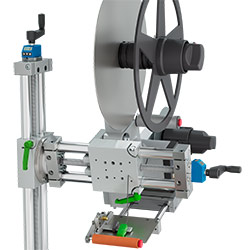

Labeling head

IXOR+

for precise insert labeling

Labeling head IXOR+

Mechanical unwinders and rewinders

for label webs running as fast as 50 m/min

Roll diameters 310 mm and 410 mm

Unwinders and demand units can be assembled also independent from a base unit

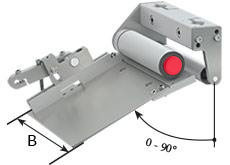

Vertical assembly position:

The sleeve core is extended by 62 mm relative to the rewinder to accommodate and clamp the counterholder. The labeling head can also be mounted horizontally.

Horizontal assembly position:

There is no counterholder. The sleeve cores of the unwinder and rewinder are the same length.

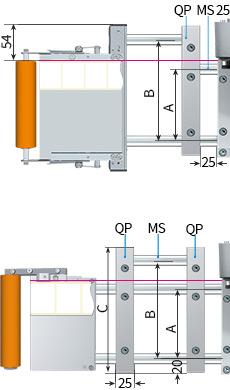

- 50 D 410 V 124 L labeling head

410 mm maximum label roll diameter

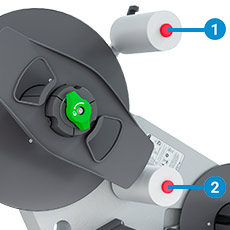

1 Rewinder

The liner is wound when labels have been dispensed. A pendulum arm and an integral clutch keep the liner under constant tension in subsequence to the drive roller.

2 Unwinder

picking up label rolls with a maximum diameter of 410 mm. A pendulum arm and an integral brake keep a label web under constant tension.

3 Sleeve retainer

Turning the handle tensions and releases the label roll sleeve.

4 Unit retainers

for securing and guiding a label roll when installed in vertical orientation. For this purpose, the sleeve retainer is designed 62 mm longer than in horizontal installation.

5 Base unit

It is the center of a labeling head and contains the drive roller for feeding a label web, a brushless servo motor and the system control including the operation panel.

6 Operation panel

Color 3.5" LCD touchscreen , rotation by 180° enables overhead installation.

7 Pick-up spots

for assembly onto columns with a diameter of 30 mm. Label positions on a product can thus be set transversely to its direction of running.

8 Demand unit

It can be configured for specific applications using a comprehensive modular system.

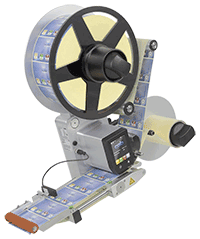

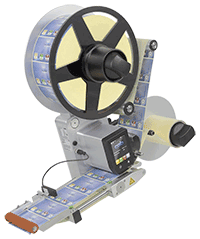

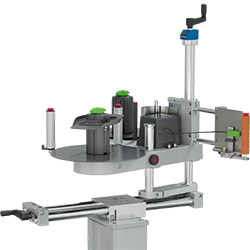

Labeling head IXOR+

Motoric unwinders and rewinders

for label webs running as fast as

- 75 m/min with a mechanical unwinder, motoric rewinder

- 120 m/min with a motoric unwinder and a motoric rewinder, 200 m/min upon request

Roll diameter 410 mm (510 mm upon request)

Modular construction:

A base unit, unwinder and rewinder are installed on a mounting strip. The modules can be positioned also on a carrier plate according to customer specifications.

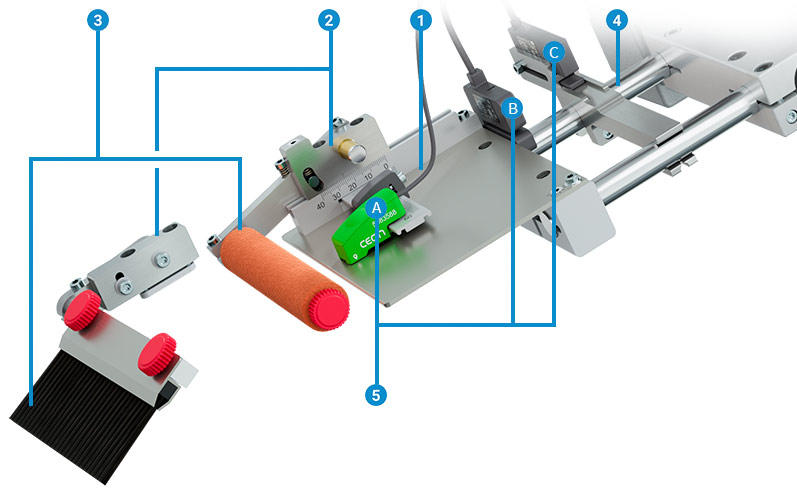

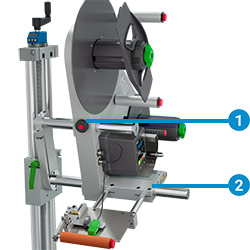

- 120 D 410 V 124 L labeling head

410 mm maximum label roll diameter

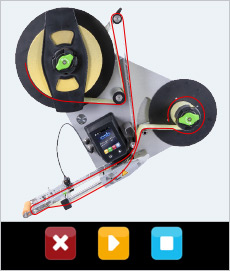

1 Mechanical or motoric unwinder

picking up label rolls with a maximum diameter of 410 mm (510 mm upon request). With a motoric unwinder in use, the roll is driven by an integral brushless torque motor. The label web unwinds according to the pendulum arm. A label web speed is automatically activated as soon as the motoric unwinder has been connected.

2 Counterholder

for securing and guiding a label roll when installed in vertical orientation. For this purpose, the sleeve retainer is designed 62 mm longer than in horizontal installation.

3 Mounting strip

for assembling a base unit, motoric unwinder, rewinder

4 Deflection rollers

They are guiding a label web from a motoric unwinder to the base unit.

5 Pick-up spots

for assembly onto a column stand.

Label positions on a product can thus be set transversely to its direction of running.

6 Motoric rewinder

The liner is wound when labels have been dispensed. A pendulum arm and an integral brushless torque motor keep a label web under constant tension in subsequence to the drive roller. Any kind of installation is possible. A label web speed is automatically activated as soon as the motoric rewinder has been connected.

7 Base unit

It is assembled to the mounting strip. A PowerBus module is installed for connecting motoric winders.

8 Demand unit

It can be configured specific to applications using a comprehensive modular system.

cab systems developed for printing and applying labels provide proper features by default, fairly protecting your data in a network.

Operation panel

Intuitive and easy to operate. Rotatable by 180°, depending on the installation of a unit.

Unit configuration with the help of selfexplanatory symbols on the user interface

Quick menu

1 Stop delay

2 Start delay

3 Label web speed

ON / OFF Pre-dispense

4 Status bar

Speed, label winding,

length of label feed,

WLAN, start / stop signal

5 Operational and warning notes

Status and menu parameters

6 Counter and diagnostics

Configurable specified to an application

7 Settings

Settings

Label web speed

Label web speed

Synchronicity with speed of items

System settings

System settings

Display, language, label web ending, interfaces

Label position on an item

Label position on an item

Multiple labeling

Start condition

User configuration

User configuration

Any number of formats

Backup and restore by a PC

Label stop on a demand module

Label stop on a demand module

Missing labels detected

Processing an external stop condition

Charge counter

Charge counter

Automatic stop subsequent to a specified number of items

Print settings

Print settings

Control of an external printer

or a label transfer module

Service tools

Service tools

Maintenance assistant, video tutorials, input and control of digital I/O for service purposes

Label transfer settings

Label transfer settings

Control of optional applicators,

air jet boxes, etc.

Firmware

Embedded Linux operating system

- Support 'out-of-the-box' of Open Source bundles and interfaces, such as FTP, SSL, Avahi/Zeroconf

- Regular updates for hotfixes and official CVE security patches

- Comprehensive release notes with each update

Compatibility of labeling heads

- Same codebase on ROXI and IXOR+

- Identical firmware file in preparation

- Further developments are immediately available on every unit.

Maintenance and diagnostics

![]()

- Web Interface

- Event log for activity tracking

- Diagnostics files in standardized XML text format

Interfaces and user-specific features

| USB stick | Web interface |

FTP software | |

|---|---|---|---|

| Access to entire documentation of a unit |

|

|

|

| Backup and restore |  |

|

|

| Configuration reading and import |

|

|

|

| Firmware update |  |

|

Upgrades

- Protocols such as MQTT as well as features like the masterencoder can be unlocked by key (online purchase).

Remote support

- Diagnostics service by use of an existing customer network

- Special software oscilloscope, maximum resolution 1 ms, for unlimited use during production

Integral Ethernet protocols for higher-level machine control systems

- MQTT, ModBus TCP

- OPC UA

- Profinet available from quarter 1/2026

- Access via PLC and an industrial PC to parameters, I/O signals, error messages

- Unlocked by key

Redundancy

- Two labeling heads can be operated redundantly and continually in an Ethernet network.

- While one dispenser actively applies labels onto items, another unit is on standby. In cases of a malfunction on an active unit (e.g. a label web ending), the second takes over immediately.

- All items located between the units are labeled.

- The product sensor and the rotary encoder each are provided once for both labeling heads. Signals are transmitted to both labeling heads via a distributor.

- An adapter is required for Ethernet connection.

- Unlocked by key

VNC LAN / WLAN

VNC LAN / WLANRemote control by a PC, smartphone, tablet

Feed path schemes

Feed path schemesOn display

Interfaces

1 END/DIM: Mechanical unwinder sensor input

Prior warning to a label web ending, label web ending, broken liner

2 Ethernet: TCP/IP data transfer

I/O: Compliant to IEC/EN 61131-2, type 1+3 All inputs and outputs protect from reverse polarity. Outputs are also short-circuit proof.

I/O: Compliant to IEC/EN 61131-2, type 1+3 All inputs and outputs protect from reverse polarity. Outputs are also short-circuit proof.

Digital inputs

Labeling head ON

Pre-dispense

Start labeling

Start labeling locked

Error reset

User-defined

Analog inputs

Speed

Start delay

Stop delay

Digital PNP outputs

Labeling head ready

Pre-dispense

Stop label feed

Label feed running

Label missing on liner

End of label web

Prior warning to label web ending

Error

User-defined

Status indications on the operation panel

all inputs and outputs

Helpful with initial setup, especially when integrating a labeling head in external control systems

Inputs and outputs can be simulated or forced for testing purposes.

START: By signal, for example a product sensor

START: By signal, for example a product sensor

5 APPLY: USB host (via adapter cable) Peripheral interface for plugging a printer and controlling a transfer unit according to

I/O, configurable with two inputs and one output Compliant to IEC/EN 61131-2, type 1+3. All inputs and outputs protect from reverse polarity.

Outputs are also short-circuit proof. An external operation panel or a warning light may be as well plugged.

SYNC: A label web is synchronized by a masterencoder (rotary → linear upon request) to the speed of an item on a conveyor

SYNC: A label web is synchronized by a masterencoder (rotary → linear upon request) to the speed of an item on a conveyor

7 POWER IN: Input voltage 100 V to 240 V, 50 Hz to 60 Hz

8 WLAN: integral to the operation panel

PRINT & APPLY

PRINT & APPLY

Peripheral interface for plugging a printer and controlling a transfer unit with 24 VDC

STOP

STOP

Plug of a label sensor for detecting the leading edge of a label optically or inductively

Motoric unwinder, rewinder

11 PowerBus IN

Input voltage 100 V to 240 V, 50 Hz to 60 Hz

12 PowerBus OUT

Output voltage 100 V to 240 V, 50 Hz to 60 Hz

Plug and PIN assignment compatible with ROXI

Plug and PIN assignment compatible with ROXI

| Width of a roll IXOR+mm max. | 62 | 124 | 186 |

|---|---|---|---|

| Label web speed when operating mechanical unwinder, rewinder m/min max. |

50 |

||

| mech. unwinder, motoric rewinder m/min max. | 75 | ||

| motoric unwinder, rewinderm/min max. | 120 (200 upon request) | ||

| Cycle rate labels/min | It is determined by the length of a label and the speed of an item running on a conveyor and can be simulated on the operation panel. | ||

| Installation | vertical / horizontal | ||

| Direction to which labels are provided | L = to the left, R = to the right | ||

| Material1) | |||

| Label on a roll | paper, synthetics PET, PE, PP, PVC / booklets upon request | ||

| Label Widthmm | 10 - 58 | 10 - 120 | 10 - 182 |

| Label Length at feedingmm | 10 - 6,000 | ||

| Label Gap mm at least | 2 | ||

| Label Thicknessmm | 0.055 - 1.0 | ||

| Liner Widthmm | 15 - 62 | 15 - 124 | 15 - 186 |

| Roll Weightkg max. | 15 | ||

| Unwinder Outside diametermm | mechanical 310, 410 / motoric 410 (510 upon request) | ||

| Unwinder Core diametermm | 76 | ||

| Unwinder Winding | outside or inside | ||

| Rewinder Outside diameter mm | mechanical 210, 290 / motoric 310 (410 upon request) | ||

| RewinderCore diametermm | 92 | ||

| Label sensor | |||

| Features | detection of label margins and materials ending | ||

| Distance to locating edge CEON mm | 9 - 30 | 9 - 60 | 9 - 90 |

| Distance to locating edge GAB 500-1 mm | 7.5 - 17.5 | ||

| Distance to locating edge GAB 500-2 mm | 8 - 40 | ||

| Operating data | |||

| Voltage | 100 - 240 V~, 50 - 60 Hz | ||

| Current consumption | 100 VAC up to 5 A / 240 VAC 2,5 A | ||

| Temperature / humidity Operation | 0 - 40 °C / 10 - 85 % not condensing | ||

| Temperature / humidity Stock | 0 - 60 °C / 20 - 80 % not condensing | ||

| Temperature / humidity Transport | –25 - 60 °C / 20 - 80 % not condensing | ||

| Approvals | CE, FCC Class A, ICES-3, cULus, CB | ||

| Protection class | IP 66 | ||

| Operation panel | |||

| LED | ON / OFF, FEED | ||

| LCD graphics display Width x Height mm | 54 x 70 | ||

| Control | |||

| Prior warning to a label web ending, label web ending, broken liner torque, temperature, voltage | |||

- Limitations can occur when processing small labels, thin materials or materials using a strong adhesive. Such applications require testing.

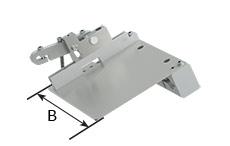

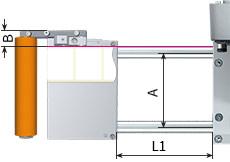

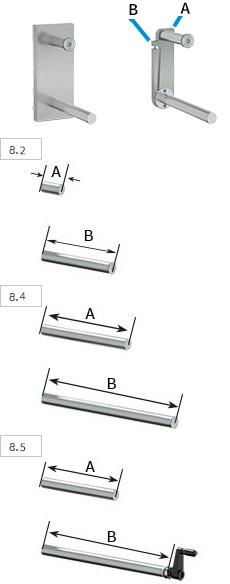

| Dimensions A mm |

Dimensions B mm Installation |

||

|---|---|---|---|

| vertical | horizontal | ||

| Width of a roll | 62 | 163 | 163 |

| 124 | 225 | 163 | |

| 186 | 287 | 225 | |

| Demand module | Dimensions C mm |

|---|---|

| SP | 19 |

| SPE | 24 |

| SPFA | 19 |

| Mounting rod | Dimensions L1 mm |

|---|---|

| MS 25 | 25 |

| MS 100 | 100 |

| MS 200 | 200 |

| MS 300 | 300 |

| MS 400 | 400 |

Scopes of delivery, designs and technical data correspond to the date of this publication. They are subject to change. Catalogue data do not represent any warranty or guarantee.

Ready to interact with machines and components of different manufacturers in industrial plants.

Which accessories fit to which model you can see in overview all accessories IXOR+ product catalog.

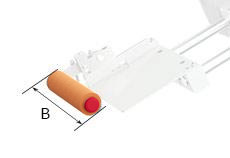

UR D60 deflection rollers

Deflection rollers 1 and 2 with a diameter of 60 mm help with materials that detach from a liner material when bent at a tight radius.

| Types | Diameters mm | Widths B mm | |

|---|---|---|---|

| Deflection roller | UR D60/62 | 60 | 62 |

| UR D60/124 | 60 | 124 | |

| UR D60/186 | 60 | 186 | |

| Guide | FR D60 | - | - |

2 cannot be installed on an IXOR+ base unit

Anti-stick-coated deflection rollers can be provided upon request.

Documentation

-

Catalogs

-

Title Format Version Last change Language Labeling heads ROXI, IXOR+

PDF - 4.37 MB 02/2026 09/02/2026 English Overview Product Marking

PDF - 6.70 MB 01/2026 20/01/2026 English

-

-

Programming

-

Title Format Version Last change Language Brief introduction to cab printer programming

PDF - 7.47 MB 04/2022 15/01/2025 English cabPROTECT - Data security in label printing

PDF - 472 KB 06/2024 20/06/2024 English -

Other languages

-

Title Format Version Last change Language cabPROTECT - Datensicherheit beim Etikettendruck

PDF - 475 KB 06/2024 20/06/2024 Deutsch Kurze Einführung in die cab Druckerprogrammierung

PDF - 7.50 MB 04/2022 12/04/2022 Deutsch Marquage en réseau avec OPC UA

cab et l'usine intelligentePDF - 745 KB 01/2022 23/10/2024 Français

-

-

-

Manuals Accessories

-

Title Format Version Last change Language Montageanleitung CEON / Mounting Instruction CEON

PDF - 300 KB 01/2025 15/09/2025 English/Deutsch

-

-

Case study

-

Title Format Version Last change Language cab labeling heads, operated by Ankerkraut and GERNEP

Spices known from Die Höhle der Löwen, labeled in a professional wayPDF - 928 KB 06/2022 22/01/2025 English Covid-19 rapid test: A combination of machines providing, labeling and packing

PDF - 771 KB 08/2020 25/08/2022 English When precision is the target: Feeding, labeling and packing PCR tests

PDF - 859 KB 11/2021 25/08/2022 English

-

-

Safety data sheets

-

Title Format Version Last change Language Safety Data Sheet Special Cleaner for Glass and Plastic GR1N

PDF - 65 KB 08/2017 23/10/2024 English Safety Data Sheet Special Rubber Cleaner WR1

PDF - 76 KB 12/2017 23/10/2024 English -

Other languages

-

Title Format Version Last change Language Sicherheitsdatenblatt Spezial Glasreiniger und Kunststoffreiniger GR1N

PDF - 156 KB 06/2017 25/08/2022 Deutsch Sicherheitsdatenblatt Spezial-Gummiwalzen-Reiniger WR1

PDF - 173 KB 06/2017 25/08/2022 Deutsch

-

-

3D CAD models

The files are provided in STEP format, which requires CAD software. Follow this link to download a free STP Viewer: VariCAD Viewer (External website).

Select the desired model and click on the link. A short registration follows. cab will handle your personal information as described in our Privacy statement. This information will not be accessible to any third party for marketing purposes. You will receive an email with an activation link and you can download the models.

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Well-trained cab service engineers worldwide support in the maintenance and repair of the devices.

Software & Drivers

-

Firmware

-

Title Format Version Last change Language Release Notes Firmware IXOR

TXT - 36 KB

TXT - 36 KB

1.09 - 1.45.6 07/01/2026 English -

Other languages

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 – Firmware IXOR

GZ - 61.48 MB 1.45.6 07/01/2026 –

-

-

-

Firmware periphery

-

Title Format Version Last change Language cabFirmwareUpdater

Windows 32 & 64 bit (starting from Vista)ZIP - 21.75 MB 3.12.0.0 26/03/2025 –

-

You need Adobe Reader to view the PDF-files. Download current version of Adobe Reader

Ready to interact with machines and components of different manufacturers in industrial plants.

Standard

Standard