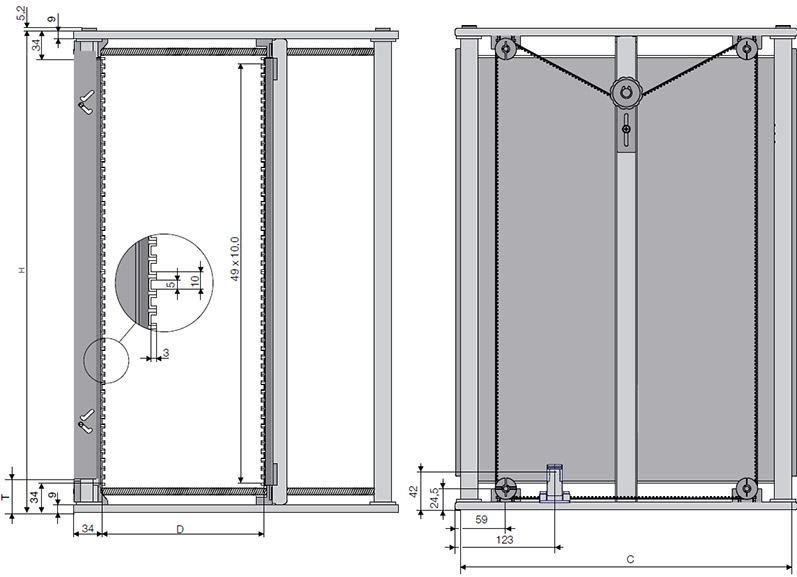

Dimensional drawing Series 6000, 7000 PCB magazines

| Transport lock | Type A | Type B | Type C | |

|---|---|---|---|---|

| T1 | closed | 31.5 | 14 | 19 |

| T2 | open | 39.5 | 22 | 27 |

| T3 | locked | 41.5 | 24 | - |

| Type | PCB | ||||

|---|---|---|---|---|---|

| W mm |

L mm |

H mm |

D mm |

C bis mm |

|

| 6001 7001 |

320 | 355 | 563 | 40 - 250 | 342 |

| 6002 7002 |

320 | 400 | 563 | 40 - 250 | 387 |

| 6003 7003 |

380 | 400 | 563 | 40 - 310 | 387 |

| 7004 | 400 | 460 | 563 | 10 - 330 | 447 |

| 7016 | 460 | 535 | 563 | 10 - 390 | 522 |

| 7017 | 530 | 535 | 563 | 10 - 460 | 522 |

| Type | Side wall material |

Surface resistance |

|---|---|---|

| 600x.1/70xx.1 | Polystyrene | according to DIN EN 61340-5-1 < 1E-9 Ω/cm |

| 600x.2/70xx.2 | Polycarbonate | |

| 600x.3 | Metal | |

| 70xx.3 | Metal |

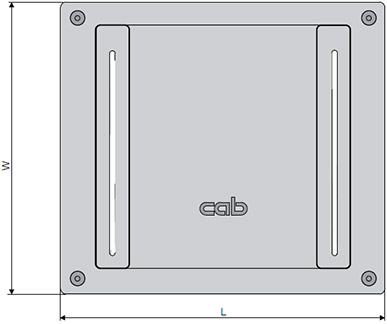

Base plate Series 6000

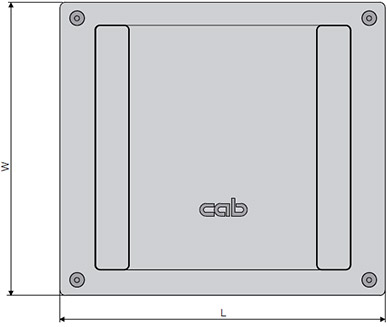

Base plate Series 7000,

Figure: Cast aluminum

Special magazines

Double capacity by parallel insertion

With series 6000 magazines

A maximum load of 100 PCB in one magazine

Magazines with two slide-in units can be used side by side with narrow PCB. Partly assembled magazines have locks B enclosed separately upon delivery. Locks A or C are options.

Side panels: polystyrene, polycarbonate (metal upon request)

Type |

Part No. |

Temperature °C | Weight kg |

Outside dimensions | PCB | ||||

|---|---|---|---|---|---|---|---|---|---|

Slide-ins |

Ambient |

L mm |

B mm |

H mm |

Width D mm |

Length C bis mm |

|||

| 6001.1-P | 8917908 | 60 | 50 | 7.5 | 355 | 320 | 563 | 40 - 100 | 342 |

| 6001.2-P | 8918908 | 130 | 100 | 8.0 | 355 | 320 | 563 | 40 - 100 | 342 |

| 6002.1-P | 8917909 | 60 | 50 | 7.9 | 400 | 320 | 563 | 40 - 100 | 387 |

| 6002.2-P | 8918909 | 130 | 100 | 8.1 | 400 | 320 | 563 | 40 - 100 | 387 |

| 6003.1-P | 8917910 | 60 | 50 | 8.2 | 400 | 380 | 563 | 40 - 130 | 387 |

| 6003.2-P | 8918910 | 130 | 100 | 8.5 | 400 | 380 | 563 | 40 - 130 | 387 |

Low overall heights

With series 6000, 7000 magazines Use, for example, in tempering ovens. Reducing the height also prevents weight overload with heavy PCB or goods carriers. Partly assembled magazines have locks A enclosed separately upon delivery. Locks B or C are options.

Side panels: metal, synthetics

Provided upon request

Documentation

-

Catalogs

-

Title Format Version Last change Language Products for the Electronic Industry

PCB Separators and PCB MagazinesPDF - 3.04 MB 12/2025 13/01/2026 English

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader