Front side applicators 3014, 3016

Labels can be applied in real time from the top or the side to packages

in motion

Front sides or back sides of a package are preferred.

The pad locates in front of the peel-off plate. It picks up a label while it is being printed. The label is transferred to a product with the help of a rotary cylinder. The package is detected by a sensor and the pivot arm with the pad returned to its initial position.

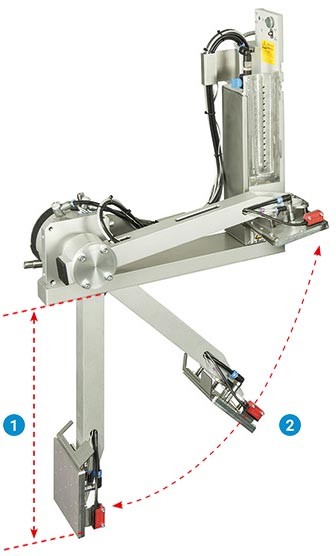

1 Pivot arm length

2 Pivot angle 0 - 90°

Tamp-on pad

Tamp-on pad

Labels are precisely tamped on plane surfaces. Recessed levels are possible as well.

Tamp-on pad, spring-mounted

Tamp-on pad, spring-mounted

Labels can be applied to surfaces inclined by a maximum of 15°. Heights within the area of a label may vary by 10 mm at most.

Blow-on pad

Blow-on pad

Labels are blown on a package surface by a blast of air, bridging a distance of 5 to 10 mm.

Video: Print and Apply System Hermes+ with front-side applicator 3014/3016

We show you features and benefits.

Designed for fully-automated print and apply processes in production lines.

Why are the Hermes print and apply systems in automated manufacturing processes that successful?

The device is designed to use on a cab printer of the HERMES Q and Hermes+ series.

| Technical data | Tamp-on pad | Tamp-on pad, spring-mounted | Blow-on pad | |||

|---|---|---|---|---|---|---|

| 3014, 3016 L/R 1100 | 3014, 3016 L/R 3100 | 3014 L/R 2100 | ||||

| Label widths operating a HERMES Q4/Q4.3 mm Label widthsoperating a HERMES Q6.3 mm |

25 - 114 | 80 - 114 | 25 - 114 | |||

| 25 - 174 | 80 - 174 | - | ||||

| Label heights operating a HERMES Q4/Q4.3 mm Label heights operating a HERMES Q6.3 mm |

8- 250 | 80 - 250 | 10 - 100 | |||

| 25 - 250 | 80 - 250 | 25 - 100 | ||||

| State of a package at the momentat rest a label is applied in motion |

|

|||||

|

||||||

| Label applications from the top from the side from the front from the back |

|

|||||

|

||||||

|

||||||

|

||||||

| Package heights variable |  |

|||||

| Pivot arm length1) mm | 200 / 300 / 400 | |||||

| Pivot angle | 0-90° | |||||

| Weight of applicator using a pivot arm of 200 packaging excluded kg pivot arm of 300 packaging excluded kg pivot arm of 400 packaging excluded kg |

3014 9 |

3016 9,5 |

||||

| 9,5 | 10 | |||||

| 10,5 | 11 | |||||

| Consumption of power W max. | 15 | |||||

| Compressed air bar | 4.5 | |||||

| Cycle rate 2) labels/min approx. | 15 | |||||

Video: Hermes+ front-side applicator 3014 / 3016

Powered by YouTube. See all cab videos: cab channel on YouTube.

Other formats

- Hermes+ front-side applicator 3014/3016 (MPEG-4, 54,7 MB)

- Hermes+ front-side applicator 3014/3016 (WMV, 54,9 MB)

Download players:

- For WMV: Windows Media Player

- For MPEG-4: VLC Player

Documentation

-

Catalogs

-

Title Format Version Last change Language HERMES Q

PDF - 6.90 MB 04/2024 16/04/2024 English

-

-

Assembly Instructions

-

Title Format Version Last change Language Assembly Instructions Front-Side Applicator 3014/3016

PDF - 1.23 MB 09/2023 28/09/2023 English -

Other languages

-

Title Format Version Last change Language Instrukcja obsługi Aplikator od strony czołowej 3014/3016

PDF - 567 KB 10/2017 10/08/2022 Polski Montageanleitung Frontseiten-Applikator 3014/3016

PDF - 1.24 MB 09/2023 28/09/2023 Deutsch Notice d'assemblage applicateur 3014/3016

PDF - 1.20 MB 09/2023 28/09/2023 Français

-

-

-

Service Manuals

-

Title Format Version Last change Language Service Manual Front-Side Applicator 3014/3016 - from SN 9742

PDF - 4.33 MB 10/2021 18/08/2023 English Service Manual Front-Side Applicator 3014/3016 - up to SN 9741

incl. Spare Parts ListPDF - 4.60 MB 06/2017 09/12/2020 English -

Other languages

-

Title Format Version Last change Language Serviceanleitung Frontseiten-Applikator 3014/3016 - ab SN 9742

PDF - 4.72 MB 10/2021 18/08/2023 Deutsch Serviceanleitung Frontseiten-Applikator 3014/3016 - bis SN 9741

inkl. ErsatzteillistePDF - 4.61 MB 06/2017 09/12/2020 Deutsch

-

-

-

Spare Parts

-

Title Format Version Last change Language Spare Parts List Front-Side Applicator 3014/3016 - from SN 9742

PDF - 738 KB 07/2021 18/08/2023 English Service Manual Front-Side Applicator 3014/3016 - up to SN 9741

incl. Spare Parts ListPDF - 4.60 MB 06/2017 09/12/2020 English -

Other languages

-

Title Format Version Last change Language Ersatzteilliste Frontseiten-Applikator 3014/3016 - ab SN 9742

PDF - 743 KB 07/2021 18/08/2023 Deutsch Serviceanleitung Frontseiten-Applikator 3014/3016 - bis SN 9741

inkl. ErsatzteillistePDF - 4.61 MB 06/2017 09/12/2020 Deutsch

-

-

-

Safety data sheets

-

Title Format Version Last change Language Safety Data Sheet Special Cleaner for Glass and Plastic GR1N

PDF - 65 KB 08/2017 02/02/2023 English Safety Data Sheet Special Rubber Cleaner WR1

PDF - 76 KB 12/2017 02/02/2023 English -

Other languages

-

Title Format Version Last change Language Sicherheitsdatenblatt Spezial Glasreiniger und Kunststoffreiniger GR1N

PDF - 156 KB 06/2017 25/08/2022 Deutsch Sicherheitsdatenblatt Spezial-Gummiwalzen-Reiniger WR1

PDF - 173 KB 06/2017 25/08/2022 Deutsch

-

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

We offer Hermes Q 3D CAD models with different applicators in stp file format.

Well-trained cab service engineers worldwide support in the maintenance and repair of the devices.